2 Application information

2.1 Welding instructions

SMD 's I/O pads are made of copper leadframe

planar substrates, except that these pads are

exposed to the outside for mechanical and electrical

connections. When used, both the I/O pad and the

exposed pad need to be soldered to the PCB . To

prevent oxidation and optimize soldering, the solder

joints on the bottom of the sensor are plated with

Ni/Au.

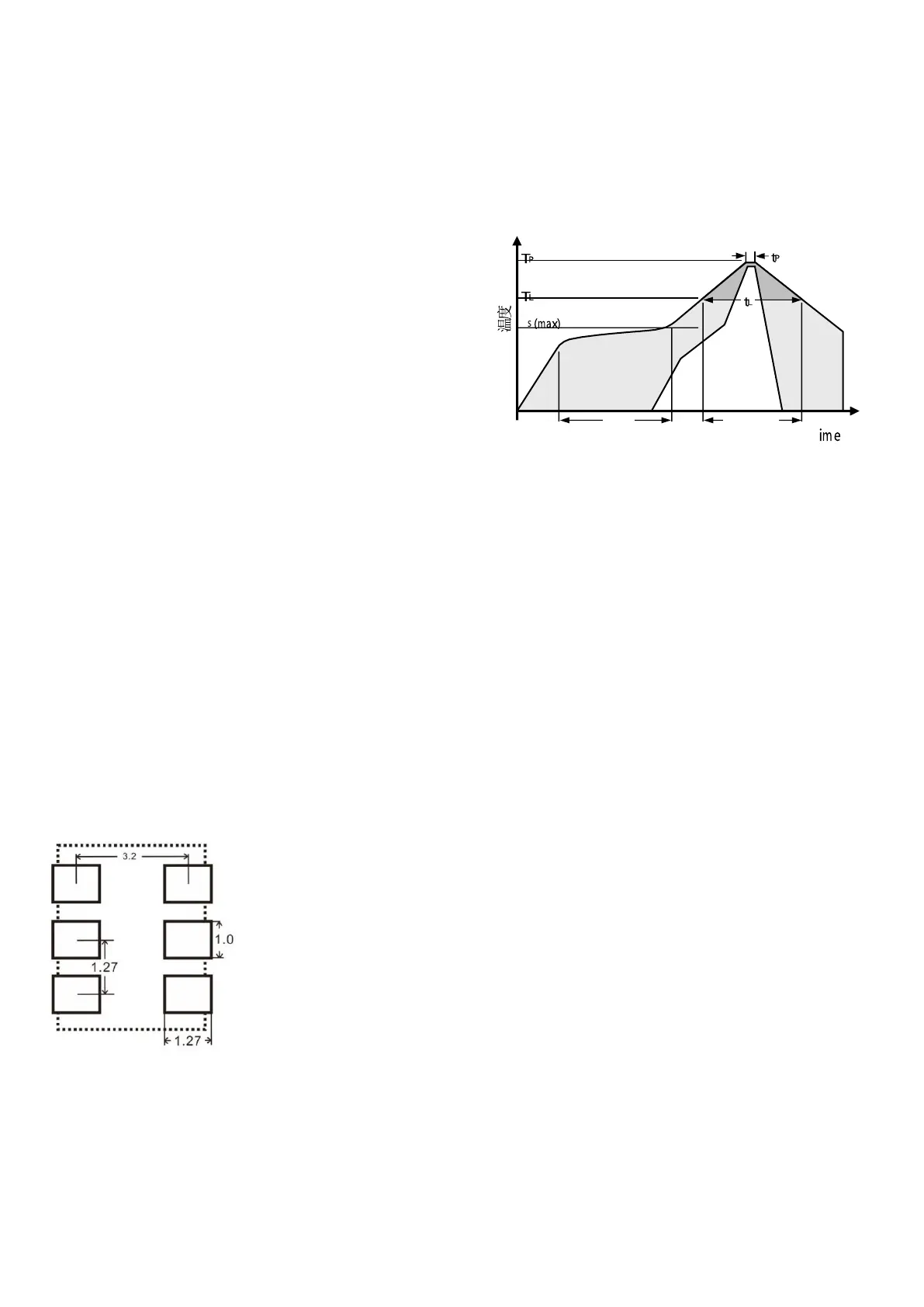

On the PCB, I / O contact surface length should / O

pads package is larger than the AHT10 I 0.2mm, to

the portion on the inner side of the I / O pads to

match the shape, and the width of the lead width

ratio SMD pads of the package 1:1, see Figure 8 .

For stencil and solder mask design [7] It is

recommended to use a copper foil definition pad (

SMD ) with a solder mask opening larger than the

metal pad .

For the SMD pad, if the gap between the copper foil

pad and the solder resist layer is 60 μm - 75 μm , the

solder mask opening size should be larger than the

pad size 120 μm - 150 μm . The rounded portion of

the package pad is matched to the corresponding

round solder mask opening to ensure that there is

sufficient solder mask area (especially at the

corners) to prevent solder from intersecting. Each

pad must have its own solder mask opening to form

a solder mask network around the adjacent pads.

Figure 8 recommends the AHT10 PCB design dimensions (unit: mm), peripheral

The dotted line is the outer dimensions of the SMD package.

For solder printing, it is recommended to use a laser-

cut stainless-steel mesh with an electronically

polished trapezoidal wall. The recommended mesh

thickness is 0.125mm . The stencil size for the pad

portion must be 0.1 mm longer than the PCB pad .

