Safety Information LUM21 HR

8

© Atlas Copco Industrial Technique AB - 9836 1172 05

Noise (according to

PN8NTC1.2)

dB(A)

Determined sound

power level

Spread in method and

production

3

Vibration (according

to ISO 8662-7)

m/s

2

Measured vibration

value

< 2.5

Spread in method and

production

Declaration of noise and vibration

emission

These declared values were obtained by laboratory

type testing in compliance with the stated stan-

dards and are not adequate for use in risk assess-

ments. Values measured in individual work places

may be higher than the declared values. The actual

exposure values and risk of harm experienced by

an individual user are unique and depend upon the

way the user works, the workpiece and the work-

station design, as well as upon the exposure time

and the physical condition of the user.

We, Atlas Copco Industrial Technique AB, can-

not be held liable for the consequences of using the

declared values, instead of values reflecting the ac-

tual exposure, in an individual risk assessment in a

work place situation over which we have no con-

trol.

Service instructions

Service Instructions

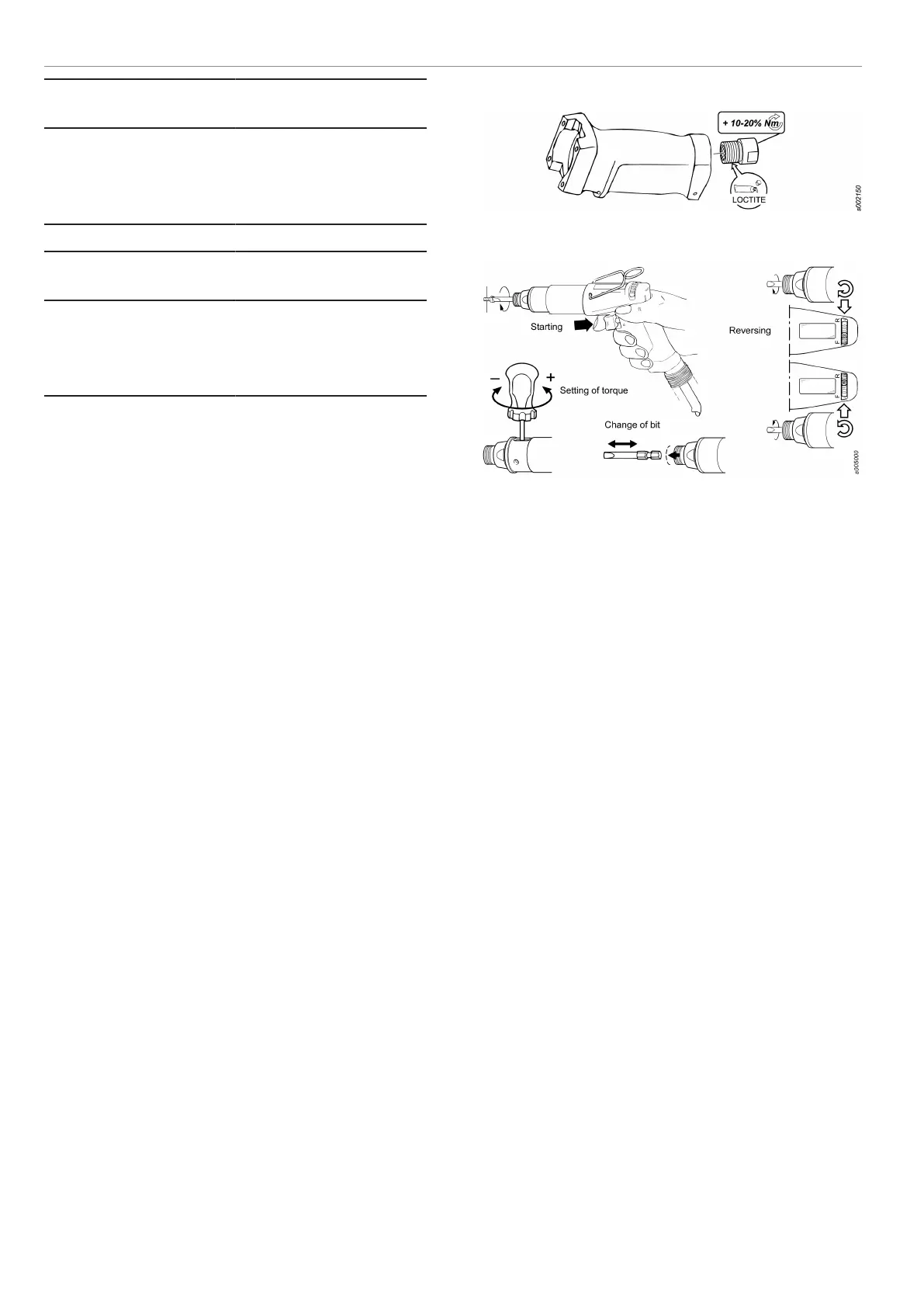

Tightening of threaded connections

The tightening torques indicated in the spare parts

list are established to achieve the correct clamping

force and to prevent the parts from coming loose.

