Observe all the applicable national and regional

regulations on securing loads.

Installation

Before installing the hydraulic breaker on the carrier

or operating it, read the operation manual and safety

instructions provided by the carrier manufacturer.

Follow all instructions.

The carrier must have the appropriate hydraulic

system for operation of the breaker.

If the carrier is too large for the hydraulic breaker it

may lead to broken working tools and increased

wear. See "Technical data" for choosing suitable

carrier.

The safety equipment in the hydraulic system must

be checked for quality (CE mark, etc.), suitability and

functionability by a professional or authorised

supervisor before use.

Hoses and connections

WARNING Whipping hydraulic hose

Hydraulic hoses under pressure can whip

uncontrollably if screws loosen or are loosened. A

whipping hydraulic hose can cause severe injuries.

► Depressurise the hydraulic system before

loosening the connection of a hydraulic hose.

► Tighten the nuts on the connections of the

hydraulic hoses to the required torque.

Type of nipple: ORFS standard nipple. The nipple

dimensions can be found in the Spare parts list.

The quality of the hydraulic hoses must be 2SC

(according to EN 857) or better when connecting the

breaker to the carrier. If quick couplings are to be

used, we recommend using the 'Flat Face' quick

coupling. This type is sturdy and easy to clean. The

quick coupling pressure class must agree with the

carrier's working pressure.

Always clean the quick couplings before mounting

or dismounting. Always plug hoses and hose nipples

with tight and clean end caps when dismounting.

