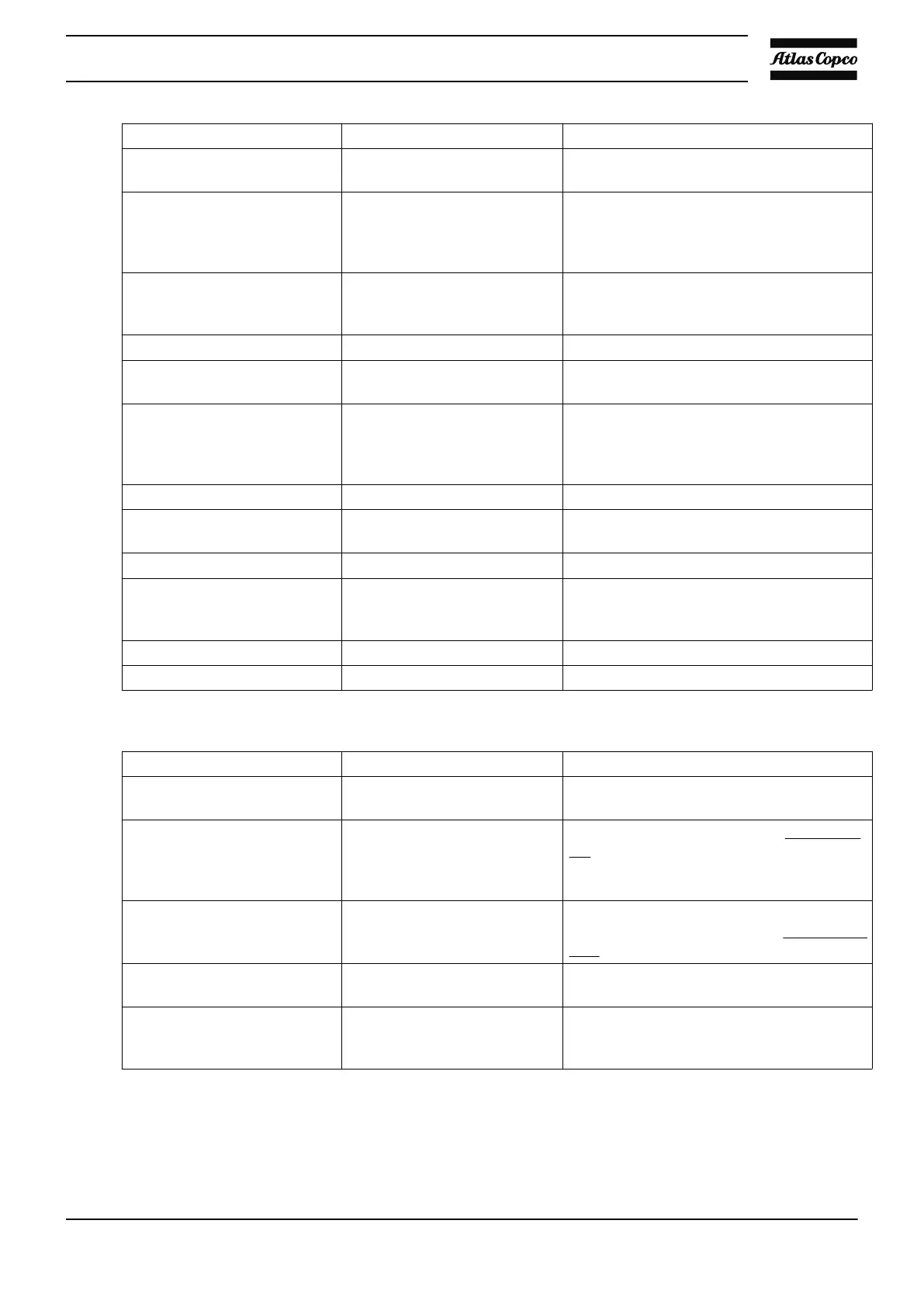

Condition Fault Remedy

Unloading pressure incorrectly

set

Check the controller setting.

On ZT compressors,

insufficient cooling air or

cooling air temperature too

high

Check and correct.

