506303-01 Page 21 of 40Issue 0938

If local codes allow the use of a flexible gas appliance

connector, always use a new listed connector. Do not use a

connector which has previously serviced another gas

appliance.

Pipe connections must be tight, and a non-hardening pipe

compound resistant to liquefied petroleum gases should

be used.

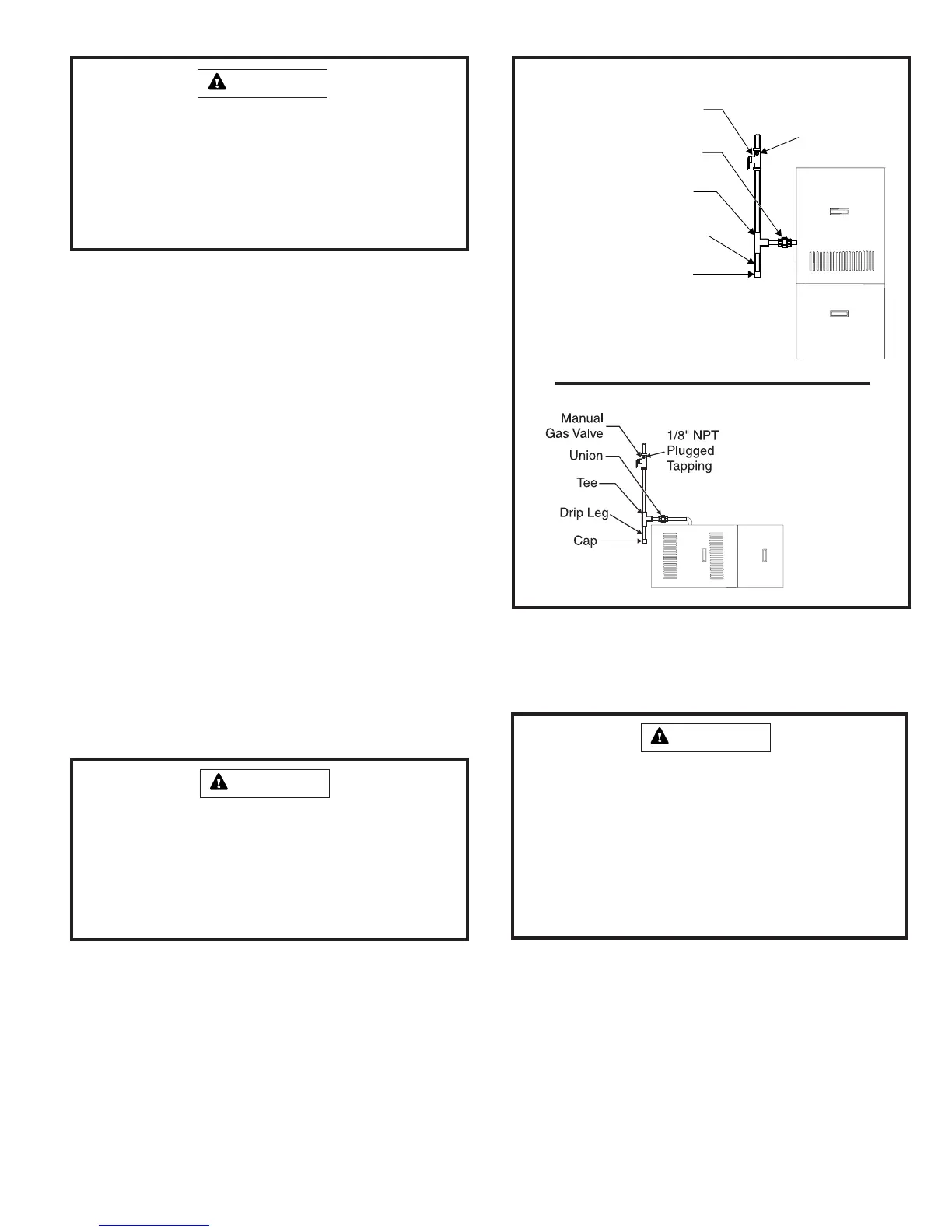

Connect the gas pipe to the furnace controls providing a

ground joint union as close to the controls as is possible to

facilitate removal of controls and manifold. Provide a drip

leg on the outside of the furnace. A manual shutoff valve

shall be installed in the gas line, outside the unit, 5' above

the floor, or in accordance with any local codes. A test gauge

connection must be installed with a 1/8" NPT plugged

tapping immediately upstream of the shutoff valve (see

Figure 32).

The furnace must be isolated from the gas supply piping

system by closing the individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressure equal to or less than 1/2 psig (3.5 kPa) or 14"

W.C. If the piping system is to be tested at pressures in

excess of 1/2 psig (3.5 kPa), the furnace and its appliance

main gas valve must be disconnected from the gas supply

piping system.

After gas piping is complete, carefully check all piping

connections (factory and field) for gas leaks. Use a leak

detecting solution or other preferred means. Some soaps

used for leak detection are corrosive to certain metals.

Carefully rinse piping thoroughly after leak detection has

been completed.

Any conversion of a natural gas unit to propane gas must

be done by qualified personnel using a conversion kit

available from the manufacturer, following the instructions

in the conversion kit. If done improperly, overfiring of the

burners and improper burner operation can result. This

can create carbon monoxide which could cause

asphyxiation.

WARNING

The gas valve supplied with this furnace is rated at 1/2

psig maximum. Any higher pressure may rupture the

pressure regulator diaphragm and may cause overfiring

of the burners and improper burner operation. The

overfiring may result in the creation of carbon monoxide

which could cause asphyxiation.

WARNING

Failure to follow the safety warnings exactly could result

in serious injury, death, or property damage.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically

for the detection of leaks to check all connections. A

fire or explosion may result causing property damage,

personal injury, or loss of life.

WARNING

FIRE OR EXPLOSION HAZARD

Gas Piping Connection

Figure 32

Manual

Gas Valve

Union

Te e

Drip Leg

Cap

1/8" NPT

Plugged

Tapping

Upflow

Installation

Horizontal

Installation

Loading...

Loading...