Page 3 of 4 I&M No. V_5993_R8

©

ASCO Valve, Inc.

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

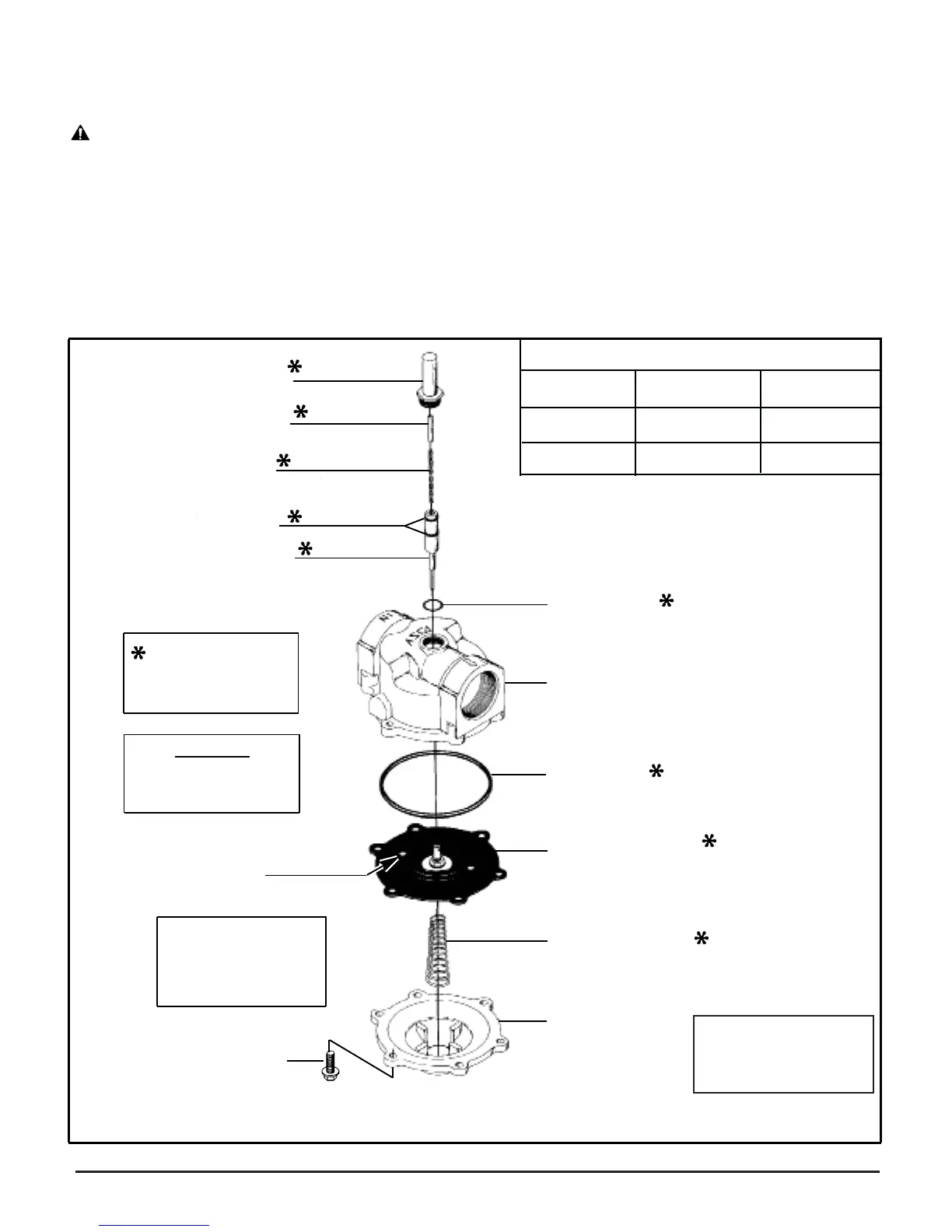

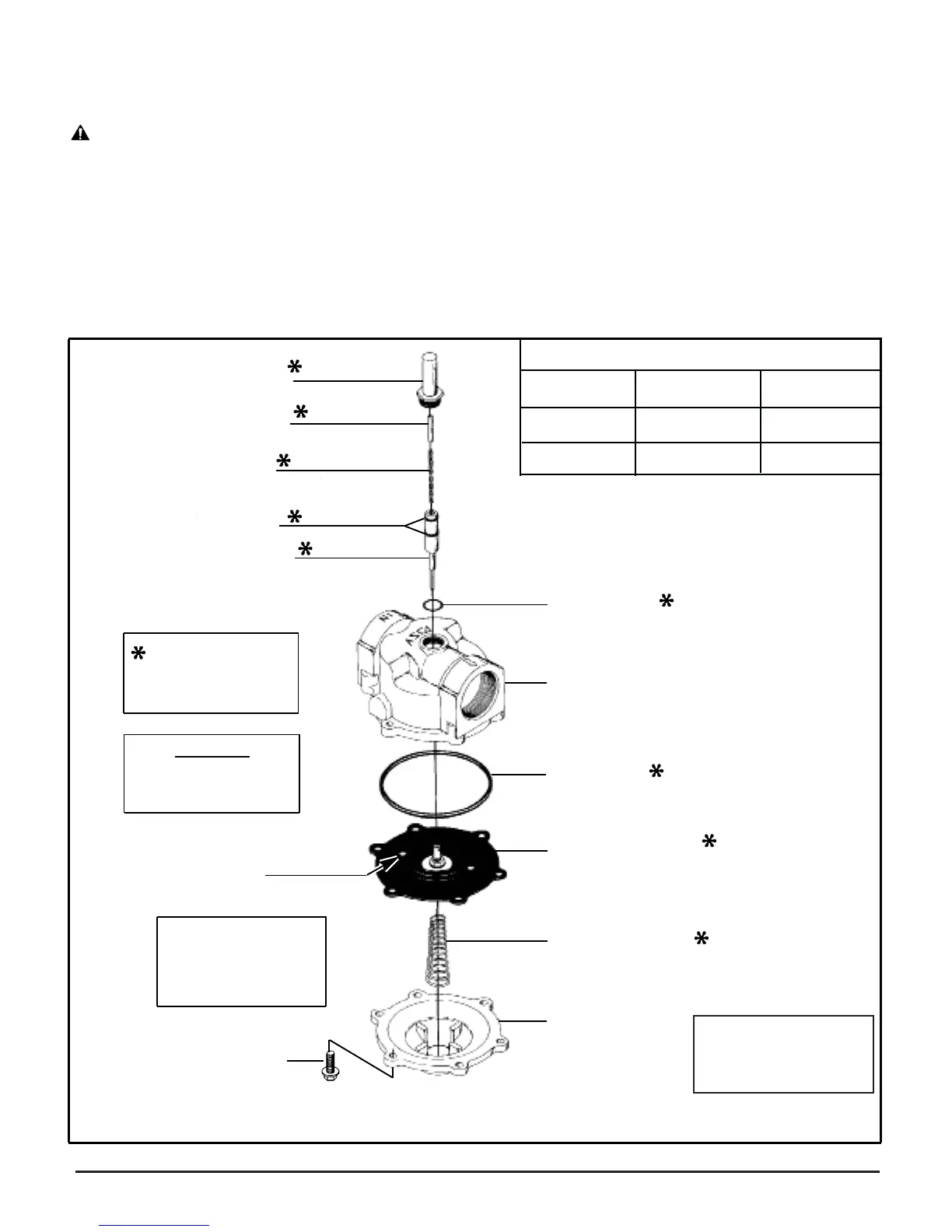

solenoid base

sub-assemb

ly

spring retainer

core spring

rider rings (2)

core assembly

CAUTION

Do not damage valve

seat in any manner

bleed hole

Locate bleed hole in

diaphragm assembly

approximately 30°

from valve outlet

bonnet screw

Part Name

Solenoid Base

Sub-Assembly

Bonnet Screws

Torque Chart

Torque Value

45±5 ft-lbs

100±10 in-lbs

bonnet gasket

valve body

body gaske

t

diaphragm assembly

diaphragm spring

(wide end to face

valve bonnet)

See Note1

valve bonnet

Figure 1. For Series 8215 AC and 8215G DC Constructions

(AC shown)

Torque Value

Newton-Meters

61±1 6,8

11,3±1,1

Indicates Parts

Supplied in ASCO

Rebuild Kit

13. Replace valve bonnet and bonnet screws, start all bonnet

screws by hand. Torque bonnet screws in a crisscross

manner to 100 ± 10 in-lbs (11,3, ± 1, 1Nm). If necessary,

make up piping and fi nal electrical hookup.

WARNING: To prevent the possibility of

death, serious injury or property damage,

check valve for proper operation before

returning to service. Also perform internal

seat and external leakage tests with a

nonhazardous, noncombustible fl uid.

14. Restore line pressure and electrical power supply to valve.

15. After maintenance is completed, operate the valve a few

times to be sure of proper operation. A metallic “click”

signifi es the solenoid is operating.

ORDERING INFORMATION

FOR ASCO REBUILD KITS

Parts marked with an asterisk (*) in the exploded view are

supplied in Rebuild Kits.

•When Ordering Rebuild Kits for ASCO valves, order the

Rebuild Kit number stamped on the valve

nameplate.

+ If the number of the Rebuild Kit is not visible order them

and specify your valve’s Catalog Number and Serial Number.

Note1: For 8215083,

the spring is

assembled in reverse

of what is shown.

Loading...

Loading...