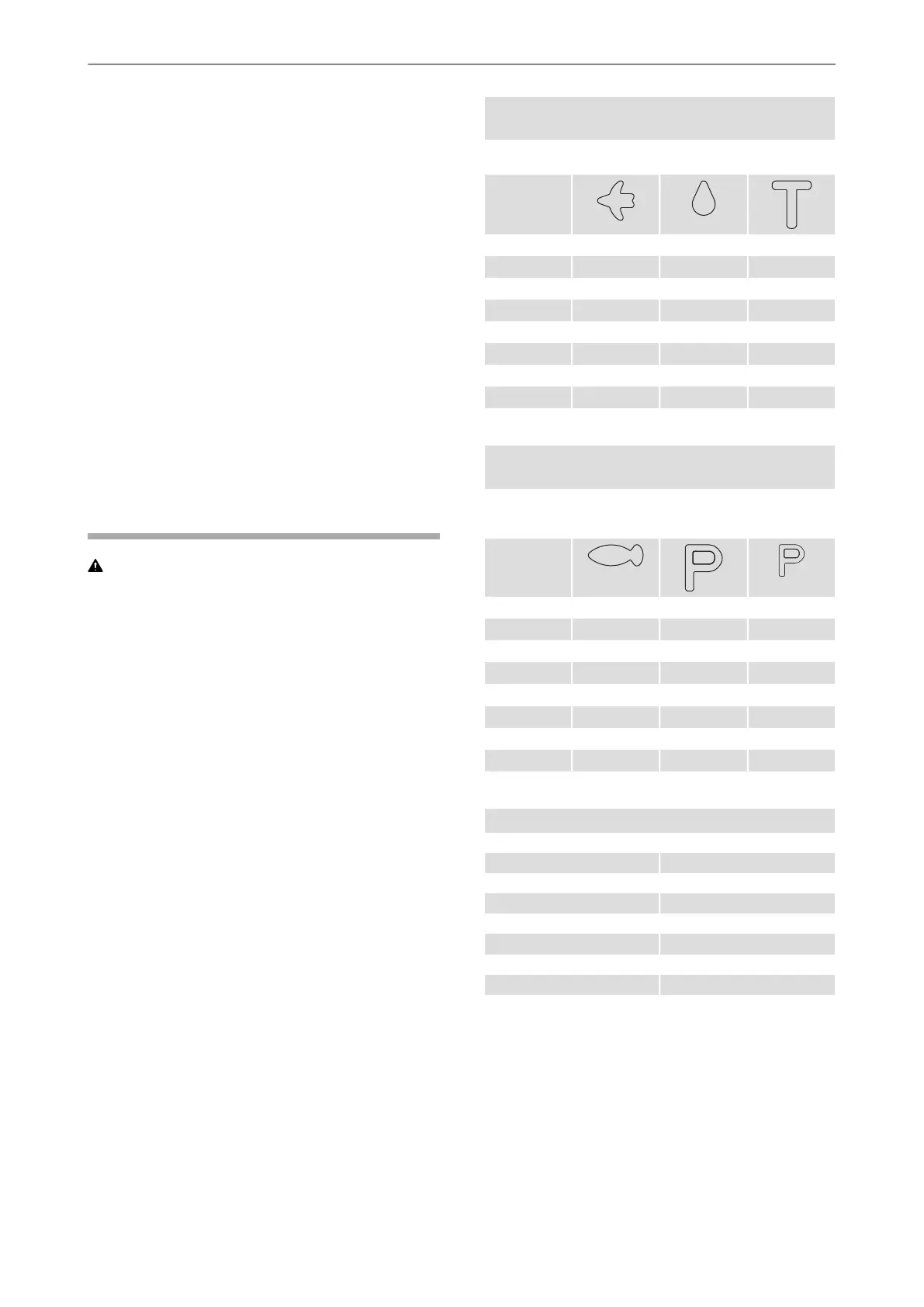

Hose connections

Right (As seen from operator’s seat)

