IO-123075 Effective 12-01-11

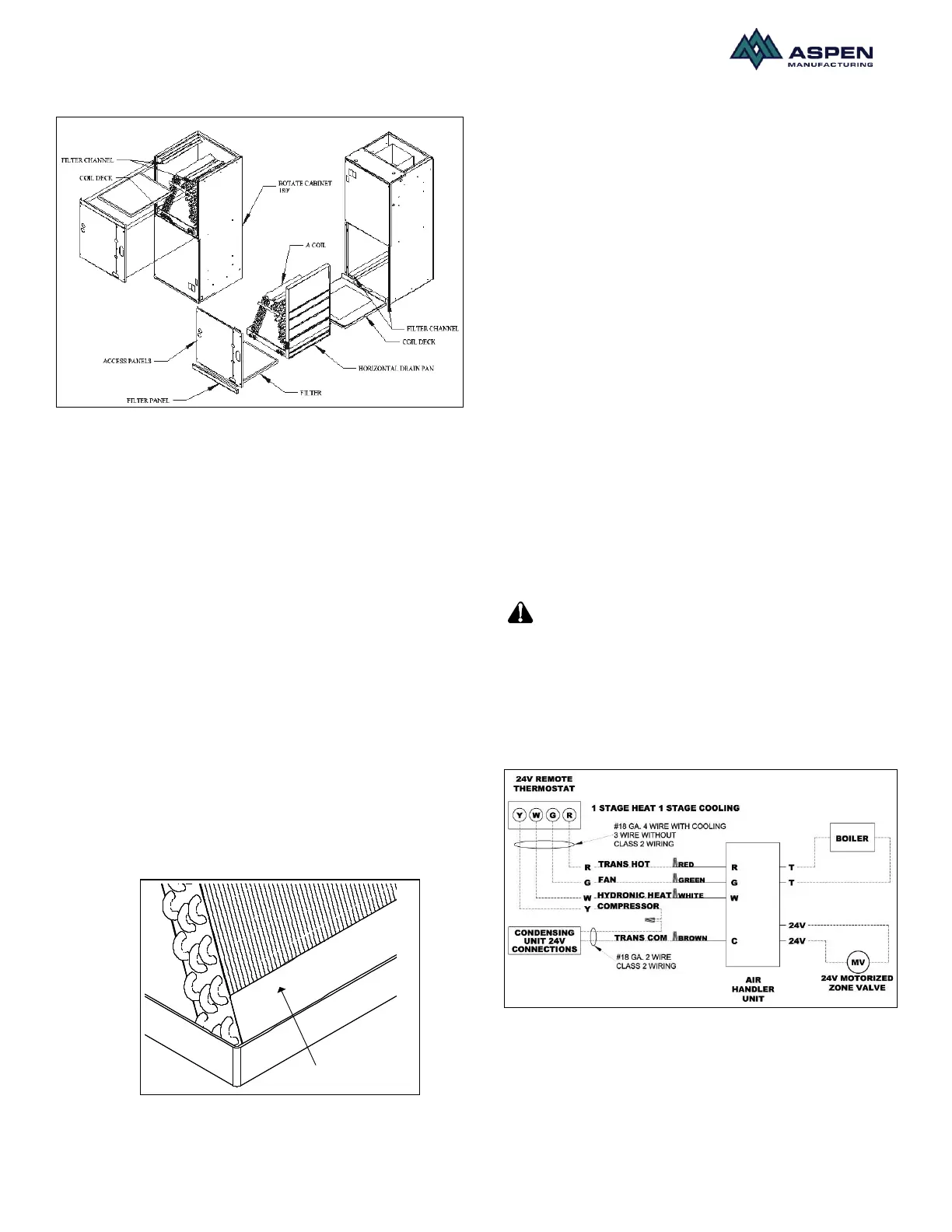

Counter Flow Installation

Fig.8. Air Handler parts and changes for Counter flow

• Before positioning the Air Handler in the counter

flow position, remove lower access panels, filter

panel and filter.

• Remove the A-Coil assembly with the horizontal

drain pan; discard the horizontal drain pan (not

required for counter flow application).

• Rotate the Air Handler 180° to the counter flow

position.

• Remove the coil deck and filter channel, rotate

the filter channels 180° and re-attach in the

same location they were removed from.

• Rotate the coil deck 180° and re-attach in the

holes near the center of the cabinet (screws not

provided).

• Slide the A-coil assembly into the cabinet on the

coil deck (without the horizontal drain pan).

Note: Push the coil pan assembly all the way to

the rear of the cabinet until it locks under the

bracket in the rear.

• Place the 3” x 16” counter flow plates at the

outside bottom of the coil as shown in FIG. 9.

• Replace the access panels and filter panel.

