506303-01

Page 4 of 40 Issue 0938

Unconfined Space

An unconfined space is defined as “a space whose volume

is more than 50 cubic feet per 1000 BTU per hour of the

combined input rating of all appliances installed in that

space.” When a furnace is installed in an unconfined space

in a building, it can be assumed that the infiltration will be

sufficient to supply the required air. If the furnace is installed

in a ventilated attic or crawl space, it is assumed that the

infiltration is sufficient to supply the required air. However,

in a building of unusually tight construction, additional

outdoor air should be provided.

• The return air duct must be provided and sealed to the

furnace.

• Return air temperature range between 60°F and 80°F

must be maintained.

• Air filters must be installed in the system and must be

maintained during construction.

• Air filters must be replaced upon construction

completion.

• The input rate and temperature rise must be set per

the furnace rating plate.

• One hundred percent (100%) outdoor air must be

provided for combustion air requirements during

construction. Temporary ducting may supply outdoor

air to the furnace. Do not connect duct directly to the

furnace. Size the temporary duct following the

instructions given on this page in the Combustion and

Ventilation Air section regarding confined space with

air from outside.

• The furnace heat exchanger, components, duct system,

air filters, and evaporator coils must be thoroughly

cleaned following final construction cleanup.

• All furnace operating conditions (including ignition, input

rate, temperature rise, and venting) must be verified

according to these installation instructions.

G2D93CT and G2D95CT models installed in the horizontal

position are approved for attic installations. If the furnace

is to be installed in an attic or other insulated space, it

must be kept free and clear of insulating materials.

Clearances

All servicing and cleaning of the furnace can be performed

from the front. If installed in a closet or utility room, provide

18" clearance in front for service if the door to the room is

not in line with the front of the furnace.

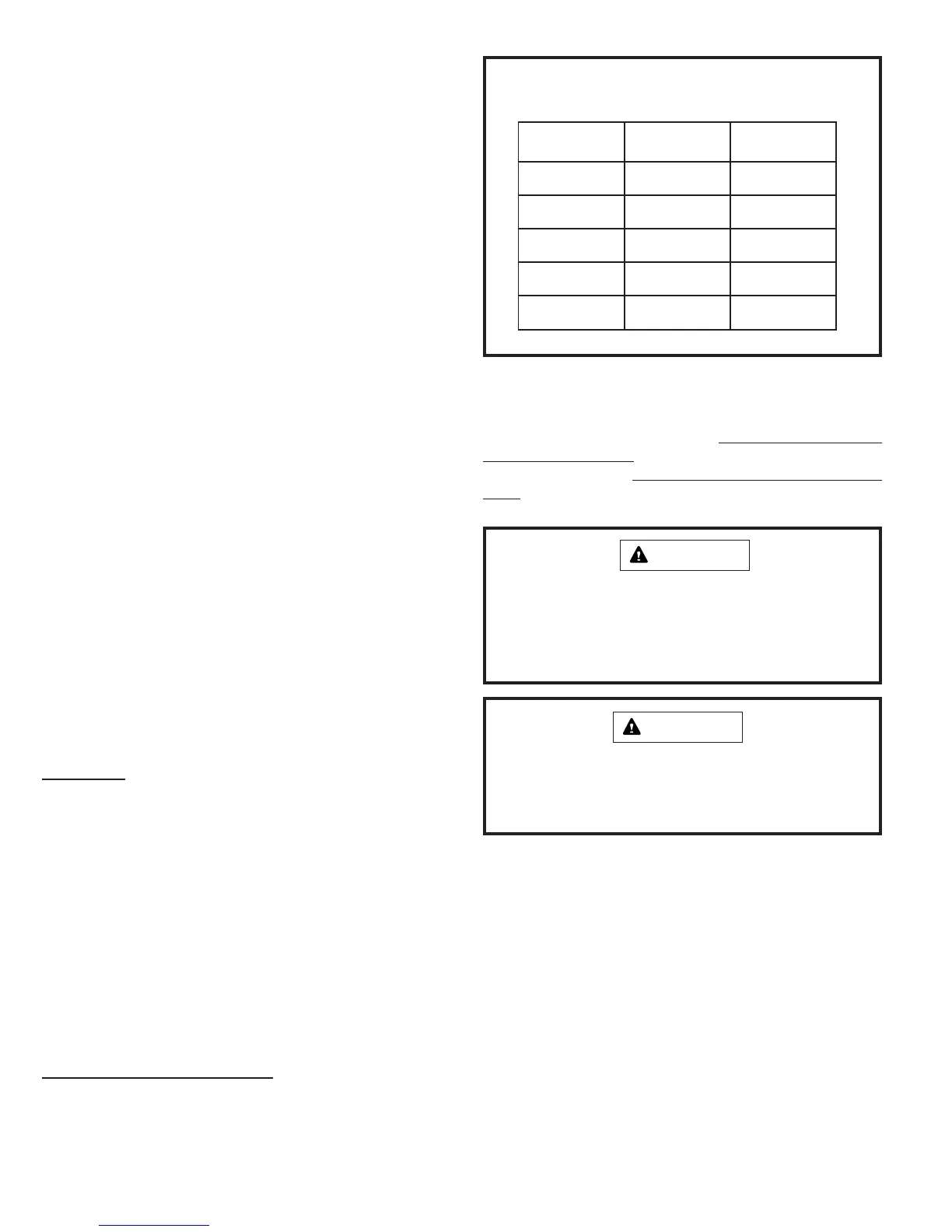

Refer to Table 1 for the minimum clearances to combustibles

required for construction and proper unit operation. Where

servicing clearances are greater than clearances to

combustibles, servicing clearances take precedence.

G2D93CT and G2D95CT models may be installed on wood

flooring but shall not be installed directly on carpeting, tile, or

any other combustible material.

Combustion and Ventilation Air

Adequate provisions for combustion air and ventilation of

furnace must be made. Refer to Section 5.3, “Air for

Combustion and Ventilation,” of the National Fuel Gas Code,

ANSI Z223.1/NFPA54 (latest edition), Sections 7.2, 7.3, or

7.4 of CSA B149.1 Natural Gas and Propane Installation

Codes (latest editions), or applicable provisions of the local

building codes.

Insufficient combustion air can cause headaches, nausea,

dizziness, or asphyxiation. When considering combustion

air requirements, enough air must also be provided to

meet the needs of all fuel-burning appliances and exhaust

fans.

WARNING

Air openings in the front of the furnace must be kept free

of obstructions. Any obstruction may cause improper

operation that can result in a fire hazard or carbon

monoxide injury.

WARNING

Table 1

Minimum Clearances to

Combustibles

Upflow Horizontal

Sides

0” 0”

Rear 0” 0”

2”

18”

0”

0”

1” 1”

Front

Flue Pipe

Plenum

Loading...

Loading...