Condensate is not discharged

from condensate traps during

operation

Drain/pipe clogged Check and correct

Frozen drain piping Check and correct

Venting lines not/badly

assembled

Check and correct

Only on IC drain : intercooler

condensate check valve

defect/dirty/wrongly

assembled

Check and correct

Solenoid valve defect/dirty Check and correct

Manual operated solenoid

valve

Set valve to automatic operation

Level sensor defect/dirty Clean sensor or replace as necessary

Drain continuously discharges

air

Damaged/poor assembled

condensate drain (housing/

seals/valve/…)

Check and correct

Solenoid valve defect/dirty Check and correct

Level sensor defect/dirty Clean sensor or replace as necessary

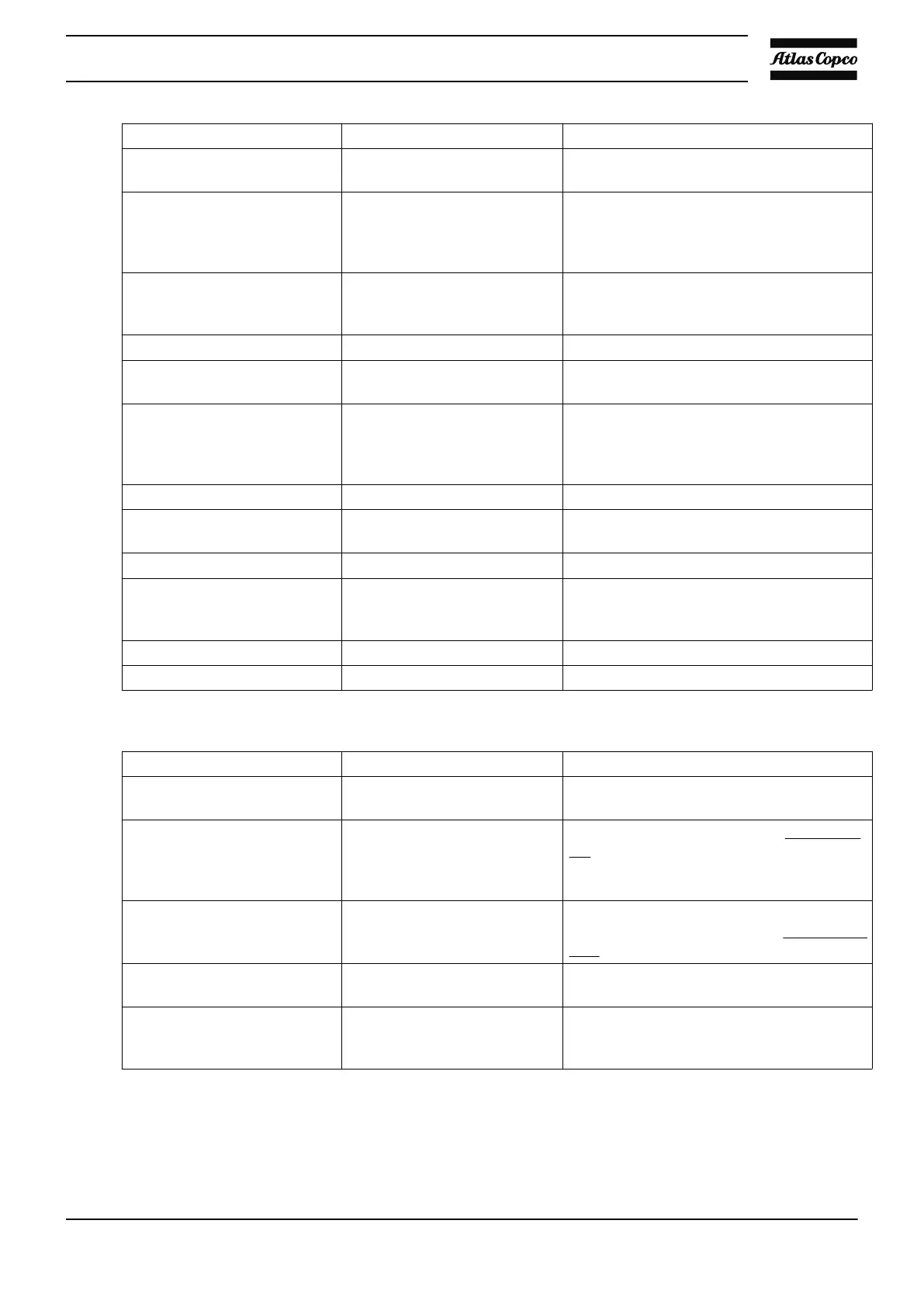

For Full-Feature compressors

Condition Fault Remedy

Pressure dewpoint too high

Compressor loading periods

repeatedly too short

Take necessary action to increase duration

of loading periods

Incorrect dryer adjustment

Adjust the dryer as specified in Initial start-

up . Never operate the dryer with a

pressure difference/nozzle fraction beyond

the specified range.

Operating pressure too low

Do not operate the dryer at a pressure

lower than the one specified in Compressor

data

Dryer rotor/motor does not

turn

Consult Atlas Copco Customer Center

Rotor compartment sealing

ring, sealing sectors and rotor

need inspection

Consult Atlas Copco Customer Center

Instruction book

2920 1815 04 295

Loading...

Loading...