ATS Systems Ultimate Chuck Installation and Operations Manual

INSTALLATION:

3.1 Installing the chuck to the machine

spindle

See 6.1 in OTHER INFO section of this manual for

parts identification.

3.1.1 Checking the chuck and machine spindle

• Check the machine’s spindle nose and flange, or

the finished machined adapter plate concentricity

and face runout. Maximum allowable runouts are

0.005 mm.

• All mating surfaces must be clean and free of

nicks, dents, chips, dirt, etc.

3.1.2 Installing the chuck

• Remove the chuck from the package, check for

damage and that it is complete.

• If there are any base jaws installed in the chuck,

unlock and remove them. (see this manual

section 4.1).

• You need to determine the actual maximum

stroke of your hydraulic cylinder and drawtube.

Actuate the cylinder and extend the drawtube

fully forward. Using calipers, measure from the

end of the lathe spindle nose to the front of the

drawtube and record the dimension. Now

actuate the cylinder and fully retract the

drawtube and record the measurement from the

same point on the spindle nose to the same point

on the end of the drawtube. Subtract these two

numbers and record here the actual drawtube

stroke for future reference.

Cylinder stroke = ___________

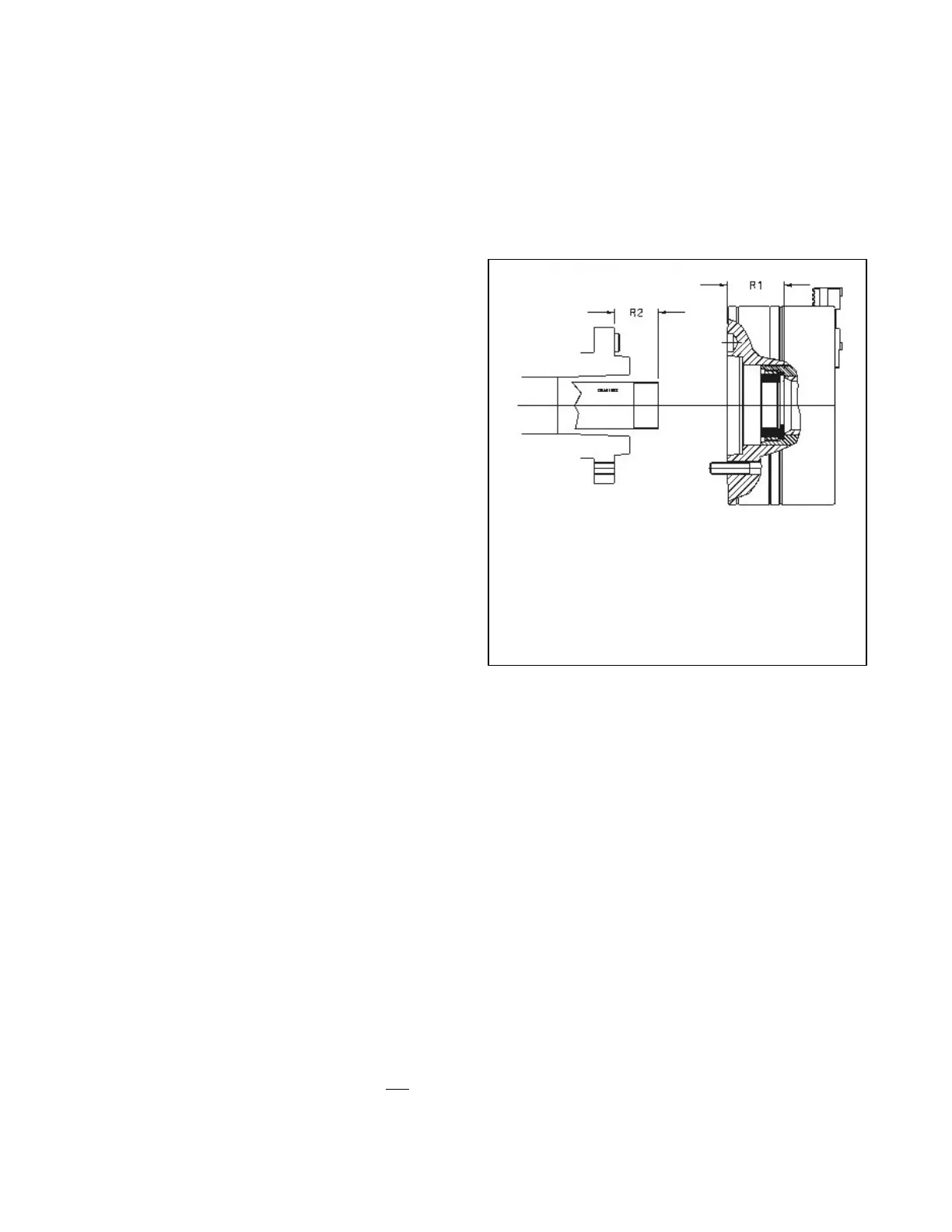

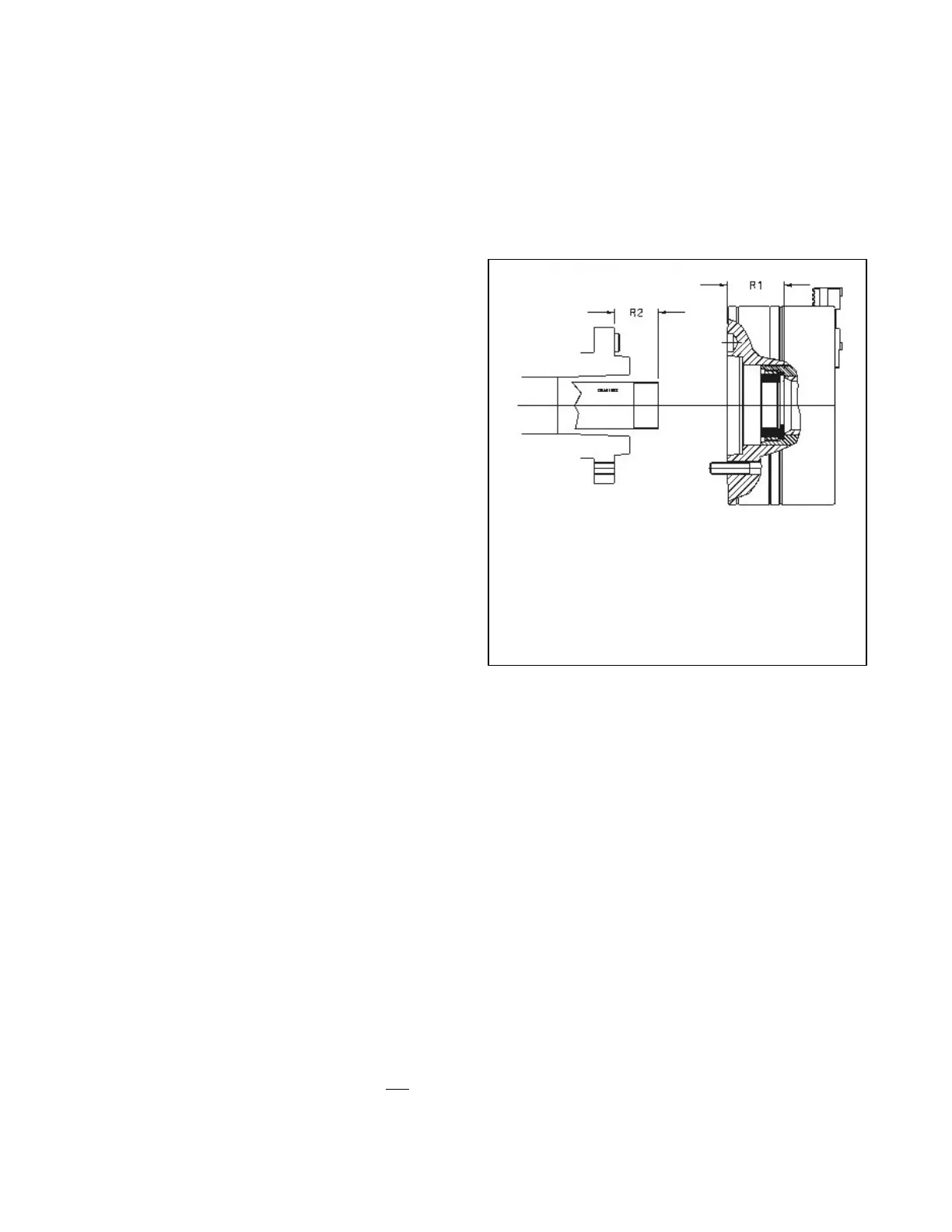

