ATS Systems Ultimate Chuck Installation and Operations Manual

reach the internal components of the

chuck.

• To ensure good grease distribution, inject one

shot of grease into each of the three grease

fittings, actuate the chuck full stroke several

times, and then inject a second shot of grease

into each of the three fittings. Check the

clamping force with a grip force gauge.

• After each 50 clamping strokes it is advisable

to actuate the chuck several times without

gripping a workpiece so that the chuck is

stroked to its extreme limits. When this is

done, lubricant that has been displaced is

returned to the pressure surfaces and the

clamping force is retained for a longer period

of time without re-lubrication.

• Depending on the application and the

workpiece materials being machined, the

chuck will periodically need to be

disassembled and cleaned. After cleaning, all

internal parts must be coated with a film of

KO5 grease, and the chuck body cavities at

either end of the wedge bars filled 50% with

KO5 grease. Each time the chuck is actuated

and the wedge bars stroke, this “reservoir” of

grease is pumped back through ports in the

wedge bar to lubricate critical surfaces.

• It is recommended that the clamping force be

checked using a grip force gauge before

beginning a new production batch and

between maintenance checks. Only regular

checks can guarantee safety.

5.2.2 Lubricating jaw guideways

When changing the base jaw or one-piece jaws,

the teeth and jaw guideways must be cleaned

and lightly greased with ATS K05 grease.

Ultimate Chucks were designed primarily for

JIT applications with frequent jaw changeover.

No grease fitting ports lubricate the jaw

guideways. Whenever jaws are changed,

inspect the chuck guideways for cleanliness and

put a film of grease on the sliding surfaces of

the master base jaws before inserting them into

the chuck. For high volume production

applications when jaws aren’t changed

frequently, the jaws should be removed once

per shift (depending on machining cycle time),

cleaned and re-lubricated. Optional master

base jaws with grease fittings are available as

special order.

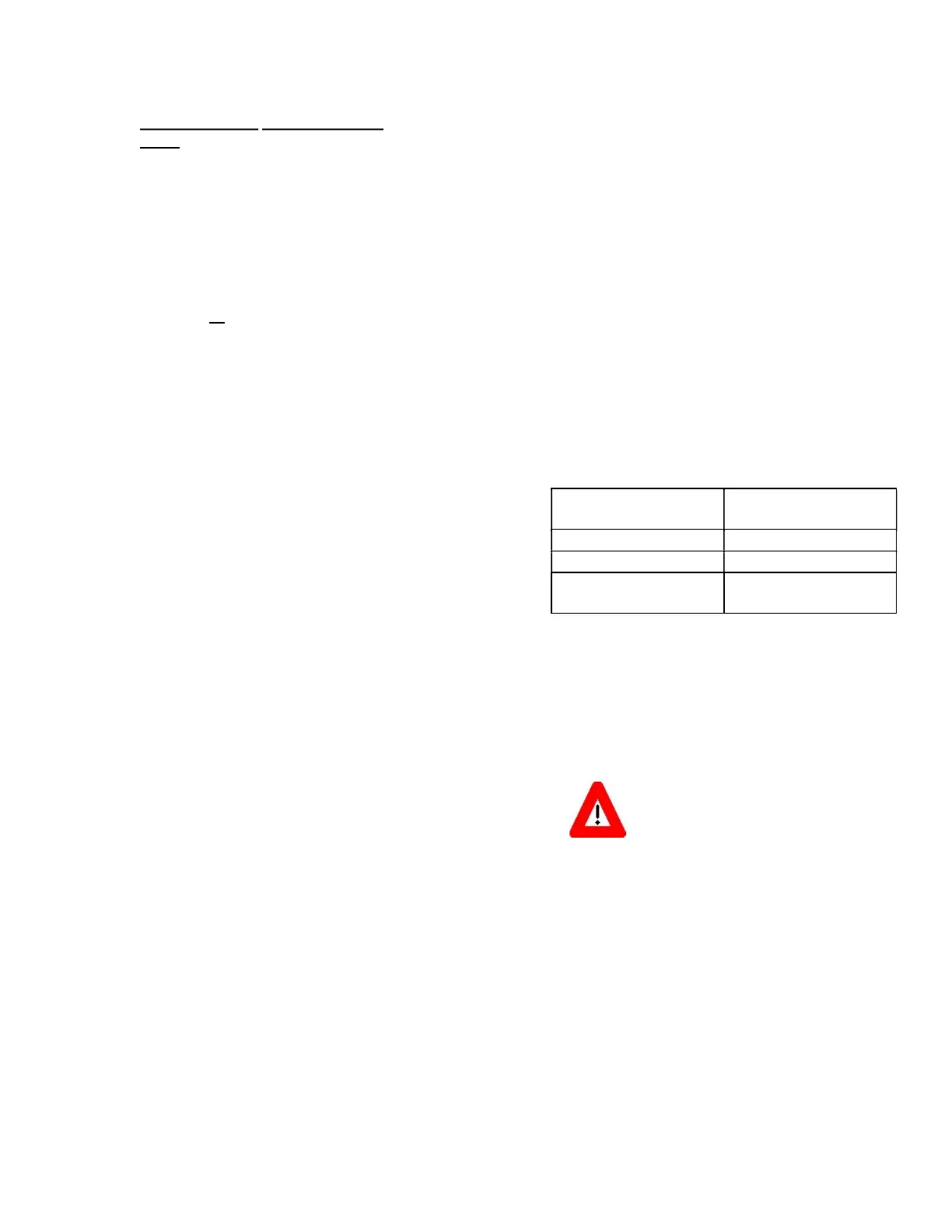

5.2.3 Lubrication and maintenance frequency

Depending on operating conditions, check the

function and the clamping force after the length

of operation specified in the table below.

Clamping force must be measured with a grip

force gauge.

Lubricate and test the chuck at the following

intervals:

Operating Hours

Amount of

Contaminants

20-30

Normal amount

8

High amount

1000-1500

Total disassembly and

cleaning of chuck

The base jaws must move easily and

smoothly at the lowest possible operating

pressure (cylinder).

WARNING

If grip force has dropped, or if base jaws and

piston can no longer be moved freely, then it is

necessary to immediately take the chuck out of

operation, disassemble, inspect, clean, repair as

required and re

lubricate it.

Loading...

Loading...