506303-01 Page 31 of 40Issue 0938

For Natural Gas: Check the furnace rate by observing the

gas meter, when available, making sure all other gas

appliances are turned off. The test hand on the meter should

be timed for at least one revolution. Note the number of

seconds for one revolution.

x

3600

x

=

Cubic Feet Per RevolutionBTU/HR

INPUT # Seconds Per Revolution

Heating

Value

The heating value of the gas can be obtained from the local

utility company.

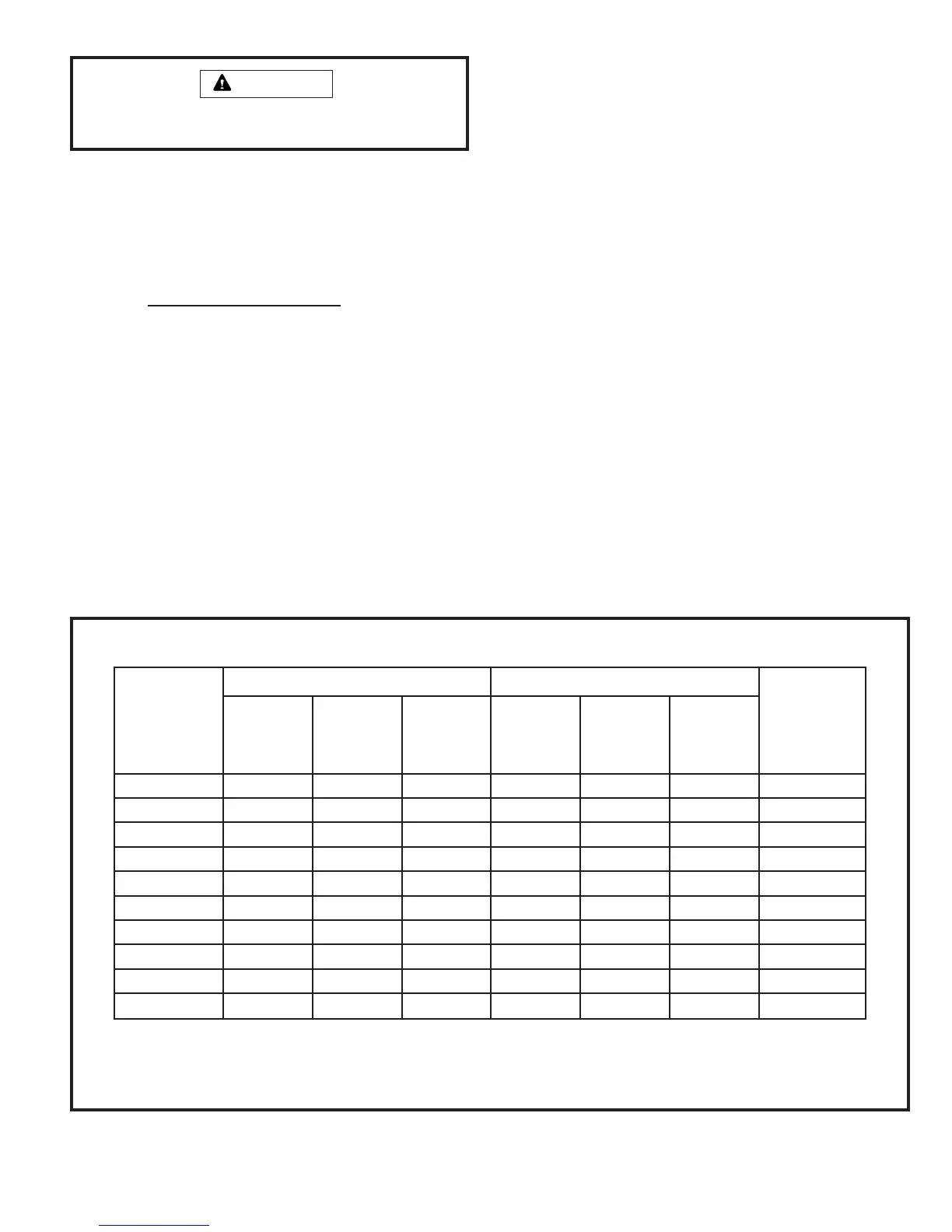

For Propane Gas: The only check for the furnace rate is to

properly adjust the manifold pressure using a manometer and

Table 4. Typical manifold set point for installations at altitudes

from 0 to 4500 feet above sea level is 10.0" W.C.

Temperature Rise

Check the temperature rise and, if necessary, adjust blower

speed to maintain temperature rise within the range shown

on the unit rating plate.

The furnace rate must be within +/- 2% of the appliance

rating input.

CAUTION

High Altitude

In both the United States and Canada, this furnace is approved

for operation at altitudes from 0 to 4500' above sea level

without any required modifications. From 4500' to 7500', the

gas manifold pressure needs to be adjusted according to the

information shown in Table 4. To adjust the manifold pressure,

refer to section Checking and Adjusting Gas Input. For

installations above 7500', call Technical Service at 1-800-448-

5872 for assistance.

For installations above 4500 feet fill in the appropiate

information on the furnace label that has the words “This

furnace was converted on . . . . . . . . “.

For installation above 4,000 ft. refer to seciton Vent Pipe Size

and Length on page 7 and Figure 4 on page 7 Vent Pipe

Sizing.

Emergency Replacement Motor Operation (G2D95CT/

U Models Only)

If the variable speed motor in a G2D95CT/U furnace needs to

be replaced in an emergency situation (such as “no heat”)

and an exact replacement motor is not immediately available,

a standard PSC motor of equivalent frame size, voltage,

rotation, and horsepower can be temporarily installed until

the correct replacement motor can be obtained.

Manifold Pressure vs. Altitude

Table 4

* Consult local utility for actual heating value.

Furnace Input = Input Factor x Nameplate Input

Above 7500 feet, call Technical Services at 1-800-448-5872.

Altitude

(ft.)

Natural Gas

Propane

Heating

Value*

(Btu/ft³)

Manifold

Pressure

Low Fire

(in. w.c.)

Manifold

Pressure

High Fire

(in. w.c.)

Heating

Value*

(Btu/ft³)

Manifold

Pressure

Low Fire

(in. w.c.)

Manifold

Pressure

High Fire

(in. w.c.)

Input

Factor

2000

3000

4000

4500

5000

5500

6000

6500

7000

7500

948

914

881

865

849

833

818

802

787

771

1.70

1.70

1.70

1.70

1.61

1.60

1.59

1.58

1.57

1.56

3.50

3.29

3.27

3.25

3.23

3.21

3.19

3.50

3.50

3.50

2278

2196

2116

2077

2039

2000

1964

1927

1891

1853

4.90

4.90

4.90

4.90

4.61

4.58

4.55

4.53

4.50

4.47

10.00

10.00

10.00

10.00

9.41

9.35

9.29

9.24

9.18

9.12

0.9666

0.9499

0.9332

0.9249

0.8900

0.8790

0.8680

0.8570

0.8460

0.8350

Loading...

Loading...