12

O&M Manual

Rev-N (4/21)

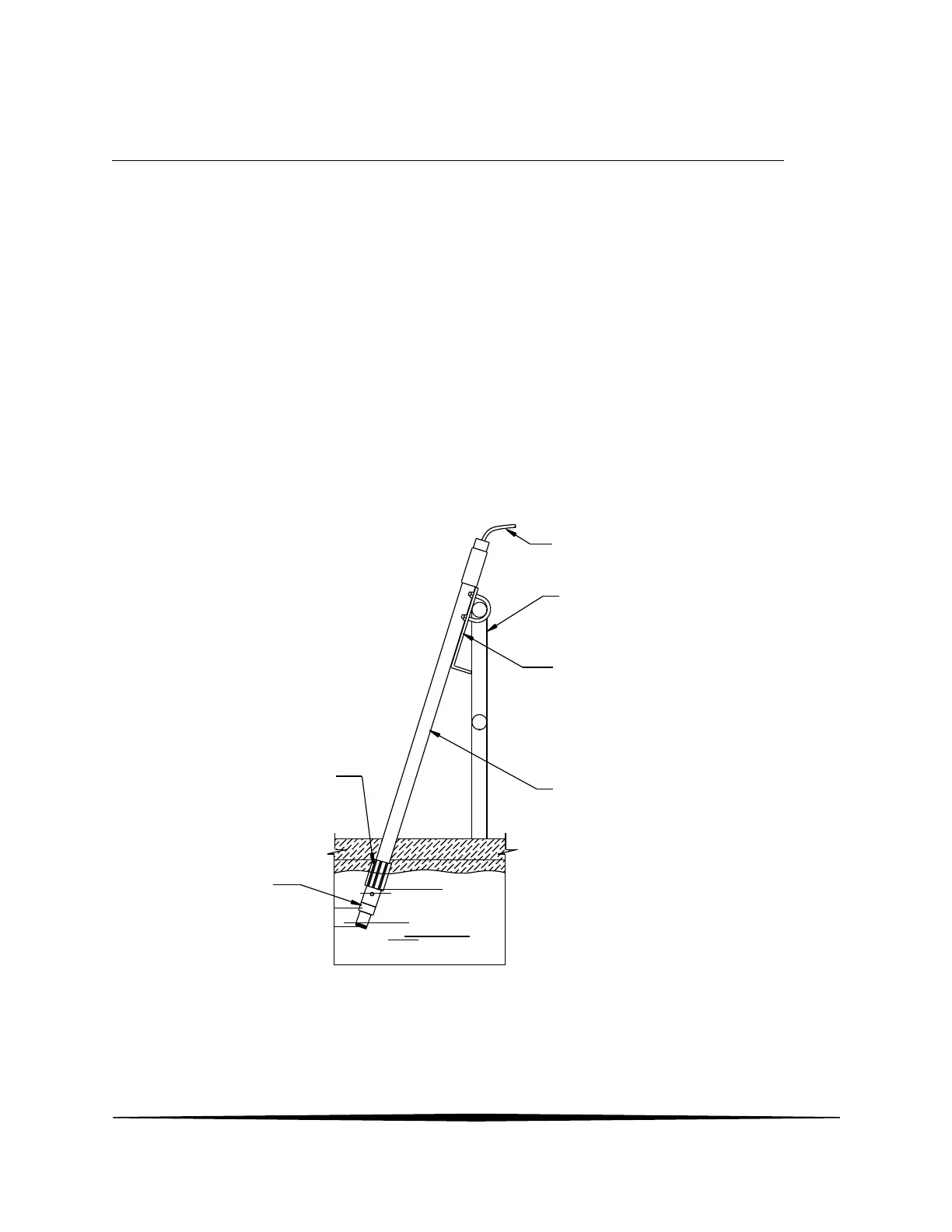

Part 3 – Sensor Mounting

3.1 General

Select a location within the maximum sensor cable length for mounting of the sensor. Locating

the sensor within 25 ft. of the transmitter is generally preferred for ease of operation and

calibration.

3.2 Submersion Mounting

Most applications for D.O. monitoring are done using a submersible sensor. This method can be

used where flow is reasonably constant, and hydraulic head does not vary more than about 10

feet. Oxygen sensors can never be used in completely stagnant conditions. A flow velocity of at

least 0.3 feet per second is normally required for measurement.

Submersible sensors are mounted to a 1" pipe using a standard 1" PVC thread by thread pipe

coupling. The mounting pipe can be secured to standard 1½” or 2” pipe rail using a mounting

bracket kit available from ATI (part number 00-0628) as shown in Figure 6 - Submersible Sensor

Mounting.

SENSOR CABLE

2" HANDRAIL

1" ALUMINUM CONDUIT, THREADED1" T x T PVC COUPLING

ONE END OR 1" SCHED 80 PVC PIPE

LENGTH AS REQUIRED

(SUPPLIED BY CUSTOMER)

SWIVEL MOUNTING BRACKET WITH

HARDWARE, SUPPLIED BY ATI

SUPPLIED BY ATI

SENSOR, TYPICAL

2 - 3 FT. SUBMERGENCE

Figure 6 - Submersible Sensor Mounting

Loading...

Loading...