Tank, return

line

Central

lubrication

Air flushing

Symbol

G

3

⁄

8

in.G

1

⁄

4

in.G

1

⁄

4

in.SB 52

G

1

⁄

2

in.G

1

⁄

4

in.G

1

⁄

4

in.SB 102

G

1

⁄

2

in.G

1

⁄

4

in.G

1

⁄

4

in.SB 152

G

1

⁄

2

in.G

1

⁄

4

in.G

1

⁄

4

in.SB 202

G

3

⁄

4

in.G

1

⁄

4

in.G

1

⁄

4

in.SB 302

G

3

⁄

4

in.G

1

⁄

4

in.G

1

⁄

4

in.SB 302 SC

G

3

⁄

4

in.G

1

⁄

4

in.G

1

⁄

4

in.SB 452

G

3

⁄

4

in.G

1

⁄

4

in.G

1

⁄

4

in.SB 452 SC

G 1 in.G

1

⁄

4

in.G

1

⁄

4

in.SB 552

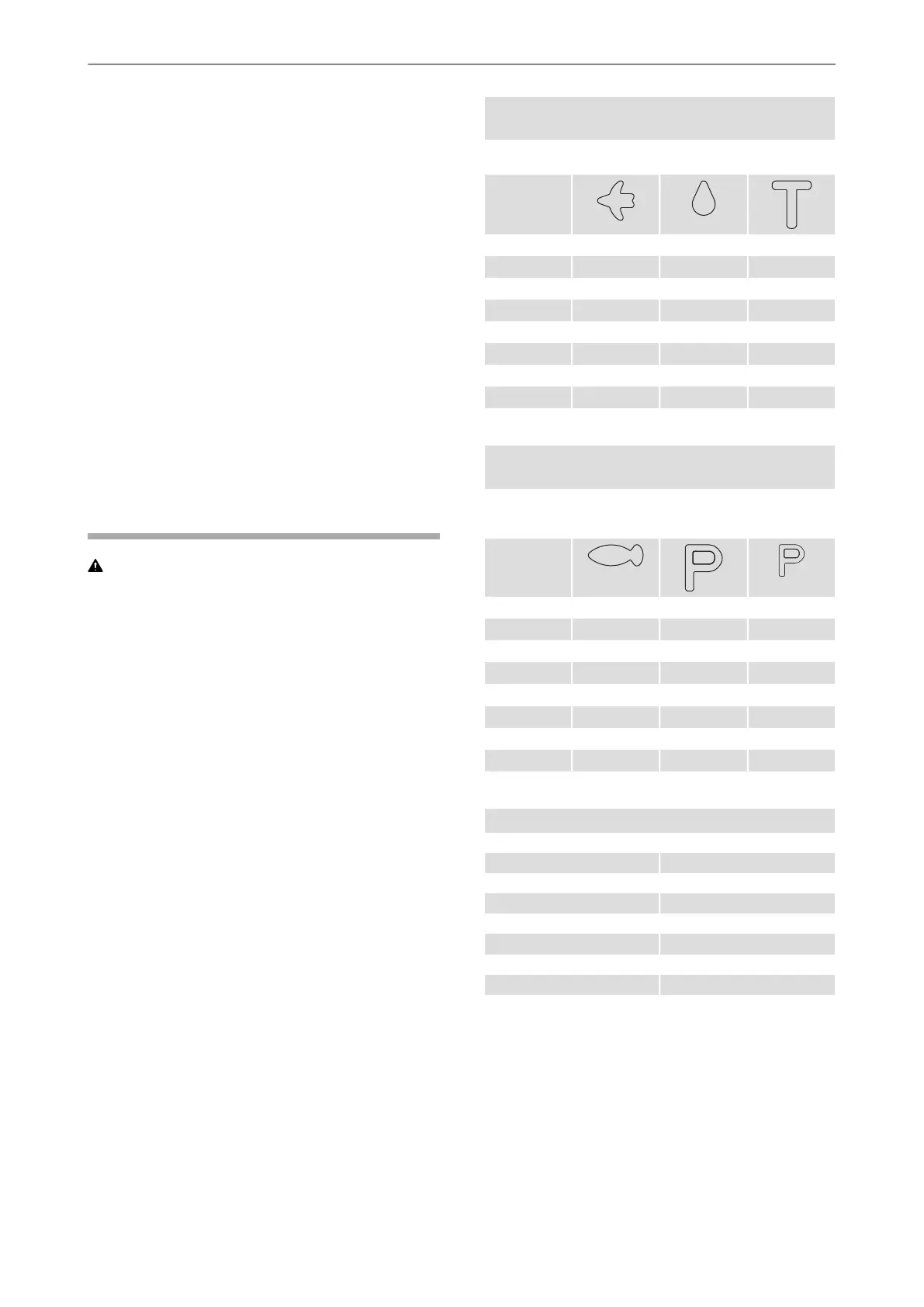

Hose connections

Left (As seen from operator's seat)

Pressure for

ContiLube II

micro

Pressure to

breaker

Water

Symbol

G

1

⁄

4

in.G

3

⁄

8

in.-SB 52

G

1

⁄

4

in.G

1

⁄

2

in.-SB 102

G

1

⁄

4

in.G

1

⁄

2

in.G

1

⁄

4

in.SB 152

G

1

⁄

4

in.G

1

⁄

2

in.G

1

⁄

4

in.SB 202

G

1

⁄

4

in.G

3

⁄

4

in.G

1

⁄

4

in.SB 302

G

1

⁄

4

in.G

3

⁄

4

in.G

1

⁄

4

in.SB 302 SC

G

1

⁄

4

in.G

3

⁄

4

in.G

1

⁄

4

in.SB 452

G

1

⁄

4

in.G

3

⁄

4

in.G

1

⁄

4

in.SB 452 SC

G

1

⁄

4

in.G 1 in.G

1

⁄

4

in.SB 552

Tightening torque for pressure and return hoses

60 NmSB 52

150 NmSB 102

150 NmSB 152

150 NmSB 202

210 NmSB 302

210 NmSB 302 SC

210 NmSB 452

210 NmSB 452 SC

300 NmSB 552

NOTICE The tightening torques in the table above

are valid when the pressure and return hose are

mounted directly on the hydraulic breaker's

connection nipple. If the pressure and return hose

are connected with an additional connection nipple,

another tightening torques must be used.

13© 2014 Construction Tools PC AB | No. 9800 0648 01l | 2014-06-11

Original instructions

Safety and operating instructionsSB 52, 102, 152, 202, 302, 302 SC, 452, 452 SC, 552

Loading...

Loading...