C

1

2

3

4

ATAG Heating Technology advises on an interim service inspection with a flue gas

analyser. A full strip down service is recommended at regular intervals or where

analyser readings are not within correct safety standards.

Required tools:

• Cross head screwdriver

• T-handle key set with 3 bits (hex key 4mm, hex key 5mm and cross head PZ2)

• Open end wrench 8mm

Interim Service

For reasons of safety and economy, it is recommended that the boiler is serviced

annually. Servicing must be performed by a competent person in accordance with

BS 7967.

After servicing, complete the relevant Service Interval Record section of

the Benchmark Checklist located on the inside back page of this document.

In order to perform maintenance, the following actions have to be taken:

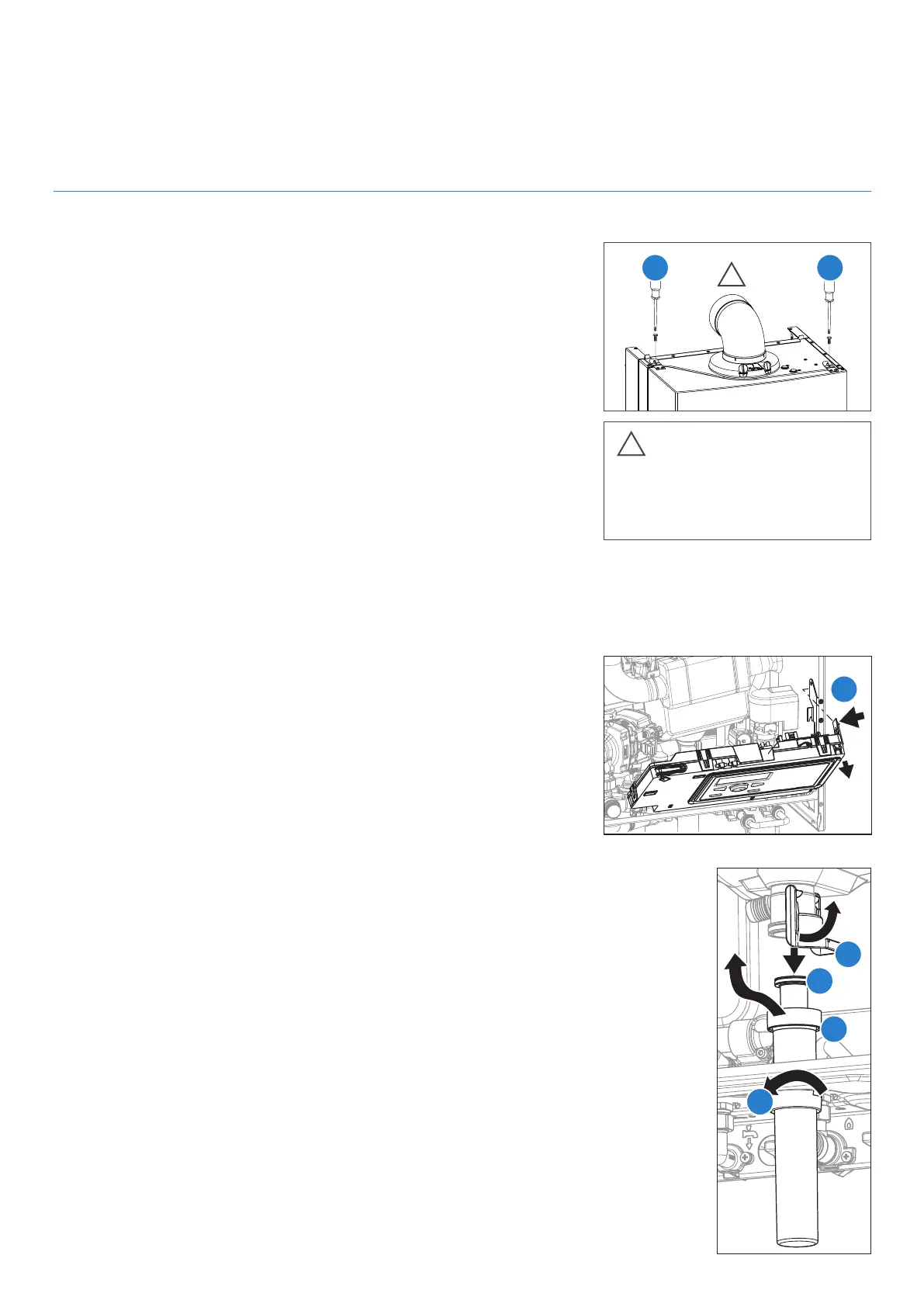

• Switch o the electrical power to the boiler

• Remove the screws from the 2 fasteners (A) and (B)

• Unlock the fasteners (A) and (B) and remove the cover in a forward motion

Air box/cover

The cover also doubles as air box:

