+05647%6+10/#07#.

25

(

7'.

5;56'/

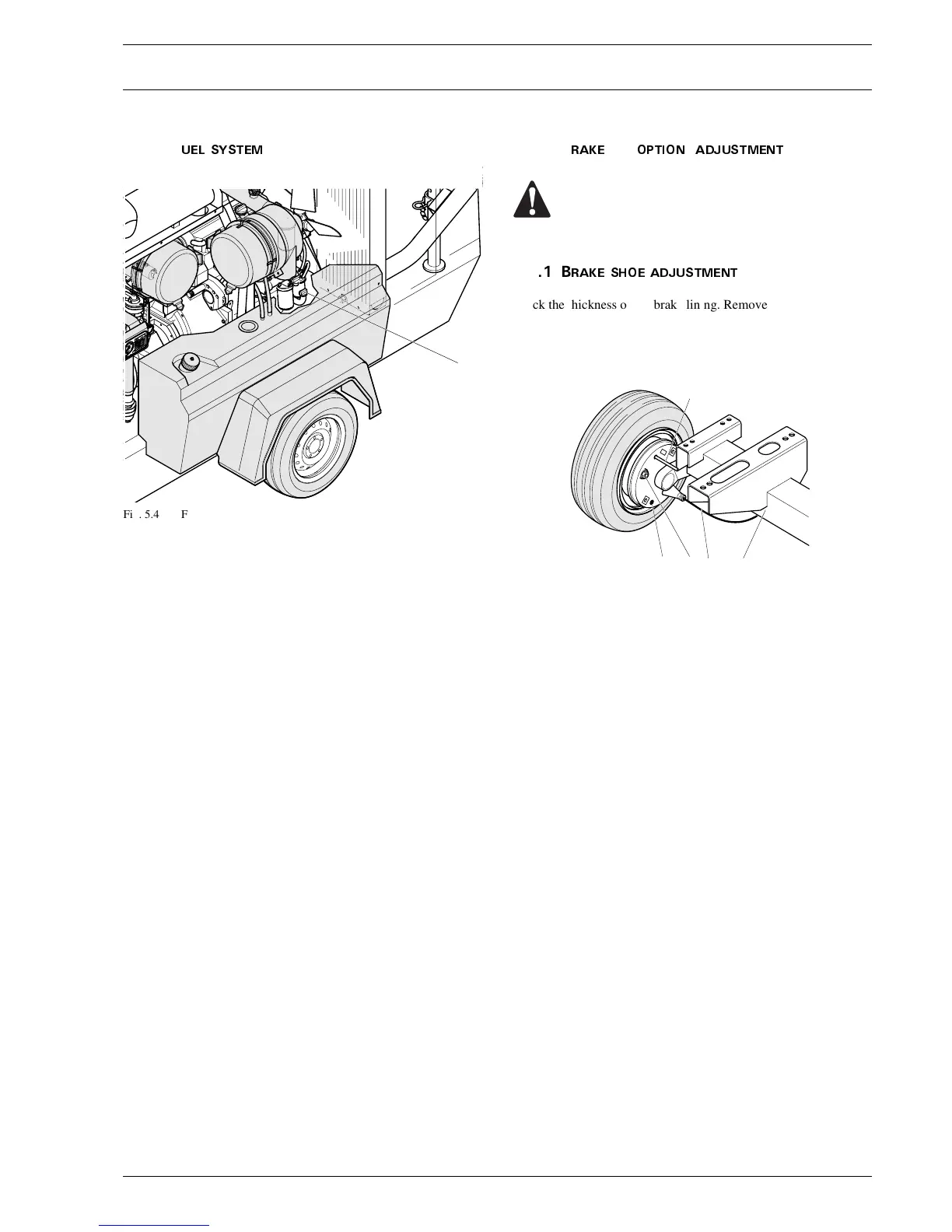

Fig. 5.4 Fuel filter

Replacing the filter element

1. Unscrew the filter element (1) from the adapter head.

2. Clean the adapter head sealing surface. Lightly oil the gasket of

the new element and screw the latter onto the header until the

gasket is properly seated, then tighten with both hands.

3. Follow the specific start procedure as discribed in section 1.3.2.

4. Check for fuel leaks once the engine has been restarted.

$

4#-'

126+10

#&,756/'06

$

4#-'

5*1'