• Actuate the cylinder so that the

drawbar/drawtube once again extends fully

forward. (see figure 3.1).

• Push the chuck piston into its forward most

position.

• Confirm R2 dimension is .010" - .080" less than

R1 dimension measured to the inside bottom of

the drawtube adapter. If R2 is not shorter than

R1 STOP and rework the drawtube adapter if

possible or shorten the drawtube.

• Use supplied T-wrench (60) to tighten drawtube

adapter retaining ring (5) with drawtube adapter

(4) in place in chuck. Confirm drawtube adapter

is free to rotate but has less than .008" of end

play (allowable drawtube Z axis free motion).

Rework drawtube adapter if necessary. Remove

drawtube adapter retaining ring and remove

drawtube adapter. Screw drawtube adapter fully

onto drawtube to confirm tread fit.

• Put a small amount of never-seize or grease on

the front and the rear of the drawtube adapter

flange (not on the threads). Put the drawtube

adapter into the chuck keeping the never-seize

off of the threads. Install drawtube adapter

retaining ring with several drops of thread-locker

and tighten retaining ring with T-wrench. (Don't

use excessive thread-locker.)

Actuate lathe cylinder to push drawtube to

forward most position.

R1 = Push the chuck piston fully forward

and measure with a depth gauge.

R2 = R1 – 0.01" (max .080")

Fig 3.1

Loading...

Loading...