I&M No.V7533

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 2 of 3

Periodic exercise of the valve should be considered if ambient or

fluid conditions are such that corrosion, elastomer degradation,

fluid contamination build up, or other conditions that could

impede solenoid valve shifting are possible. The actual frequency

of exercise necessary will depend on specific operating conditions.

A successful operating history is the best indication of a proper

interval between exercise cycles.

Depending on the medium and service conditions, periodic

inspection of internal valve parts for damage or excessive wear is

recommended. Thoroughly clean all parts. If parts are worn or

damaged, install a complete rebuild kit.

Causes Of Improper Operation

Incorrect Pressure: Check valve pressure. Pressure to valve must

be within range specified on nameplate.

Excessive Leakage: Disassemble valve and clean all parts. If parts

are worn or damaged, install a complete ASCO Rebuild Kit.

Valve Disassembly

1. Disassemble valve in an orderly fashion using exploded views for

identification of parts.

2. Remove solenoid, see separate instructions.

3. Unscrew solenoid base sub-assembly and remove body gasket,

core assembly, core spring and core guide (core guide not

present on all constructions).

4. All parts are now accessible to clean or replace. Replace worn

or damaged parts with a complete ASCO Rebuild Kit.

Valve Reassembly

1. Reassemble valve using exploded views for identification and

placement of parts.

2. Lubricate solenoid base gasket with DOW CORNING 111

Compound lubricant or an equivalent high-grade silicone

grease.

3. Replace body gasket and install core assembly,core spring and

core guide (if present) into solenoid base sub-assembly.

4. Replace solenoid base sub-assembly (with core assembly) into

valve body. Torque solenoid base sub-assembly to 175$25

in-lbs. [19,8$2,8 Nm].

5. Install solenoid, see separate instructions and make electrical

connections.

WARNING: To prevent the possibility of

death, personal injury or property damage, turn

off electrical power, depressurize valve, and vent

fluid to a safe area before servicing the valve.

6. Restore line pressure and electrical power supply to valve.

7. After maintenance is completed, operate the valve a few times

to be sure of proper operation. A metallic click signifies the

solenoid is operating.

ORDERING INFORMATION

FOR ASCO REBUILD KITS

Parts marked with an asterisk (*) in the exploded views are supplied

in Rebuild Kits. When Ordering Rebuild Kits for ASCO valves,

order the Rebuild Kit number stamped on the valve nameplate. If the

number of the kit is not visible, order by indicating the number of kits

required, and the Catalog Number and Serial Number of the valve(s)

for which they are intended.