• Clean the air box/cover with a cloth and a non-abrasive cleaner

Siphon

The degree of pollution residue in the siphon is an important indication for the need of

maintenance

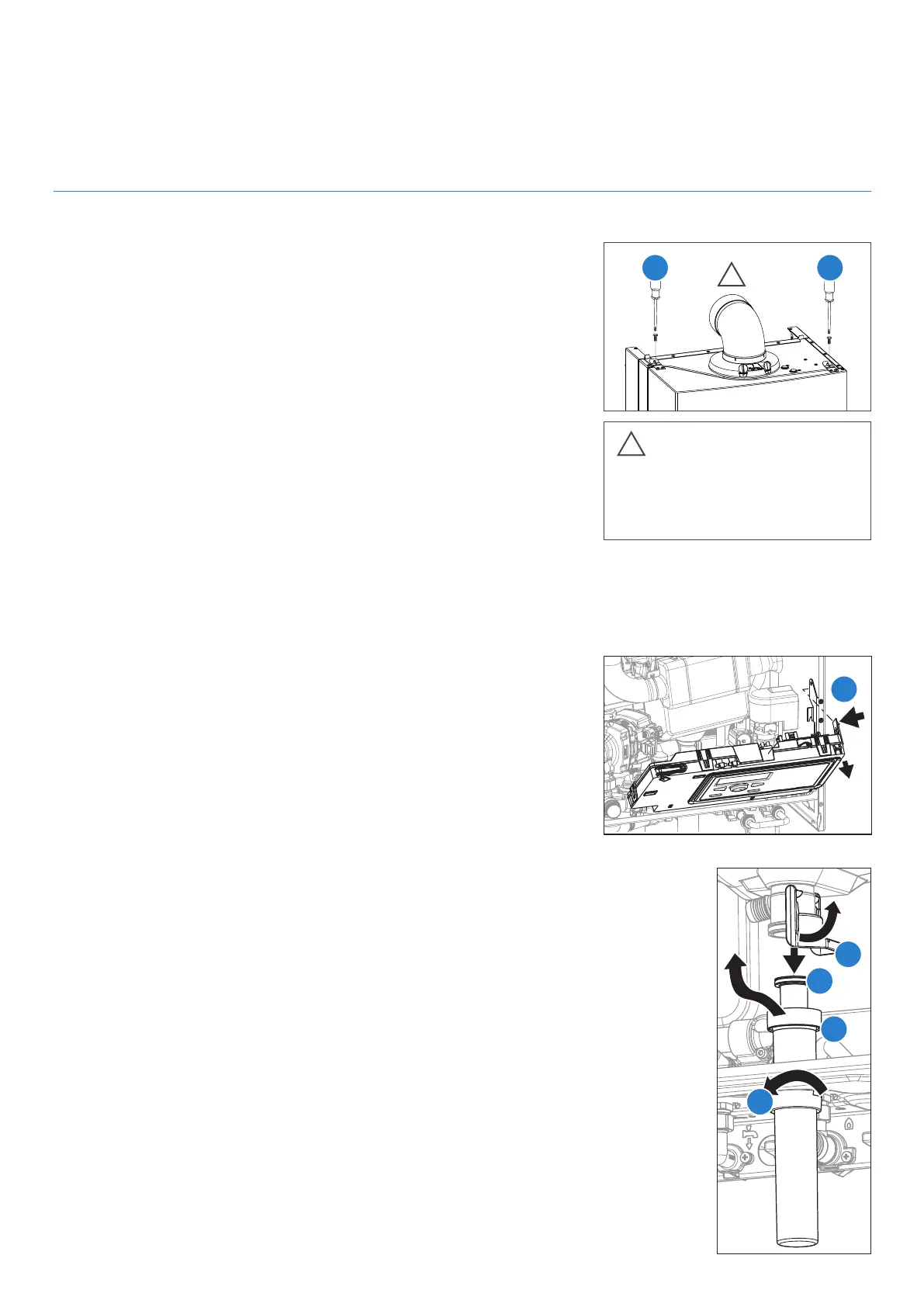

• Turn the control unit forwards by moving the handle (C) slightly to the left

• Turn/pull the sealing ring (1) downwards

• Turn the siphon securing clip (2) anti-clockwise

• Pull the siphon cup (3) and siphon pipe (4) out of the heat exchanger

• Take the siphon cup and pipe out of the boiler by moving it

downwards or turn it in forward motion upwards along the heat

exchanger

• Clean the parts by rinsing them with water

• Check the O-ring of the siphon cup and replace it if necessary

• Grease the O-ring again with acid-free O-ring grease to simplify

the reassembly

Reassembly takes place in reverse order

• Fill the siphon with 150 ml of water

• If a leakage has occurred to the siphon, replace the entire siphon

Routine servicing

NOTE ALWAYS REFIT AND TURN THE

2 SCREWS TIGHT IN THE FASTENERS

A AND B.

A B

!

!

56

Loading...

Loading...