506303-01

Page 32 of 40 Issue 0938

It is recommended that this furnace be inspected by a

qualified service technician at the beginning of each heating

season.

Filters

Filters should be checked at least every 6 weeks. Disposable

filters should be replaced when dirty, and cleanable filters

should be cleaned regularly. It is important to keep the air

filters clean, as dirty filters can restrict airflow and the blower

and induced draft motors depend upon sufficient air flowing

across and through them to keep from overheating.

Lubrication

The blower motor and induced draft motor are pre-lubricated

by the manufacturer and do not require further lubricating

attention. However, the motors should be cleaned periodically

to prevent the possibility of overheating due to an accumulation

of dust and dirt on the windings or on the motor exterior.

MAINTENANCE

Condensate Collection and Disposal System

Check the condensate drain line periodically for blockage.

Visual inspection of condensate flow can be done easily

while the furnace is in operation. Use a flashlight to illuminate

the discharge end of the condensate drain that is placed in

the sewer opening. If the condensate drain line becomes

blocked or plugged, the furnace will not operate properly.

Burners

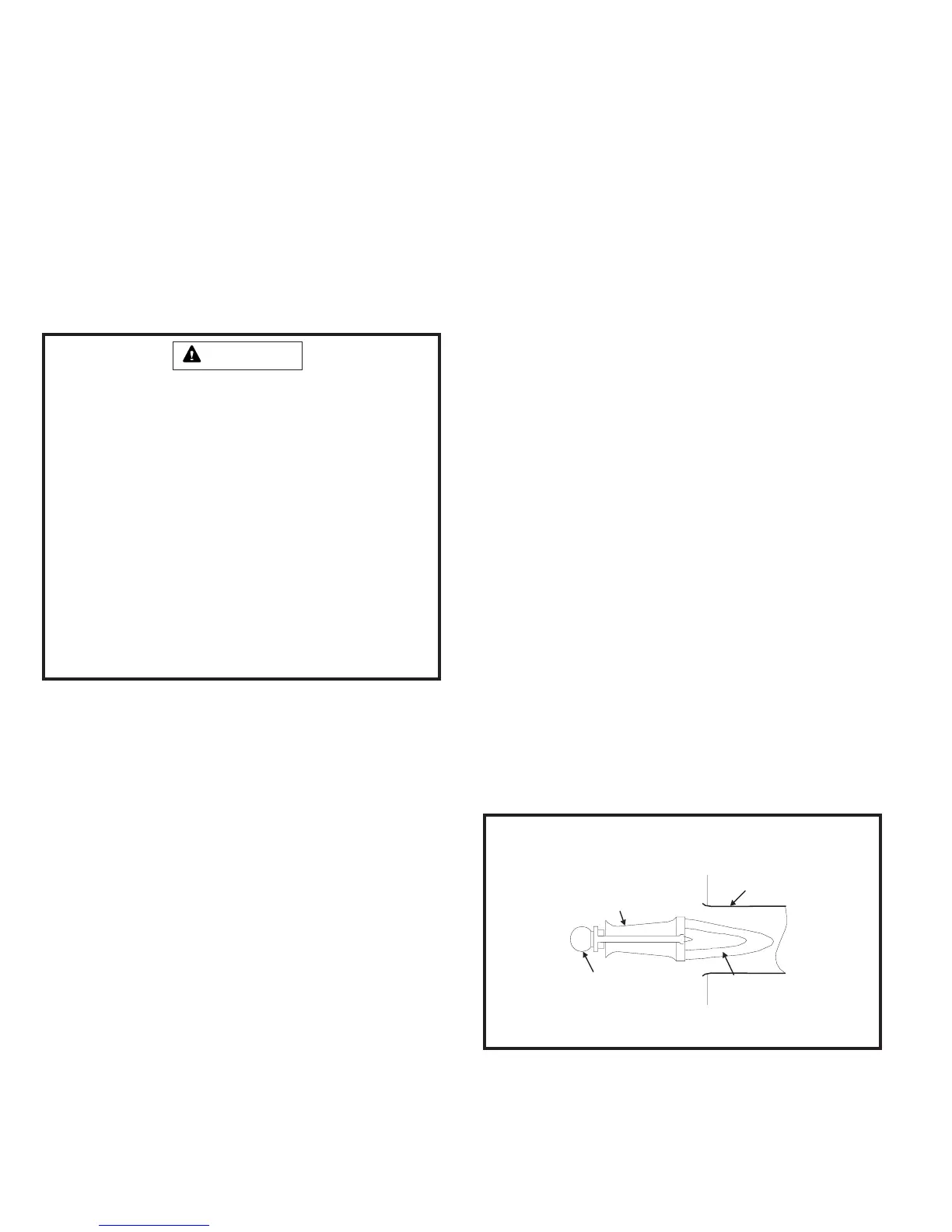

Light the burners and allow to operate for a few minutes to

establish normal burning conditions. Observe the burner

flames. Compare this observation to Figure 43 to determine if

proper flame adjustment is present. Flame should be

predominantly blue in color and strong in appearance. Check

that all burners are lit, and that the flame does not impinge on

the sides of the heat exchanger.

Distorted flame or yellow tipping of the natural gas burner

flame, or long yellow tips on propane, may be caused by

lint accumulation or dirt inside the burner or burner ports, at

the air inlet between the burner and manifold pipe, or

obstructions over the burner orifice.

Use a soft brush or vacuum to clean the affected areas.

Connect the desired speed tap to the “EAC” terminal and

the neutral tap to the neutral terminal on the ignition control

(refer to the furnace wiring diagram). The ignition control

will control the motor’s operation, including a nominal 20-

second “on” delay with a call for heat and a nominal 180-

second “off” delay when the thermostat is satisfied. It will

also operate the motor on a call for cooling, with no “on” or

“off” delays.

Verify that the unit is operating at the desired speed and

within the rise range as shown on the unit rating plate.

The correct replacement motor must be installed as

soon as possible to ensure continued satisfactory

operation of the furnace.

Failure to follow the safety warnings exactly could result

in dangerous operation, serious injury, death, or property

damage.

Improper servicing could result in dangerous operation,

serious injury, death, or property damage.

• Before servicing, disconnect all electrical power to

furnace.

• When servicing controls, label all wires prior to

disconnecting. Reconnect wires correctly.

• Verify proper operation after servicing.

WARNING

ELECTRICAL SHOCK, FIRE,

OR EXPLOSION HAZARD

Typical Flame Appearance

Figure 43

Heat

Exchanger

Burner

Flame

(Blue Only)

Burner

Gas

Manifold

Loading...

Loading...