78

Wear Parts

Feed Disc

On a rotor, the center bolt

accomplishes this.

However, casting tolerances

prevent a close tolerance

t, and serious accelerator

vibration can occur if the feed

disc is not centered.

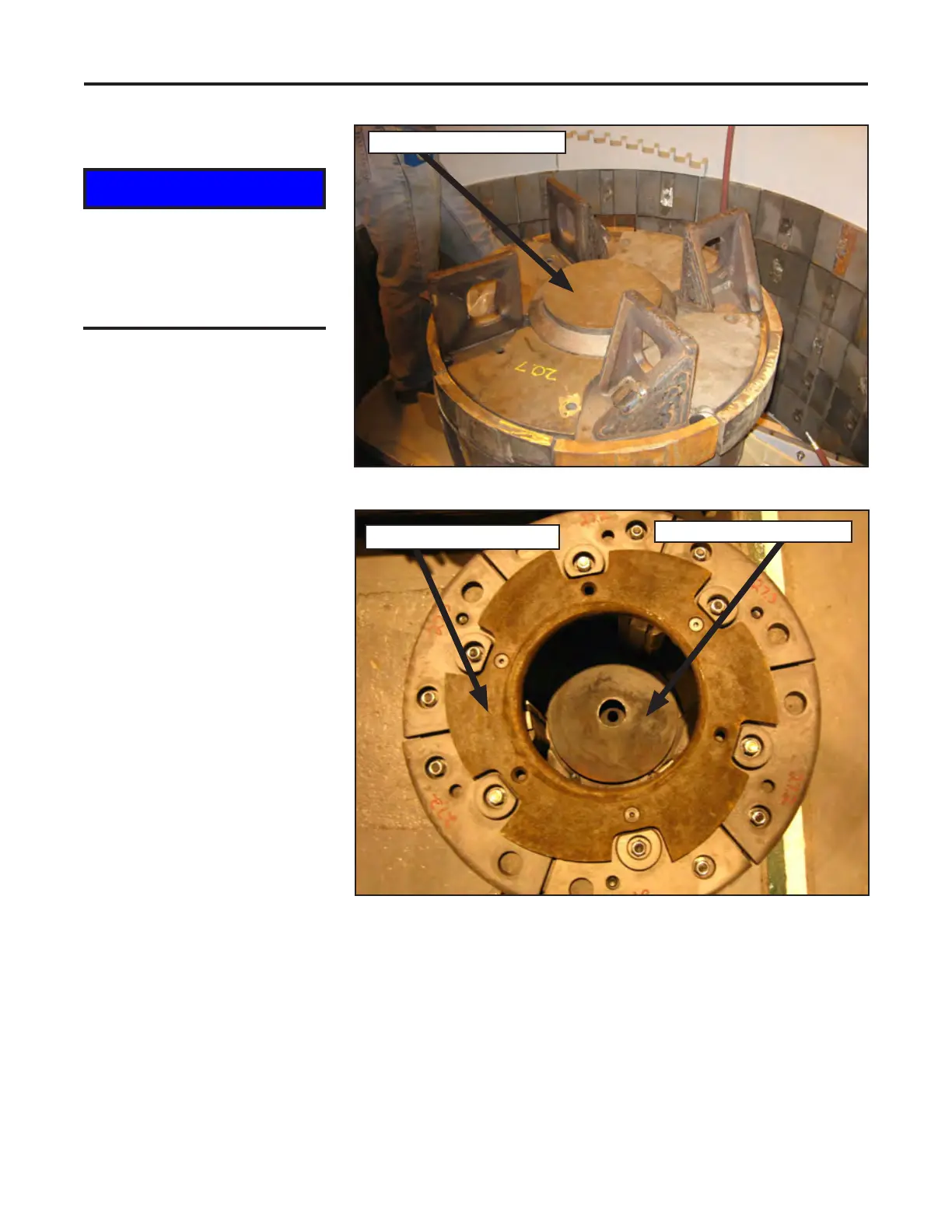

Feed Disc - Rotor Assembly

Feeddisc-upto107lbs.