#&,756/'06

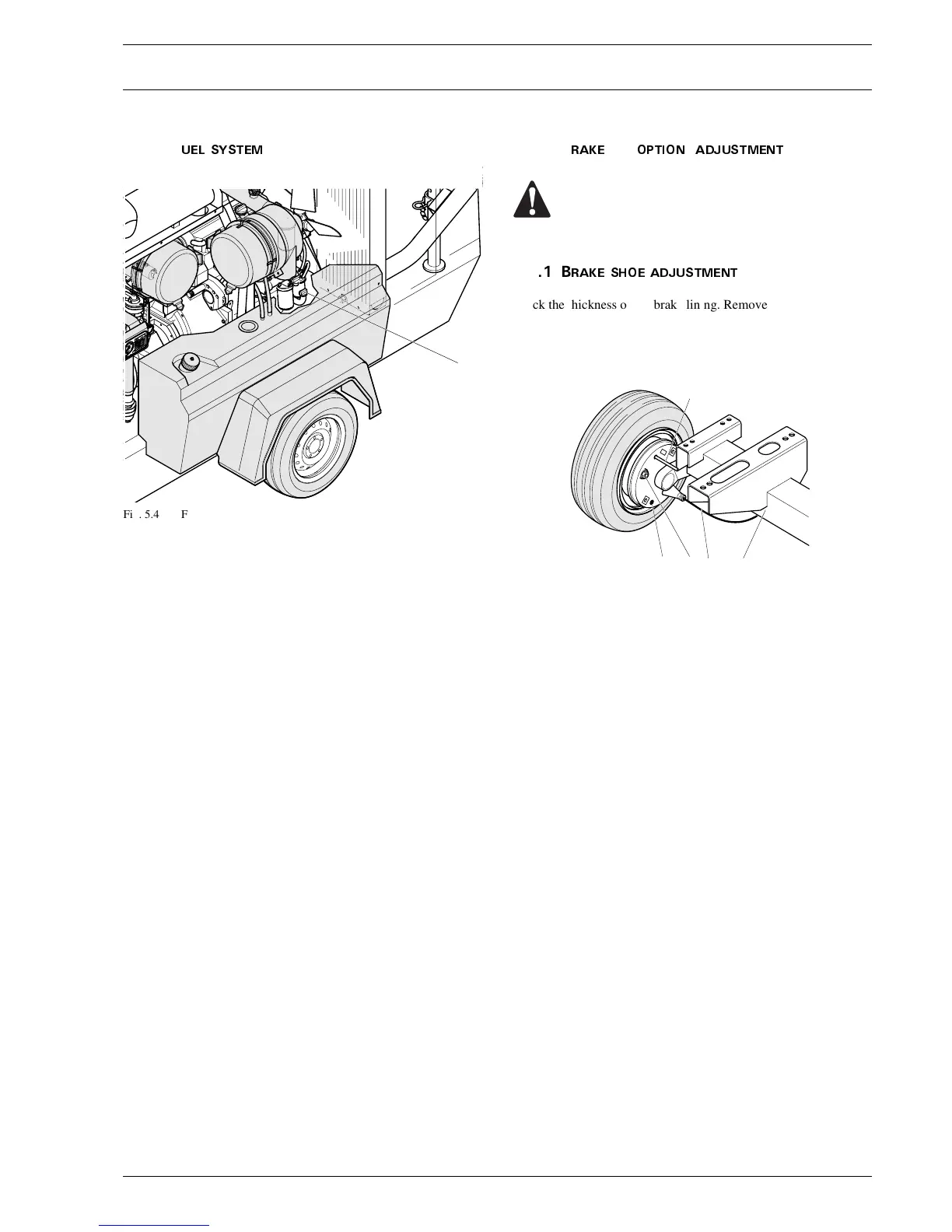

Check the thickness of the brake lining. Remove both black plastic

plugs (5). When the brake lining has been worn to a thickness of

1 mm or less, the brake shoes have to be replaced. After inspection and/

or replacement re-insert both plugs.

Fig. 5.5 Brake shoe adjustment

1 Adjusting bolt

2Axle

3 Brake cable

4Pin

∅ 4 mm

5Plug

Brake shoe adjustment re-establishes the brake lining-to-drum

clearance and compensates for lining wear.

Lift and support the compressor. Make sure that all brakes are off

(overrunbrake and hand brake lever). The brake cables must be free

from tension. Lock the swivel cams of the wheel brake from the outside

by means of a pin

∅ 4 mm (4) through the hole as shown in Fig. 5.5.

Turn the adjusting bolt (1) clockwise with a wrench till the wheel locks

up. Center the brake shoes by actuating the parking brake several

times.

Turn the adjusting bolt anti-clockwise until the wheel is running free

in direction of travel (approx. 1 full turn of the adjusting bolt).

Check the position of the equalizer (Fig. 5.7, 6) with the parking brake

actuated.

Perpendicular position of equalizer = identical clearance of wheel

brakes.

Re-adjust the brake shoes, if necessary.

To test, slightly apply the parking brake and check identical brake

torque on left and right side.

Remove locking pin (4). Remove clearance from brake cables.

Check all lock nuts (Fig. 5.7, 2).

1

%HIRUHMDFNLQJXSWKHFRPSUHVVRUFRQQHFWLWWRD

WRZLQJYHKLFOHRUDWWDFKDZHLJKWRIPLQLPXPNJWR

WKHWRZEDU

1

5

32

4

Loading...

Loading...