IO-123075 Effective 12-01-11

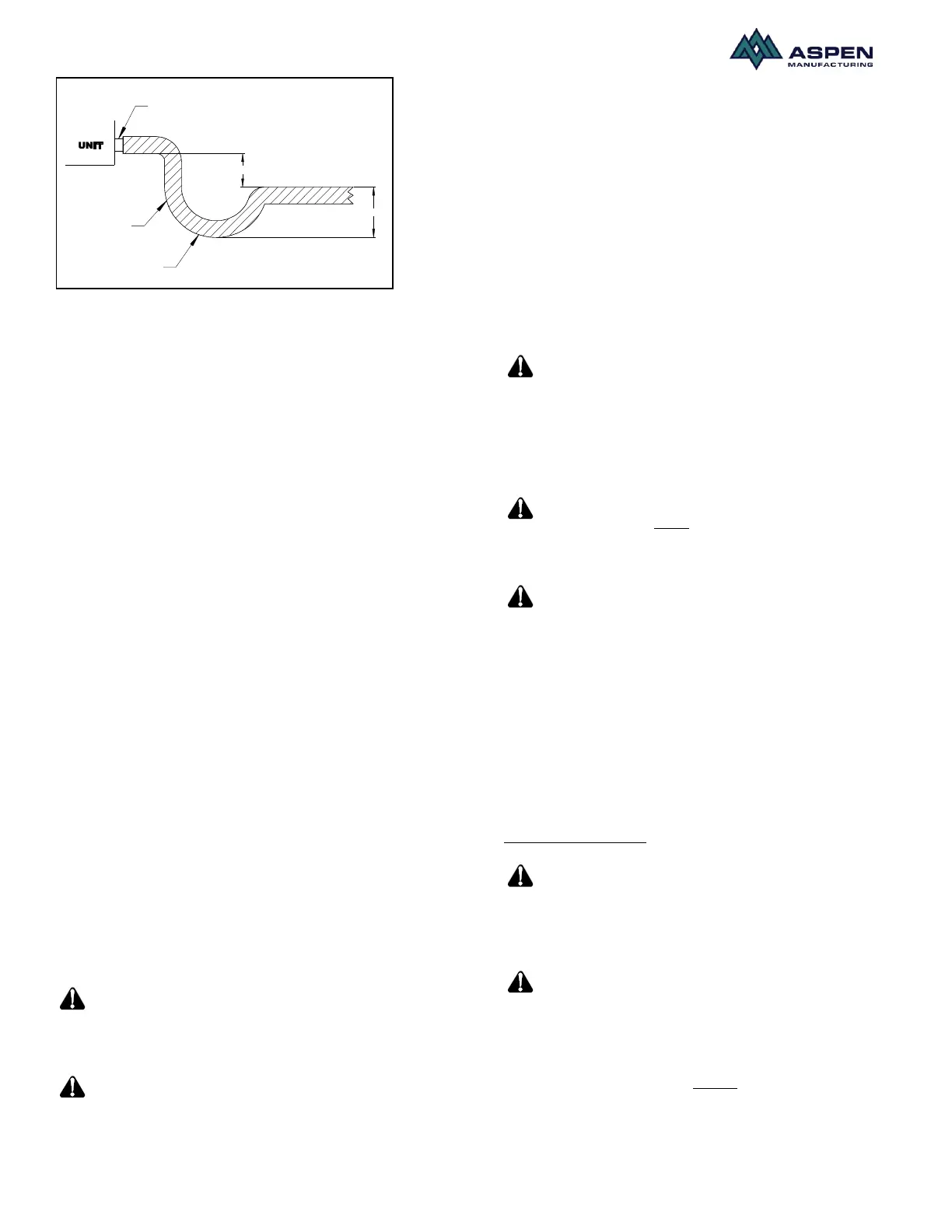

2" MINIMUM

3" MINIMUM

FLEXIBLE

TUBING-HOSE

OR PIPE

A POSITIVE

LIQUID SEAL IS

REQUIRED

DRAIN

CONNECTION

Figure.1. Typical drain line trap set up

Ductwork

Duct systems should be installed in accordance with

standards for air-conditioning systems, National Fire

Protection Association Pamphlet No. 90A or 90B. They

should be sized in accordance with National

Environmental System Contractors Association Manual

K, or whichever is applicable.

On any job, non-flammable flexible collars should be

used for the return air and discharge connections to

prevent transmission of vibration. Although these units

have been specially designed for quiet vibration-free

operation, air ducts can act as soundboards can, if

poorly installed, amplify the slightest vibration to the

annoyance level.

All main supply and return air drops should be properly

size as determined by the designer of the duct system

and should not necessarily be the size of the duct flange

openings of the unit.

When installing a central air return grille in or near the

living space, it is advisable to design the ductwork so

that the grille is not in direct line with the opening in the

unit. One or two elbows and acoustical duct liner will

also assure a quieter installation and system.

It is recommended that wherever supply and return air

sheet metal duct pass through unconditioned areas, they

be insulated to prevent excessive heat loss during

heating operation. When applied in conjunction with

summer air conditioning, sheet metal duct routed

through unconditioned areas should be insulated and

have an outside vapor barrier to prevent formation of

condensation.

Installation

Ensure that the unit is adequately

sized. The tonnage of the outdoor unit should never

exceed the tonnage of this unit.

The coil was manufactured with

dry nitrogen pre-charge. Release the pressure through

the Schrader valve test port prior to installation. If

holding pressure is not present, return coil to distributor

for exchange.

Clean coil fins with degreasing agent or mild detergent

and rinse fins clean prior to installation.

All connection joints should be burr-free and clean. Not

removing the burr and cleaning may increase chances of

a leak. It is recommended to use a pipe cutter to remove

the spun closed end of the suction line.

To avoid damage to grommets (where present), remove

these prior to brazing by sliding over the lines. Use a

quenching cloth or allow the lines to cool before

reinstalling the grommets.

Prior to connecting the water

(hydronic) coil, make sure that the hot water supply is

turned on. Water from the heater could be extremely hot

and might result in burns and other personal injusry

along with equipment damage. Ensure that proper saftey

gear is being used prior to making connections.

Only lead free solder should be

used to connect water (hydronic) coil to the hot water

source.

Some Aspen coils may include a

Schrader valve on the suction manifold. Ensure that the

Schrader valve and valve core (where present) are

protected from heat to prevent leakage.

Metering Device

Aspen coils are available with two kinds of metering

devices a) flowrator or b) TXV. Instructions below are

separated in sections according to the metering device.

Ensure that the applicable section is thoroughly read and

understood.

Flowrator Coils:

Use Piston sizes recommended by

the outdoor unit manufacturer whenever possible. The

piston should be sized according to the capacity of the

outdoor unit.

Failure to install the proper piston

can lead to poor system performance and possible

compressor damage.

During some installations a piston change may be

required. If so the installer MUST change the piston. As

stated earlier, use piston sizes recommended by the

outdoor unit manufacturer. If a sizing chart is not

available, use the piston size chart provided below to

Loading...

Loading...