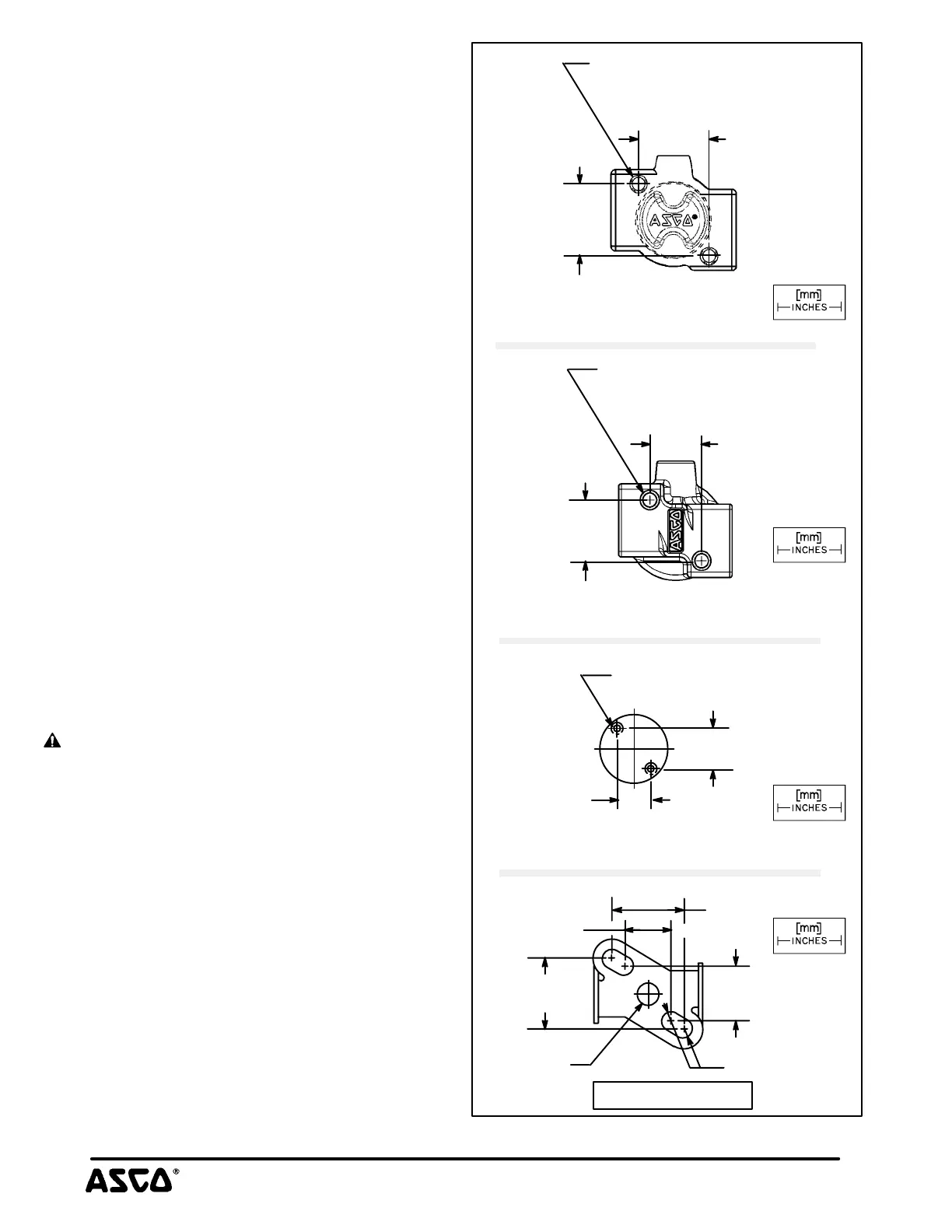

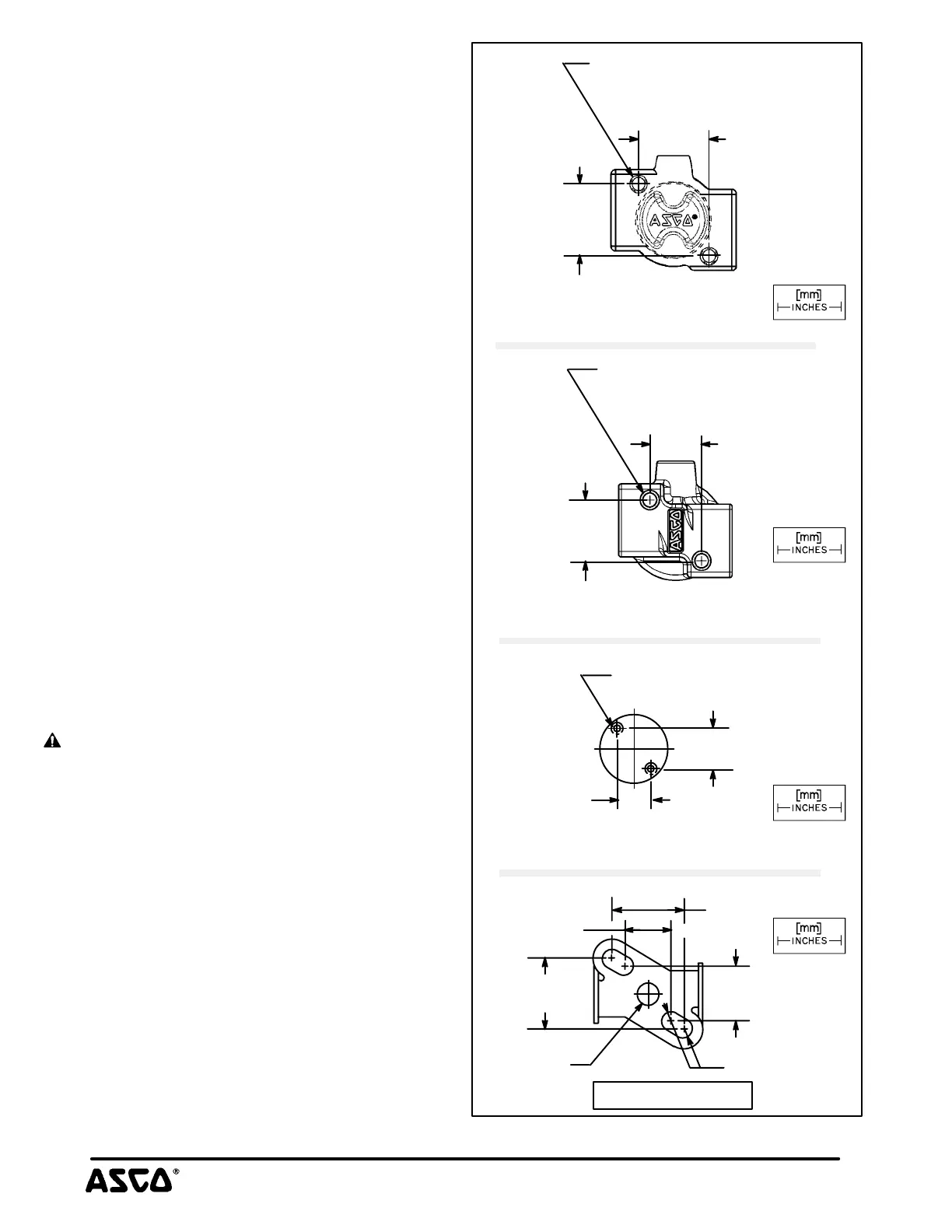

[3,2]

.125 R (4 places)

[Ø6,8]

.266 dia.

[22]

.88

[15]

.59

[17]

.68

[22]

.86

Mounting Bracket

.59

.69

1/4 NPT

1/8 NPT

[22,2]

[22,2]

.875

.875

brass & stainless steel

2 mounting holes .190-32

UNF-2B, .50 [12,7] deep

.31 [7,9] min. full thread

2 mounting holes .190-32

UNF-2B, .38 [9,7] deep

.25 [6,4] min. full thread

[15,1]

[17,5]

brass

1/8 NPT

stainless steel

[17]

.688

.190-32 UNF-2Bx.44 [11] deep

2 holes for mounting

[15,0]

.592

Loading...

Loading...