And placed at a distance of 0.1mm from the center of

the package . The stencil of the exposed pad is

covered

70%-90% of the pad area — that is, 1.4mmx2.3mm at

the center of the heat sink area . Due to the low

placement height of SMD , it is recommended to use

no-clean type 3 solder. and purify with nitrogen

during reflow.

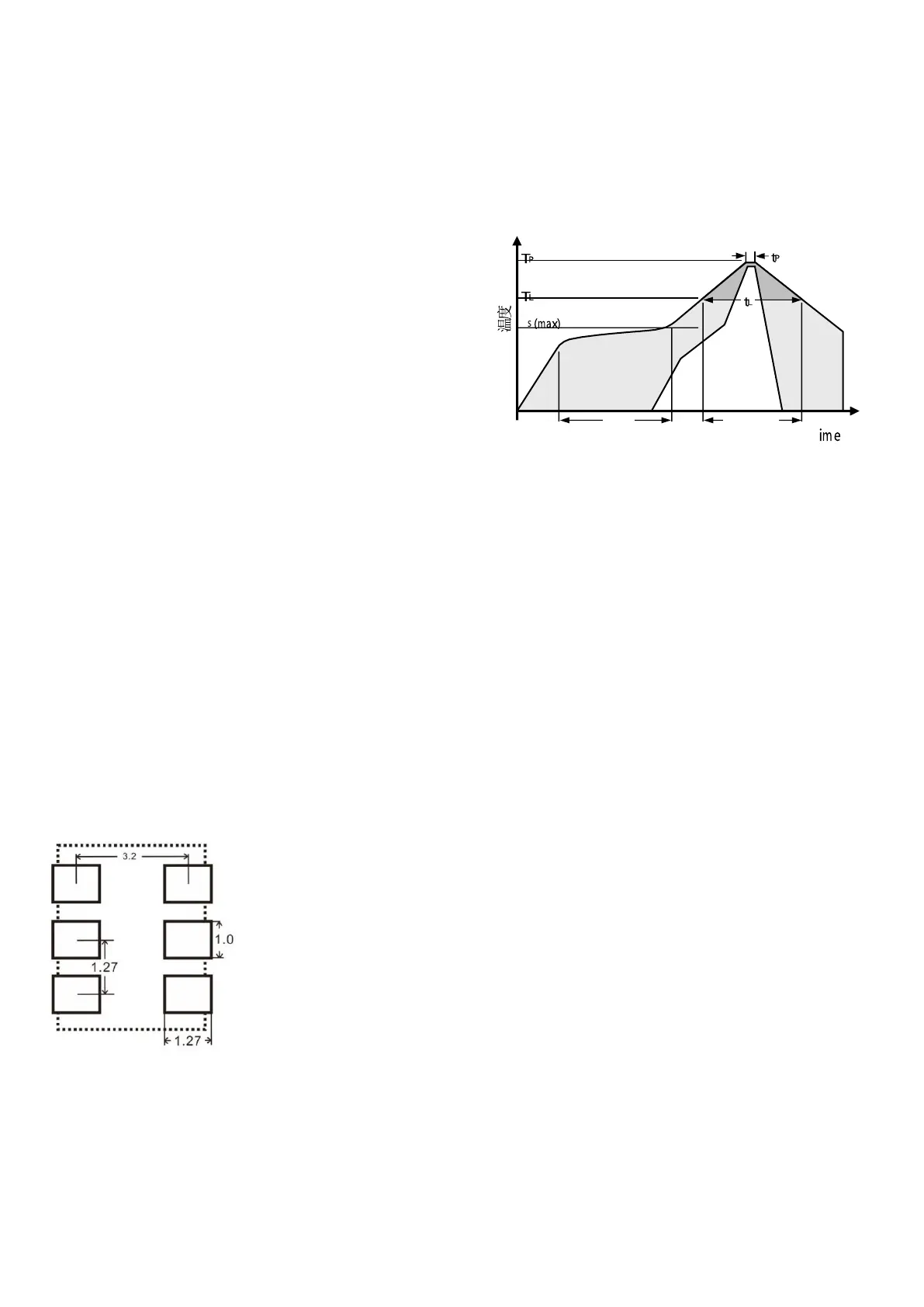

Figure 9 JEDEC standard welding process diagram, Tp <= 260 ° C, tp < 30 sec ,

lead-free soldering Pick up. TL<220°C, tl<150sec , the rate of temperature rise

and fall during welding Should be <5 ° C / sec .

The AHT10 can be soldered using a standard reflow

oven . The sensor is fully compliant with the IPC/JEDEC

J-STD-020D soldering standard. The contact time

should be less than 40 seconds at temperatures up to

260 °C ( see Figure 9) ; the ultimate soldering

temperature that the sensor can withstand is 260 °C .

Note: After reflow soldering, the sensor should be

stored in a >75% RH environment for at least 12 hours

to ensure rehydration of the polymer. Failure to do so

will cause the sensor reading to drift. It is also possible

to place the sensor in a natural environment ( >40%

RH ) for more than 5 days to rehydrate it. Use low

temperature reflow soldering

(Example : 180 ° C) can reduce hydration time.

Do not flush the board after soldering. Therefore, customers are advised

to use " no-clean " solder paste. If the sensor is used in corrosive gases

or if condensed water is produced (eg, in a high-humidity environment),

both the lead pad and the PCB need to be sealed (eg, using a conformal

coating) to avoid poor contact or short circuit.

Loading...

Loading...