0

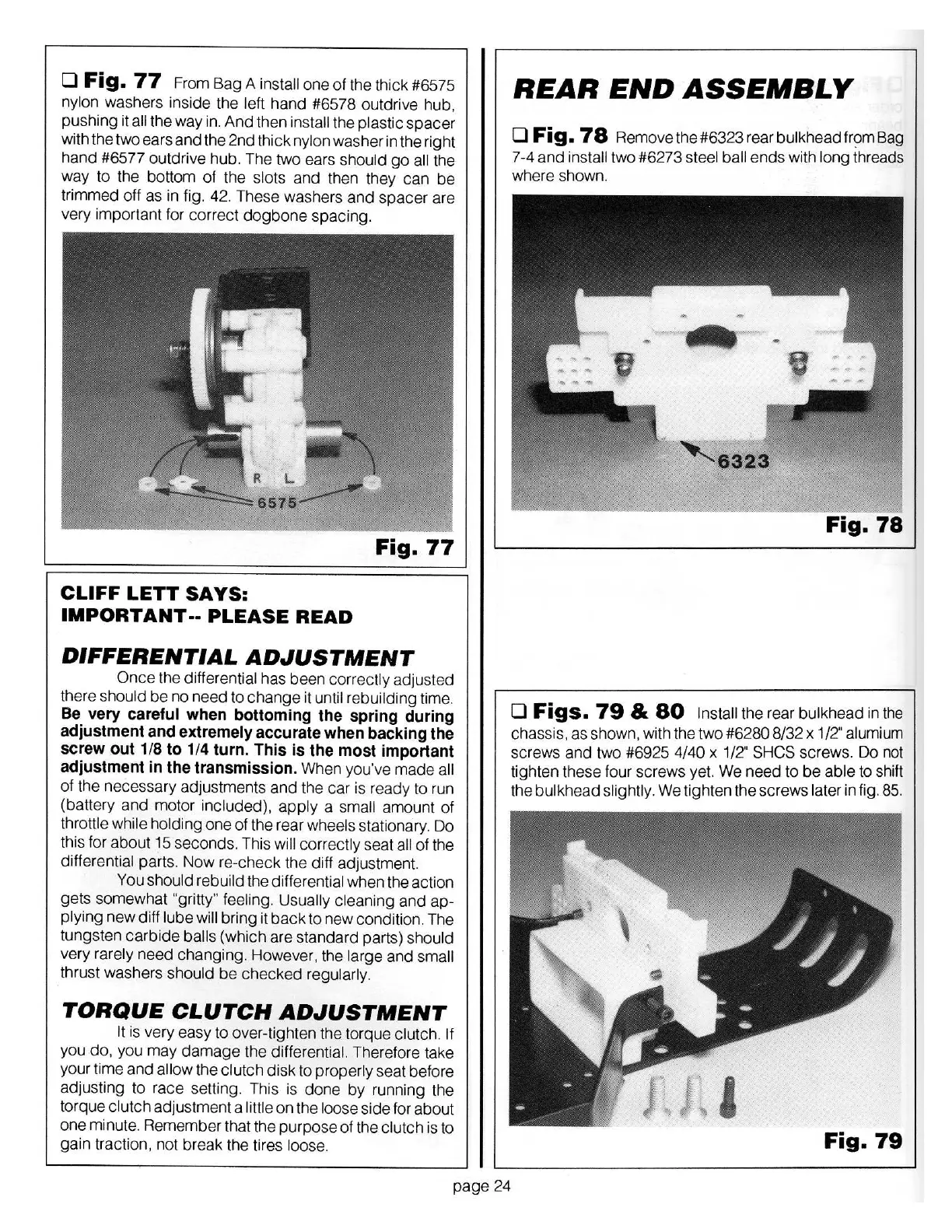

Fig.

77

From

Bag

A install one

of

the thick #6575

nylon washers inside the left hand #6578 outdrive hub,

pushing it all the way in.

And

then install the plastic spacer

with the two ears and the 2nd thick nylon washer in the right

hand #6577 outdrive hub. The two ears should

go

all the

way to the bottom

of

the slots and then they can be

trimmed

off

as in fig.

42

. These washers

and

spacer

are

very important for correct

dogbane

spacing.

Fig.

77

CLIFF

LETT

SAYS:

IMPORTANT··

PLEASE

READ

DIFFERENTIAL

ADJUSTMENT

Once the differential has been correctly adjusted

there should

be

no need to change it until rebuilding time.

Be

very careful when bottoming the spring during

adjustment and extremely accurate when backing the

screw out 1/8

to

1/4 turn. This is the most important

adjustment in the transmission.

When you've made all

of

the necessary adjustments

and

the

car

is ready to run

(battery and motor included),

apply

a small amount of

throttle while holding one

of

the rear wheels stationary. Do

this for about 15 seconds. This will correctly seat all of the

differential parts. Now re-check the diff adjustment.

