Internal tack welding of the tank valve:

1. Place the tank valve into a pre-drilled hole so that the tank valve is flush with the

inner surface of the dish.

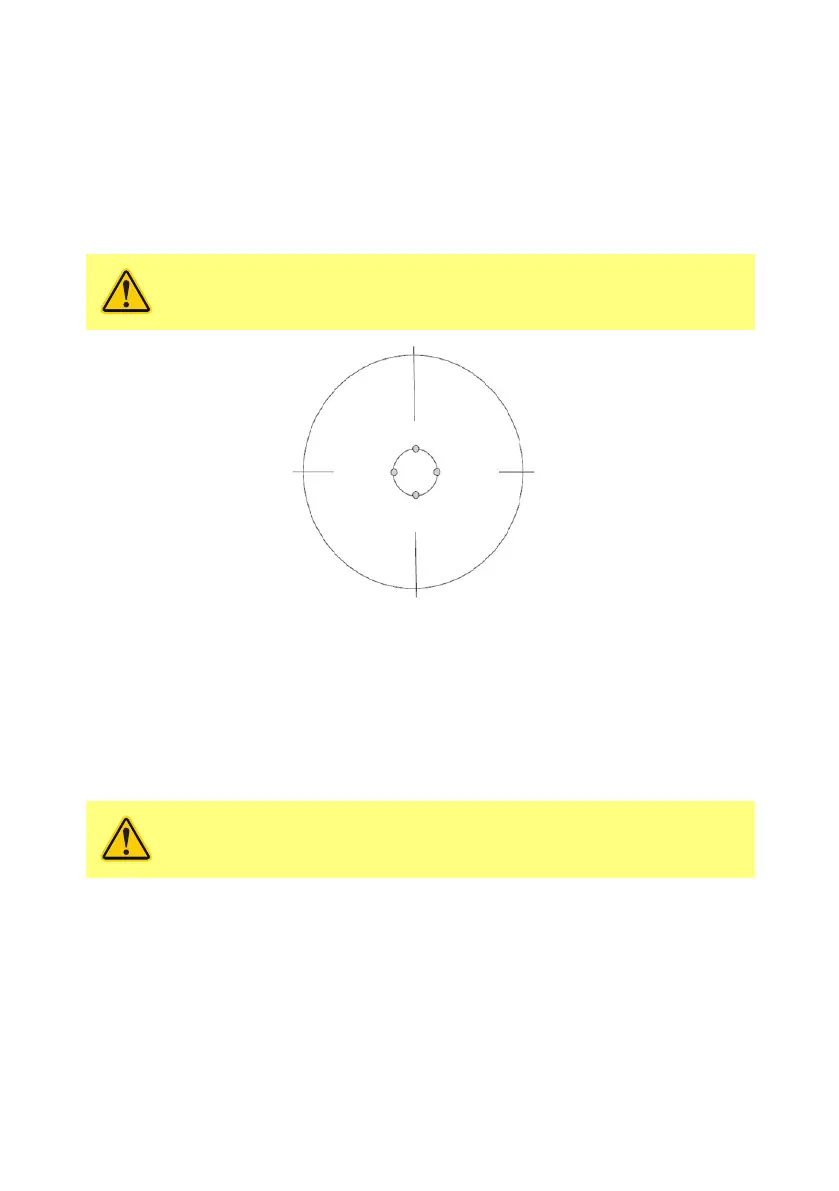

2. Tack weld at A and B (shown below). Check the inner surface to ensure the valve is

flush.

3. Make necessary corrections if necessary.

4. Tack weld at C and D (shown below).

Follow above instructions. Do not overheat the material.

Tack Welding from INSIDE the vessel head

13.7 External tack welding of the tank valve:

1. Start with the dished head turned upside down on a clean working surface and fill it

with protective gas (keep the gas flowing during the welding process).

2. Tack weld the tank valve as follows:

a) Start with A then B then C then D per figure 1.7

b) Next follow the numbers as indicated 1 through 12 below

Follow above instructions. Do not overheat the material.

m-radialdiaphragmvalve-en-02 41

Loading...

Loading...