When serviced these parts must be able to open up

without being destroyed. In special circumstances

(depending on application and usage) the parts

may however come loose after some time of opera-

tion. In such cases the torque could be increased

10-20% and if necessary some type of low or

medium threadlocking fluid could also be applied.

Example

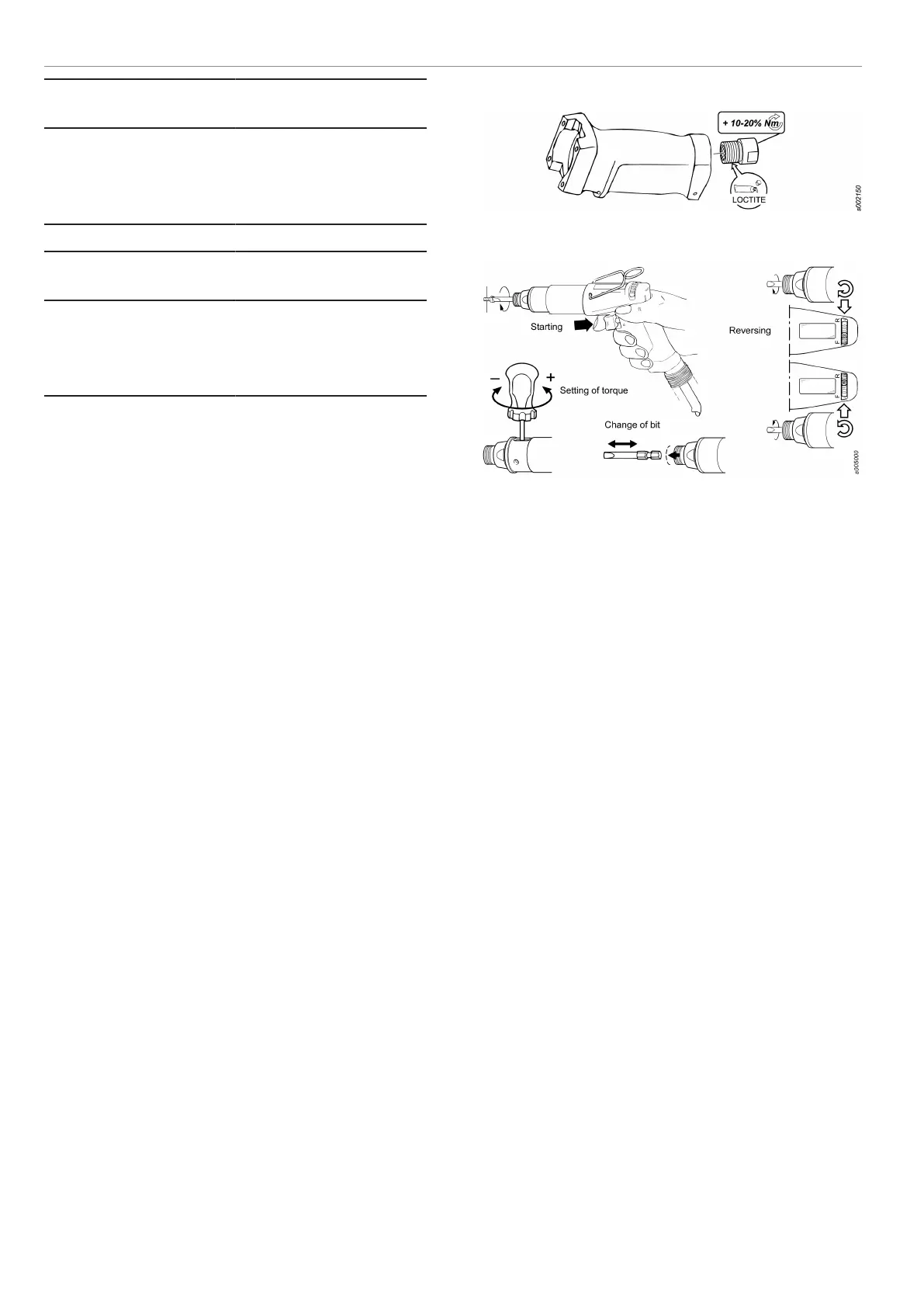

Operating Instructions

Air pressure monitoring, RE-signal S1

Reporting pneumatic assembly tools provide a

pneumatic signal that indicates which part of the

tightening cycle the tool has reached, by means of

variations in air pressure.

In the RE-Controller box timers are triggered when

certain pressure levels are reached.

Pressure level 1 (P1) starts a timer that checks that

the tightening cycle is not too short.

Pressure level 2 (P2) starts a timer that checks the

time taken from when the clutch has been released

to when the operator releases the trigger to ensure

that it is not too short.

The controller measures the differential pressure

over the motor.

It should be noted that the system does not mea-

sure torque! Regular check of installed torque/

torque output of the tool must be done separately.

The RE-Controller checks the air-line pressure.

One of the most common problems in air-line sys-

tems is pressure variations. If the pressure drops

too much the tool might stall and/or the torque will

not be correct. The RE-Controller will give a sig-

nal if the pressure drops too much.

Loading...

Loading...