used to provide the hot water supply, these wires shouId

be connected to the boiler. Terminals T T are normally

open dry contacts.

In applications where a valve is used to regulate hot

water supply, the two black wires located on the T T

terminals should be removed and placed on the two

terminals reading “VALVE”. The open ends of the wires

should be connected to the valve according to local

requirments and instructions of the valve manufacturer.

On call for heat, 24V will be sent to the field installed

valve or pump relay.

On call for heat water will circulate through the water

(hydronic) coilfor 60 secs prior to energizing the blower.

After the thermostat is satisfied, the blower will continue

to stay energized for a minimum of 30 sec. This helps

maximize heating efficiency.

The freeze protection sensor is connected to the FP and

R terminals. These are normally open and will close

when the sensor sees 40ºF. The pump stays ON for a

minimum of 30 sec.

The board has an built-in timer which circulates hot

water 6 times a day for 60 sec each time to prevent the

coil from freezing.

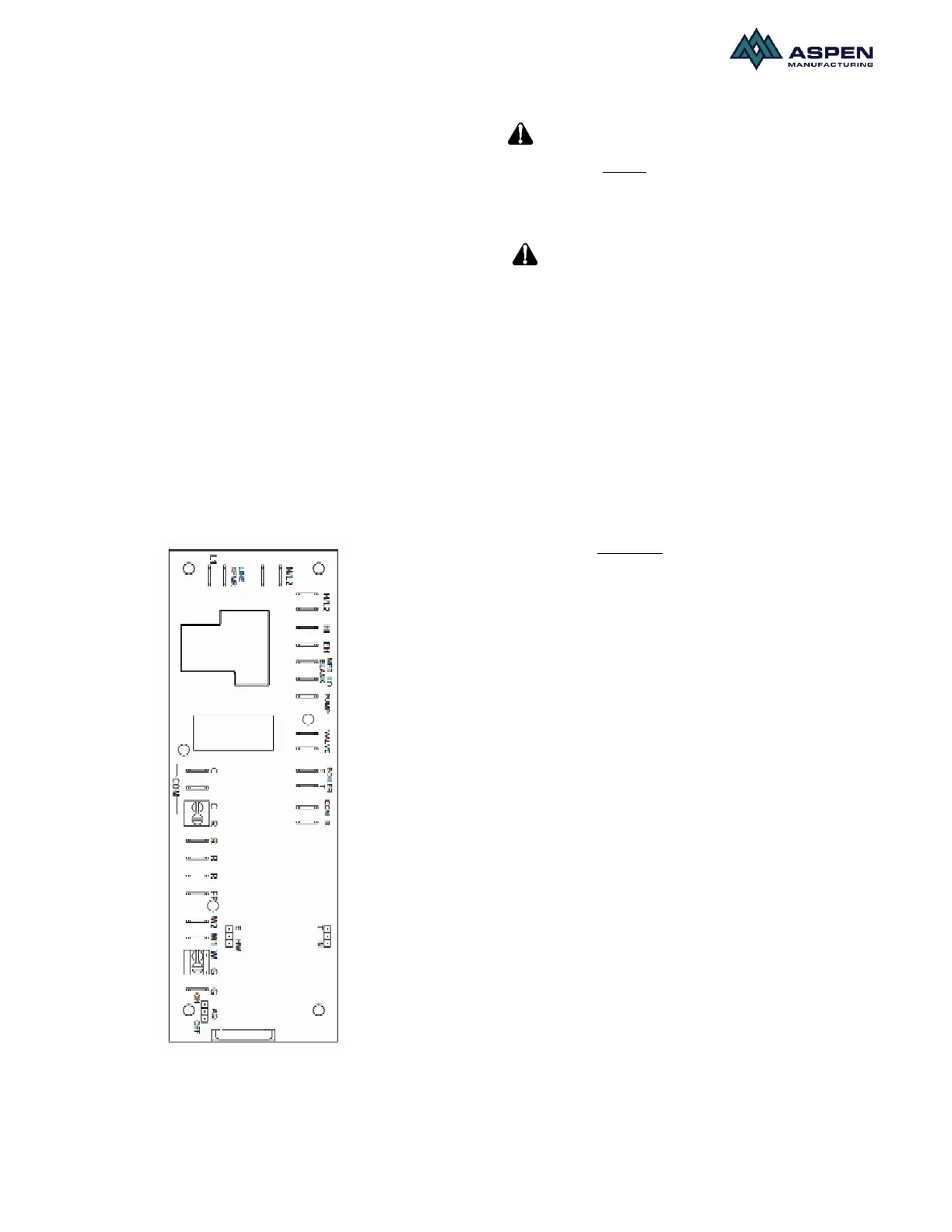

Fig.10. Micro-processor control board

Start up

Hot water flowing to the coil

should be in the range of 120º - 180º F. Water at these

temperatures can cause first-degree burns. Use of

proper saftey gear while installing or servicing the

equipment is strongly recommended, as is installation of

a water-tempering valve (for water temperatures of

above 140ºF) to supply lower temperature water to

fixtures in the house. N170L series or equivalent should

be used.

Connect the hydronic coil to the water heater system as

shown in Fig 11. Use flexible piping and insulate all

pipes. Plumbing must be in compliance with state or

local codes (Code CMR248 in Massachusetts). The

units for hydronic heat have different top and heater box

configurations. This configuration is not suitable for

electric heat. DO NOT try to install a hydronic heater in a

unit not equipped for it. Verify connections: hot water to

“in” and cold water to “out”. 7/8” ODstubs are provided

for plumbing connections. Bleed the air flow system

through the bleeder port or optional valve.

Purging The System

1) Open air vent and allow water heater to fill with

water. Close air vent when water heater is full and

all air has been purged.

2) Ignite water heater. Set thermostat on water heater

to 140 degrees.

3) Close the valve on the hot water supply from the

water heater ("A") and open the valve on the cold-

water return to the water heater ("B"). Then open the

air vent in the fan coil. Use a bucket or hose to

discard water during purging process at air bleed

valve. Purge air completely from line.

4) Once air is purged, close return valve ("B") and open

supply valve ("A"). Purge the coil and lines of air

completely.

5) After air is purged from the system and filled with

water, open the return valve ("B") and the supply

valve ("A"). Then close the air vent in the fan coil.

6) Apply power to the fan coil and set the room

thermostat on heat. Raise the temperature setting to

activate the circulating pump

7) Check the pump to ensure proper operation. The

water inlet of the unit should be hot if the water

temperature in the water heater has reached the set

point. If water is not being circulated through the coil

but the pump is running, then open the air bleed

valve in the unit and purge any air left in the system.

Loading...

Loading...