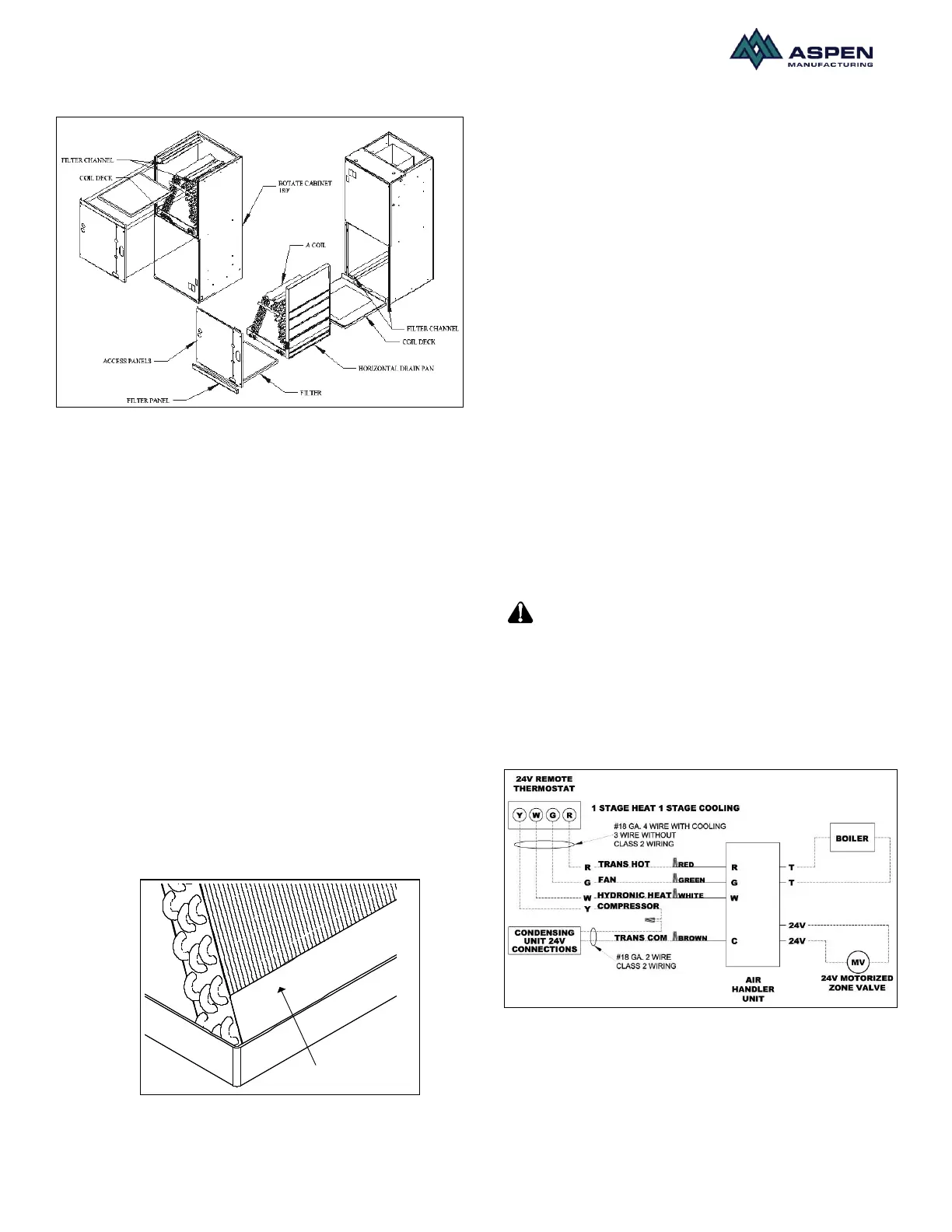

Fig.9. Position of plates required in counter flow

Electrical Installation

These units are designed for single or three phase 120

volts, 60 Hz power supply. Wire selection and wiring

must be in accordance with the National Electric Code

and/or local codes. Unit terminals are designed to

accommodate copper and aluminum wirings. If

aluminum wiring is used; please observe special

precautions relative to sizing, wire connections and

corrosion protection.

Fig.10 shows the typical electrical connections required

for A/C only and heat pump applications.

The unit ships with a micro-processor based board

which controls the electrical functioning of the unit. An

inspection of the controls is recommended prior to start-

up.

Fig.11 provides a schematic of the control board present

in the unit. The units ship from the factory with the

aquastat jumper in the OFF position (right two pins) and

the heating selector in the HW position (right two pins). If

an aquastat is used in the application; the jumper should

be changed to ON position (left two pins).

Note: Terminals T and N located on the top right side

of the board are not intended for field use and should be

left unconnected.

The aquastat (AQ) jumper must be

in the OFF position at all times; except for when an

aquastat is used in the application. If the jumper is

moved to the ON position without installing an aquastat

the blower will not be energized.

When an aquastat is present, the blower will be

energized at the aquastat temperature settings.

Fig 10. Electric connections

On units shipped from factory with a pump installed the

pump will be energized on call for heat.

In units that were shipped without factory installed

pumps, two black wires should be connected to the

boiler terminals T T. In applications where a boiler is

Loading...

Loading...