Industrial Air Division

2920 5997 03

14

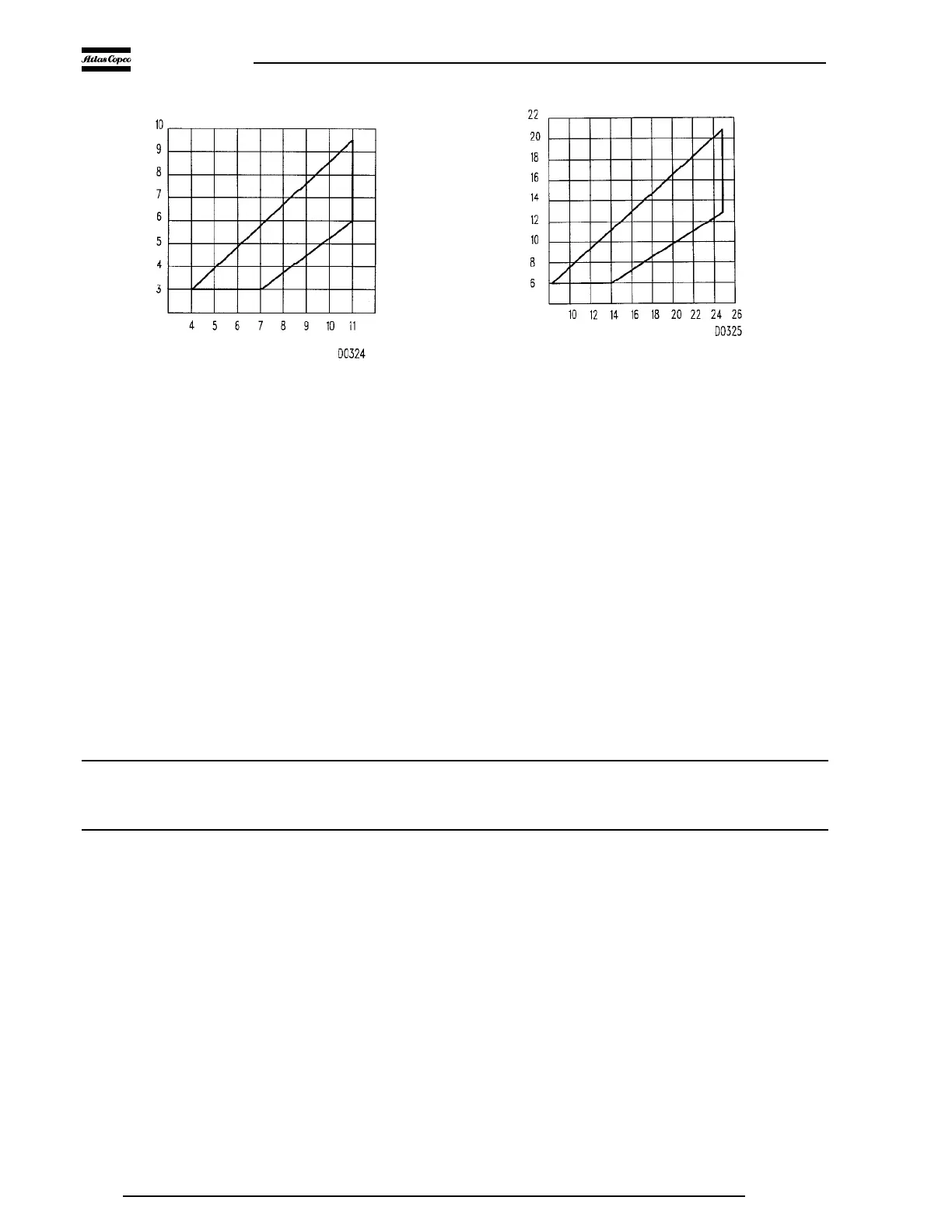

Switching-on pressure

bar(e)

