IM14229-9

Setpoint input : 0 ... 10 V (100 kOhm input resistance)

0 ... 20 mA / 4 ... 20 mA (250 Ohm input resistance)

Feedback output : 0 ... 10 V (max. 10 mA), short-circuit protected

0 ... 20 mA / 4 ... 20 mA (max. 24 VDC)

Digital output : pnp; open collector; max. 200 mA/4.8W, short-circuit protected

HIGH (24 VDC) if feedback=setpoint

LOW (open) if feedback≠setpoint

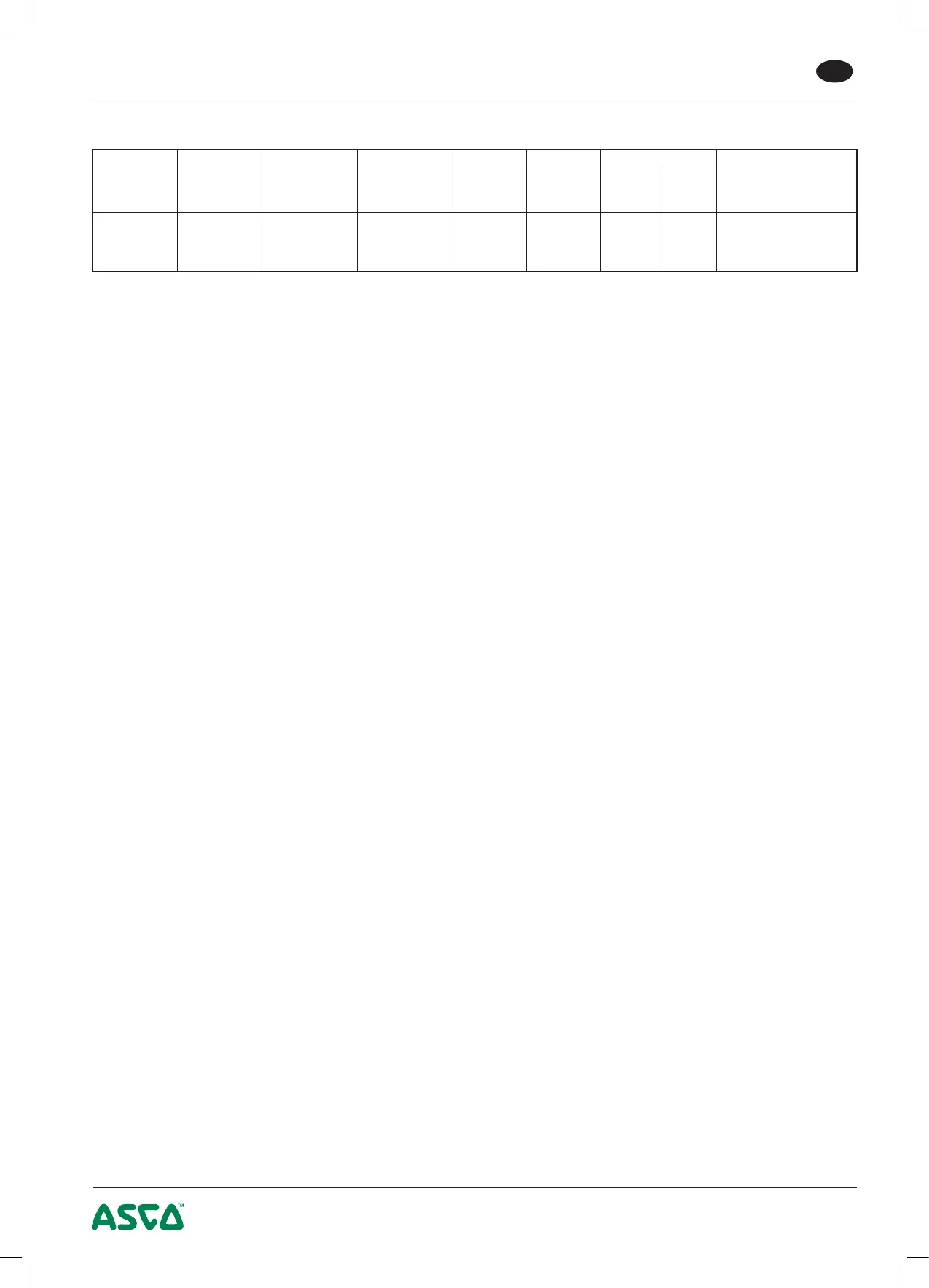

5.2 SPECIFICATIONS

Nominal

diameter

DN

(mm)

Supply

voltage

(1)

(stabilised)

Max. power

(W)

Max. current

(mA)

Insulation

class

Degree of

protection

Flow

(2)

Electrical connections

K

V

(Nm

3

/h)

at 6 bar

(l/min

ANR)

3

6

12

20

24 V=

+/-10%

12

24

34

44

500

1000

1400

1800

F IP 65

0,18

0,60

1,20

4,80

210

700

1400

5600

5-pin female M12 connector

or

7-pin female DIN connector

(1) Residual ripple: 10 %

(2) Test conditions according to ISO 8778: temperature: 20 °C, relative inlet pressure: 6 bar, relative outlet pressure: 5 bar

INSTALLATION AND OPERATING INSTRUCTIONS

1. Before putting into operation carefully check all electrical connections and the supply voltage (24 VDC ±10 %).

Overload can destroy the electronics. Recommended pre-fuse T2.0 A.

2. The electrical connection is made with a round connector M12x1. The connector must meet the requirements of

DIN 60079-15. The product was tested with connector catalogue no. 88100729.

In order to ensure conformity with ATEX Directive 2014/34/EU, the product must be installed in such a manner as

to protect the electrical connector from mechanical stress.

WARNING:

Do not disconnect the connector while under voltage!

When disconnected from power, use supplied protection cover to ensure IP protection.

3. Use shielded cables for the electrical connection of the valve. The shield, connector and control cabinet must be

EMC compliant. The valve body must be electrically connected to ground (PE, machine ground). Do not run con-

trol cables parallel to high-voltage lines, servo-motor control cables etc.

4. Min. wire cross-section of supply voltage cable: 0.50 mm

2

.

For longer cabling distances use larger cross-section cables as required.

5. Make sure that the valve is under pressure when a setpoint signal is applied to the valve (applying a setpoint signal

with no pressure on the valve will cause it to overheat).

6. The valve is factory adjusted.

7. The product must be returned to the factory for repair.

Loading...

Loading...