You should rebuild the differential when the action

gets somewhat "gritty" feeling. Usually cleaning

and

ap-

plying

new

diff lube will bring it

back

to new condition. The

tungsten

carbide

balls (which are standard parts) should

very rarely need changing. However, the large and small

thrust washers should be checked regularly.

TORQUE

CLUTCH

ADJUSTMENT

It is very easy

to

over-tighten the torque clutch. If

you

do

, you may

damage

the differential. Therefore take

your time and allow the clutch

disk

to properly seat before

adjusting to race setting. This is done

by

running the

torque clutch adjustment a little on the loose si

de

for about

one minute. Remember that the purpose

of

the clutch is to

gain traction, not break the tires loose.

REAR

END

ASSEMBLY

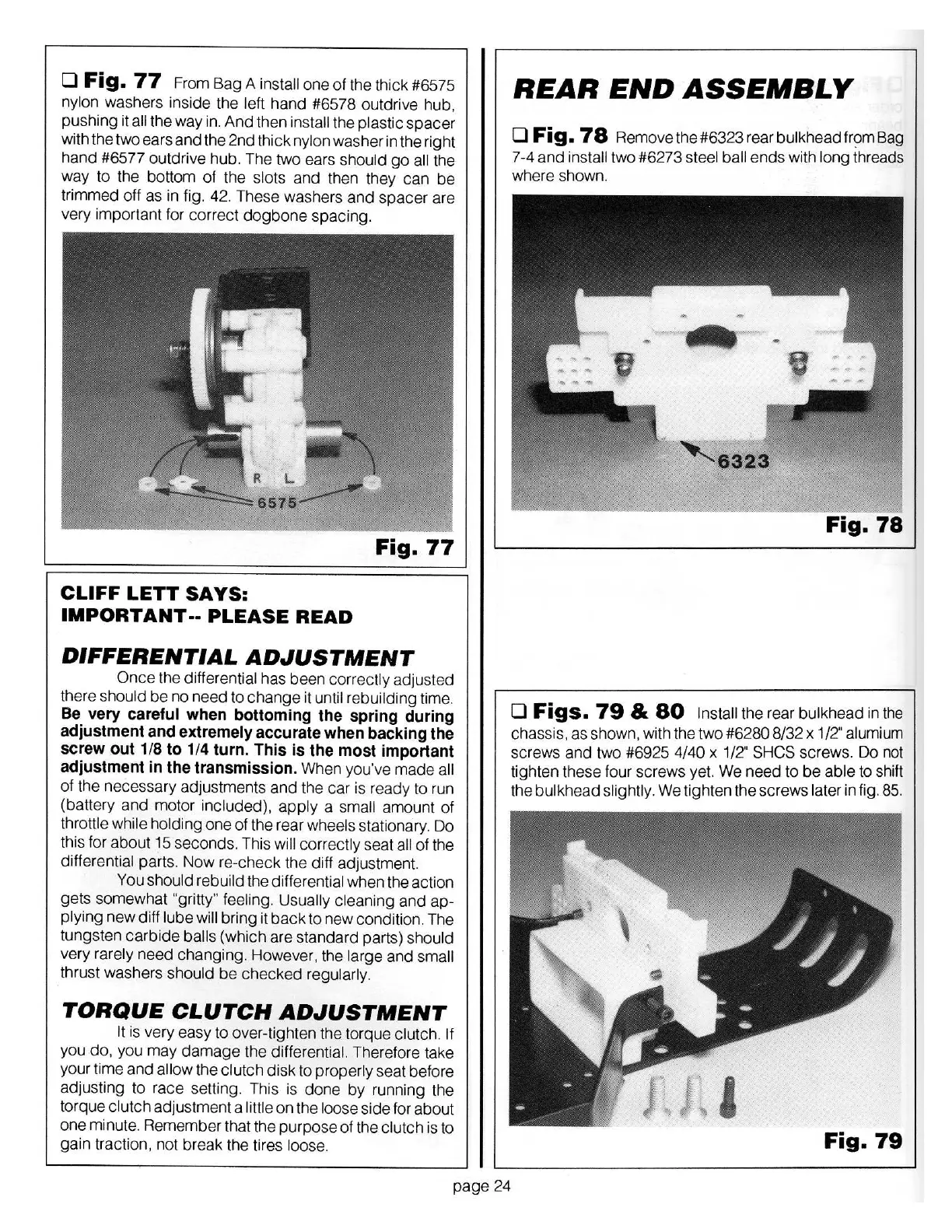

0

Fig.

78

Removethe#6323rearbulkheadfr~mBag

7-4

and

install two #6273 steel ball ends with long threads

where shown.

-

-

""""""'

> •

v

Fig.

78

0

Figs.

79

&

80

Install the rear bulkhead in the

chassis, as shown, with the two #6280 8/32 x 1/2" alumium

screws and two #6925 4/40 x 1/2" SHCS screws. Do

not

tighten these four screws yet. We need to

be

able to shift

the bulkhead slightly. We tighten the screws later in fig. 85.

Fig.

79

page

24

Loading...

Loading...