ATS Systems Ultimate Chuck Installation and Operations Manual

Keep base and top jaws screwed together for

subsequent use without the need to rebore. Always

tighten the jaw mounting bolts with the specified

torque.

4.6 Estimating chuck grip force loss and

approximate safe speed.

Proper determination of safe operating speed

requires a dynamic grip force gage that allows the

actual jaws in question to be run at operating

speed. Start the test at a slow speed and increase

speed until the minimum grip force to safely hold

and machine the workpiece is reached. Only this

empirical testing will guarantee accurate

conclusions. To approximately determine the

theoretical allowable speed for a particular set of

jaws, one can weigh the jaws, measure their center

of gravity by balancing them on a knife edge, and

then make some calculations. These calculations

assume the weights and measurements have been

made accurately, that the chuck is well

maintained, lubricated and working properly, that

the starting static grip force is accurately known

(cylinder size, pressure and resulting drawbar pull

x chuck grip/pull ratio specification), and that the

chuck is a high quality power chuck of modern

design and construction. Since there are so many

variables it would be dangerous to only make

these theoretical calculations and then run the

jaws at speed. But to give an estimate so that

empirical testing can be planned, the following

formulas can be used.

F

stati

c

=

lbs. of total starting grip force (all three or

two jaws) with the chuck not rotating,

using the draw bar pull (cylinder pressure)

planned for the job.

F@ speed = lbs. of total grip force (all three or two

jaws) you require remaining at operating

RPM. You will need to determine this

minimum grip force you require to safely

hold the workpiece.

w

ju

= lbs., weight of one jaw unit = one master

jaw plus one top jaw plus bolts (plus T-

nuts plus master jaw for conventional

chucks), or one monoblok jaw for wedge

bar type quick jaw change chucks, such as

the Ultimate Chuck. For conventional

wedge hook or lever chucks, don't use the

weight of just the top jaw or your theoretical

allowable speed will be way too high. (You

must

disassemble and weigh a master jaw to add to

the top jaw weight. When you do this you'll also

want to determine the center of gravity and

record these figures for future use.)

r

c

= in., radius dimension from centerline of chuck

to the center of gravity of the jaw unit. For quick

jaw change chucks where the entire jaw unit can

be removed this can easily be done by balancing

the jaw unit on a knife edge, marking the balance

point and then inserting the jaw into the chuck to

measure the distance from the chuck centerline

to the balance point. For chucks with normal

master jaws this radius is more difficult to

determine.

n = RPM, speed of rotation

n

max

= RPM, theoretical approximate maximum

allowable speed for the residual grip force you

determined is required. a = number of jaws (three or

two)

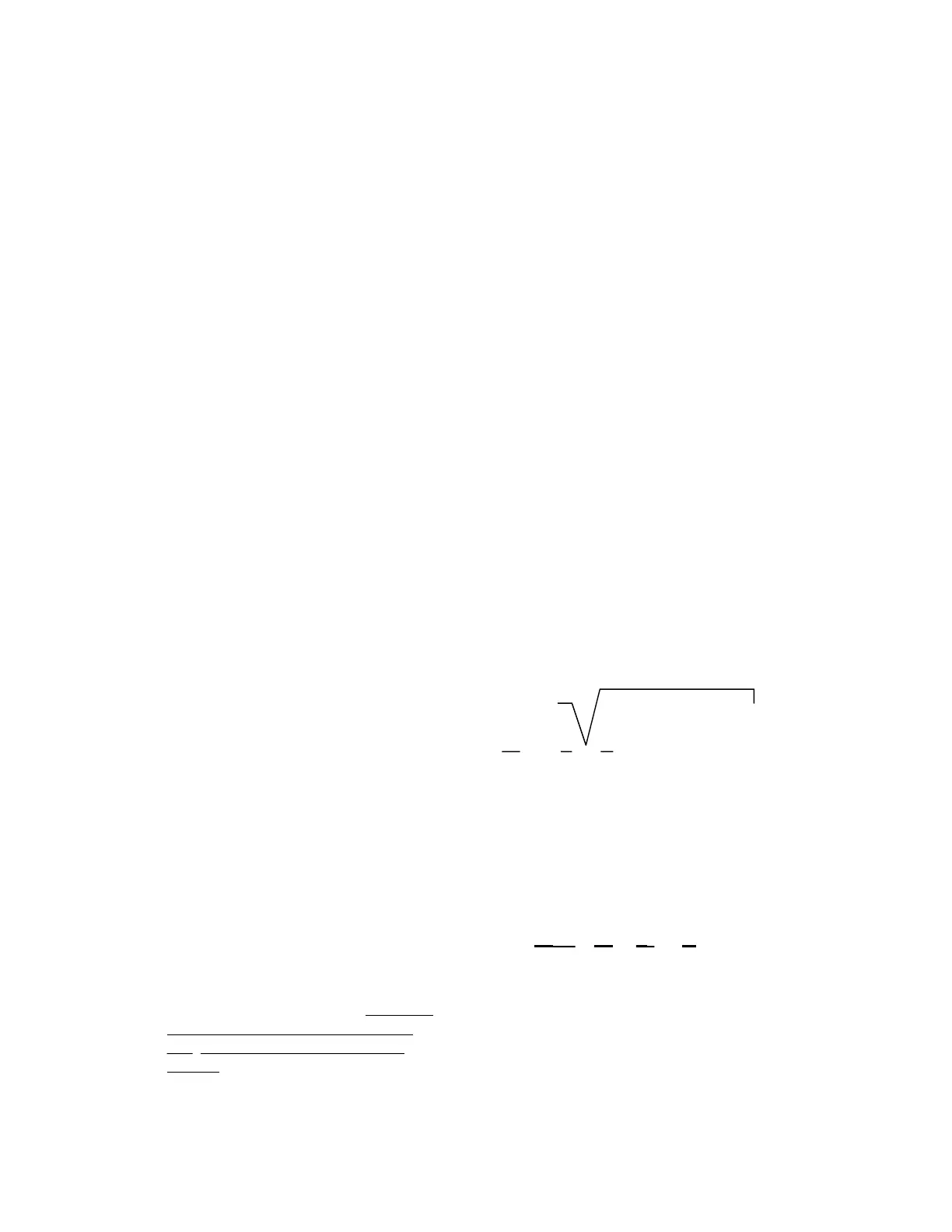

Calculated maximum speed:

nmax = Fstatic - F@ speed x 188

w

ju

x r

c

x a

Grip force loss (all three jaws, lbs.):

= w

ju

x a x r

c

x n

2

35,196

Example 1:

Ultimate Chuck size 210 (8") with full size monoblok

soft jaw gripping a 2" diameter part. How fast can the

Loading...

Loading...