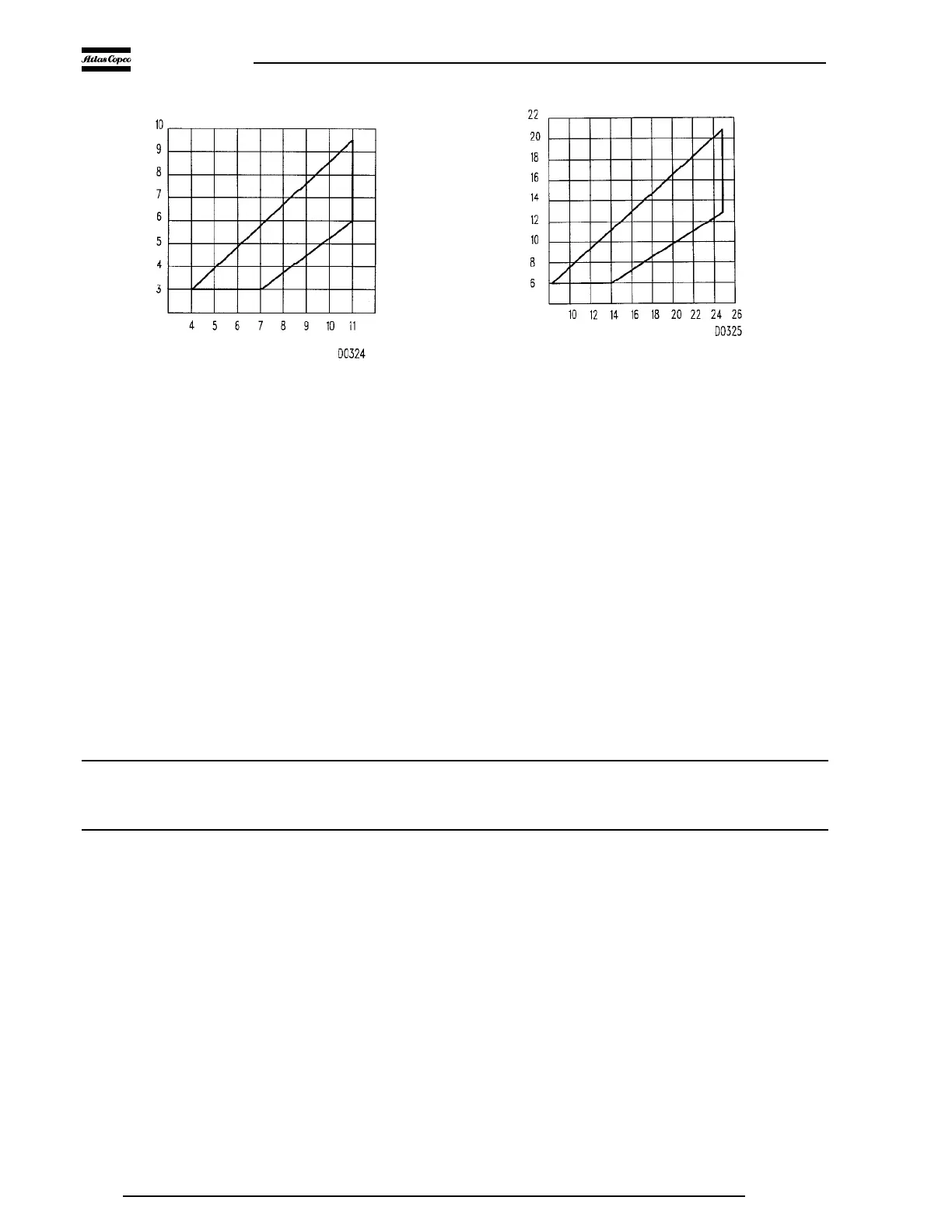

Switching-on pressure

bar(e)

LE7 up to -12

LE7N/9N

LT7 up to -12

Switching-off pressure → bar(e) Switching-off pressure → bar(e)

Figs. 9. Diagrams, pressure differential adjustment range

Explanation about the table below:

- Conditions of the unit, always preceded by a number, are

printed in bold.

- Each possible fault is followed by its related suggested

remedy and both are preceded by the same letter.

1. Insufficient air pressure

a. Air leak(s)

a. Check and correct as necessary

b. Air filter choked

b. Replace filter

c. Air pressure switch incorrectly set

c. Adjust switch

d. Air consumption exceeds maximum output of compressor

d. Check equipment connected

e. Damaged valve(s)

e. Inspect valves and replace parts where necessary

f. Pressure gauge defective

f. Check and replace, if necessary

g. 1) Release valve of air pressure switch not airtight during

loading

g. Check mechanism of valve. If necessary, replace valve

h. 2) Unloader plunger jammed or unloader valve or spring broken

h. Inspect unloader and replace parts where necessary

i. 2) Solenoid valve out of order

i. Remove and check valve. Replace if necessary

2. Unit does not speed up

a. Voltage drop at motor terminals

a. Consult power supplier. Change to larger cross-section

cable, if necessary

b. 1) Pressure release valve of air pressure switch malfunctioning

b. Check operation of valve, replace if necessary

c. 2) Unloader plunger jammed

c. See 1h

d. 2) Solenoid valve out of order

5.6 Relief valve (27-Figs. 1) (only LT)

The relief valve protects the LP side of the compressor. It is fitted

on the air inlet pulsation damper of the HP cylinder. The valve

must be tested yearly.

Remove the relief valve and fit a 3/8" B.S.P. plug instead. Remove

the safety valve from the air receiver and replace it by the relief

valve. The latter can then be tested at increasing air receiver

pressure after the compressor has been started with open air outlet

valve. If the valve has not opened at the pressure specified in

section 7, it must be replaced by a new one. Reinstall the valves in

their respective places after testing.

6 Problem solving

Loading...

Loading...