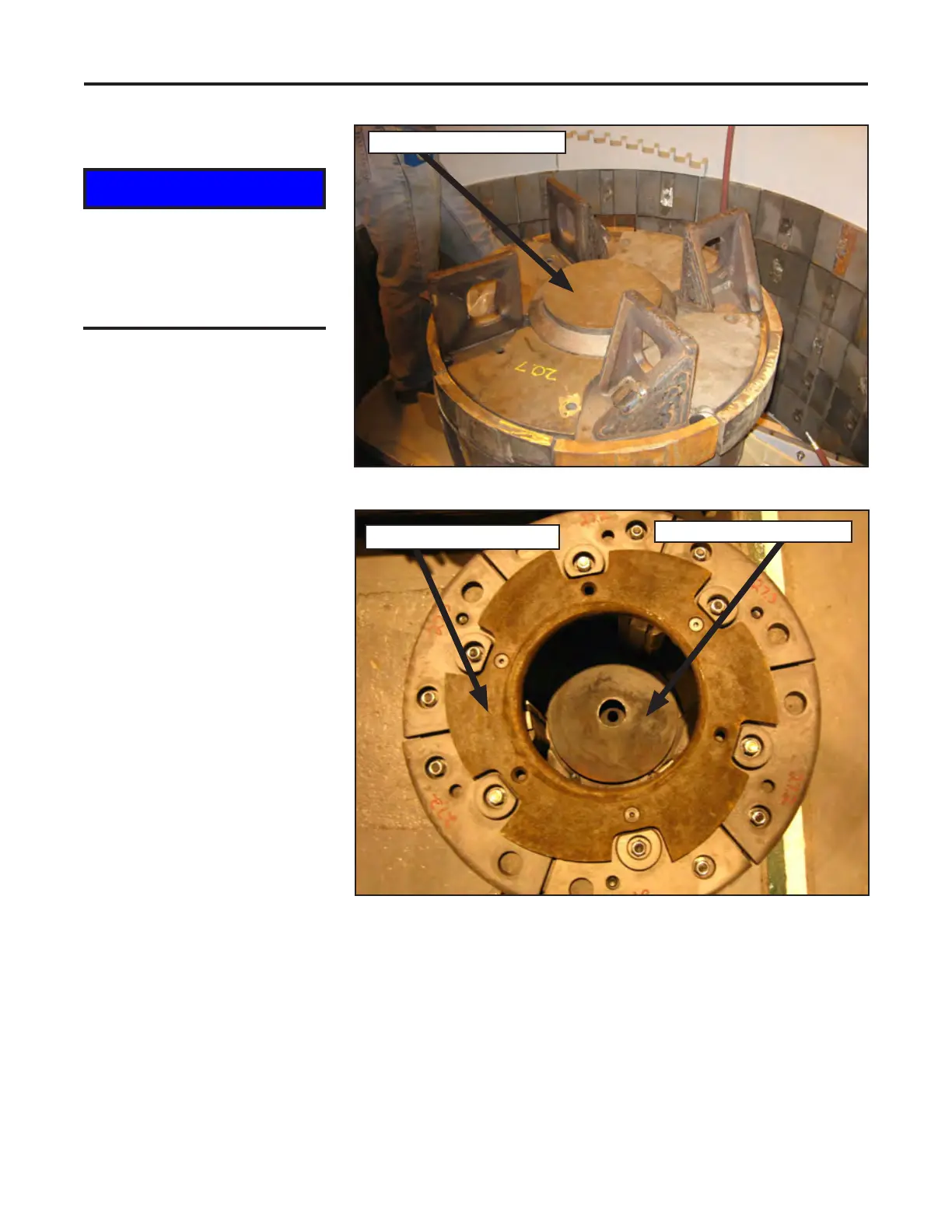

Feed Disc - Table Assembly

Feeddisc-upto150lbs.

The feed disc should never be

allowed to wear completely

through as serious damage

can be caused to crusher

components.

Feed disc wear is evident by a

rounding off of its outer edge

immediately in front of the

impeller shoe. While wear is

normal, rotating the feed disc

approximately 30 degrees

clockwise will present a fresh

corner. Properly maintained,

the feed disc allows for optimum

feed distribution and optimum

material trajectory to the anvils.

Improperly maintained, a worn

feed desk can result in:

• “Slotting” of the impeller

shoes or carbides.

• Accelerated wear on at

table liners.

• A poor wear pattern

• Overall reduced crushing

efciency.

When replacing a feed disc

make sure it is centered on the

accelerator.

On a table, the bevel on

the impeller shoes helps

accomplish this.

NOTICE

Feedring-upto110lbs.

When the feed disc is replaced,

torque the center bolt to 199

ft.lbs. (1500 models) or 480

ft.lbs. (2500 and 4500 models).

Loading...

Loading...