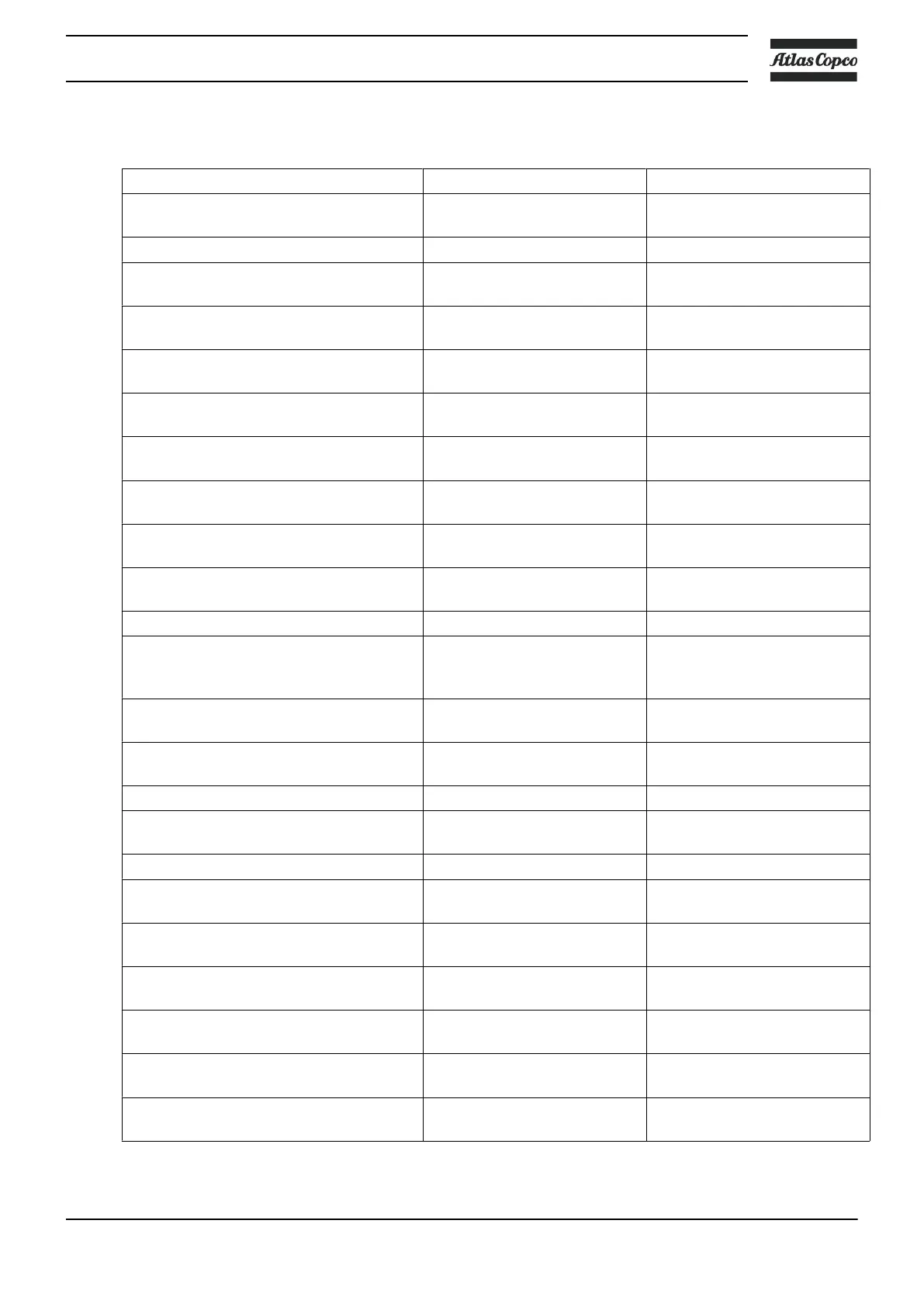

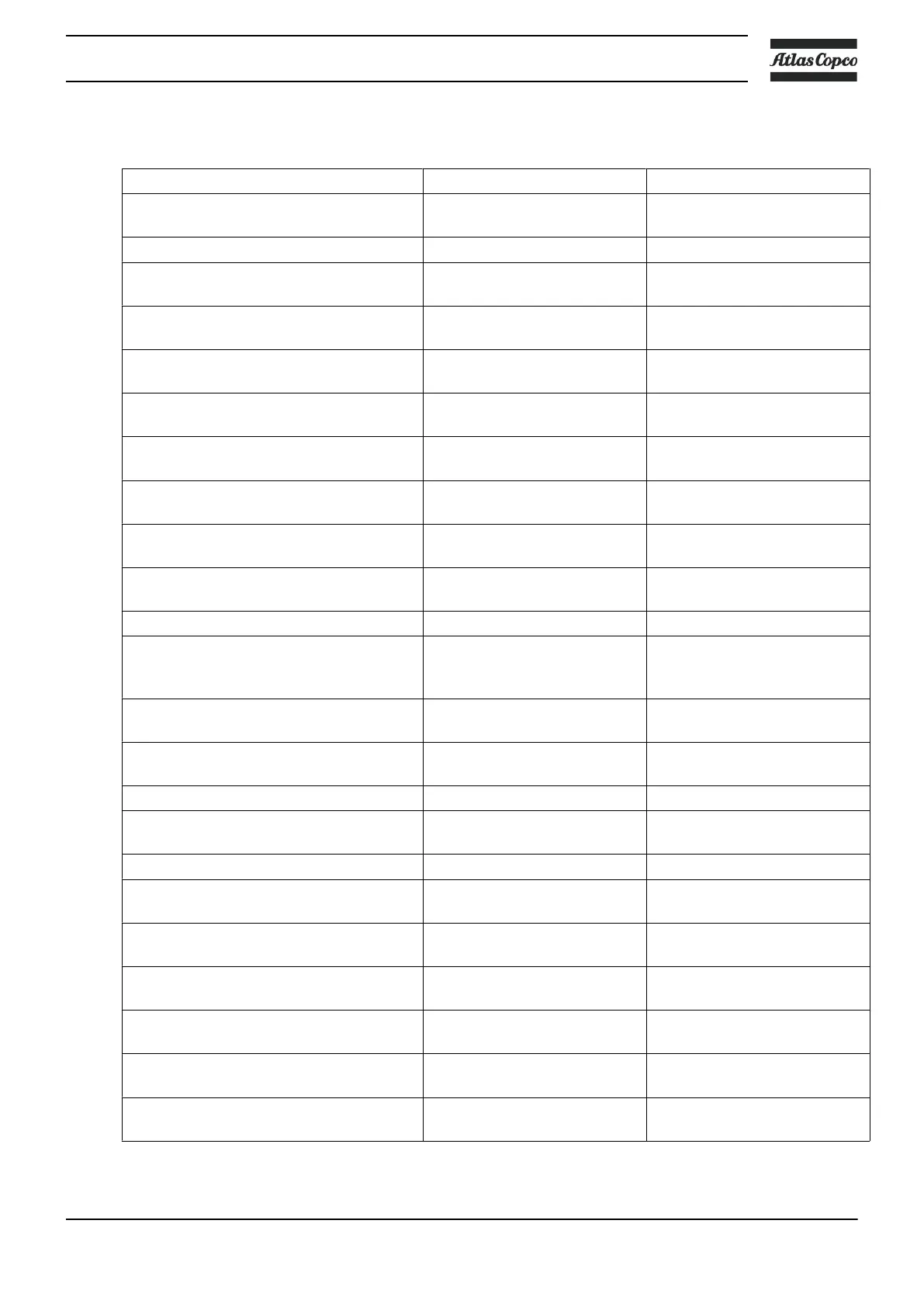

7 Problem solving

Condition Fault Remedy

Insufficient air pressure Air leak Check and correct as

necessary

Air filter choked Replace filter

Air pressure switch incorrectly

set

Adjust switch

Air consumption exceeds

maximum output of compressor

Check equipment connected

Damaged valve Inspect valves and replace

parts where necessary

Unloader malfunctioning Inspect and replace parts

where necessary

Solenoid valve out of order Remove and check. Replace if

necessary

Unit does not speed up Voltage drop at motor terminals Consult power supplier. Use

correct size of cable

Unloader malfunctioning Inspect and replace parts

where necessary

Solenoid valve out of order Remove and check. Replace if

necessary

Blow-off silencer choked Replace

Air receiver pressure rises above

maximum and causes safety valve to

blow

Air pressure switch or pilot

valve incorrectly set or out of

order

Check. Replace switch or valve,

if necessary

Solenoid valve defective Remove and check. Replace if

necessary

Unloader malfunctioning Inspect and replace parts

where necessary

Blow-off silencer choked Replace

Relief valve blows Defective inlet valve in HP

cylinder head

Inspect and replace part(s) as

necessary

Relief valve not airtight Replace valve

Receiver does not hold pressure Check valve leaks Check for broken valve and

springs

Air leaks Check and correct as

necessary

Too frequent starting/too short

operating periods

Air pressure switch or pilot

valve incorrectly set

Increase pressure difference

Check valve leaks Check for broken valve and

springs

High oil consumption on LE/LT

compressors

Oil level too high Do not overfill crankcase. Keep

level in red circle of sight-glass

Piston ring(s) worn or broken Have condition of piston rings

checked

Instruction book

2920 7089 90 65

Loading...

Loading...