11

Mechanical installation

Cooling water loop installation

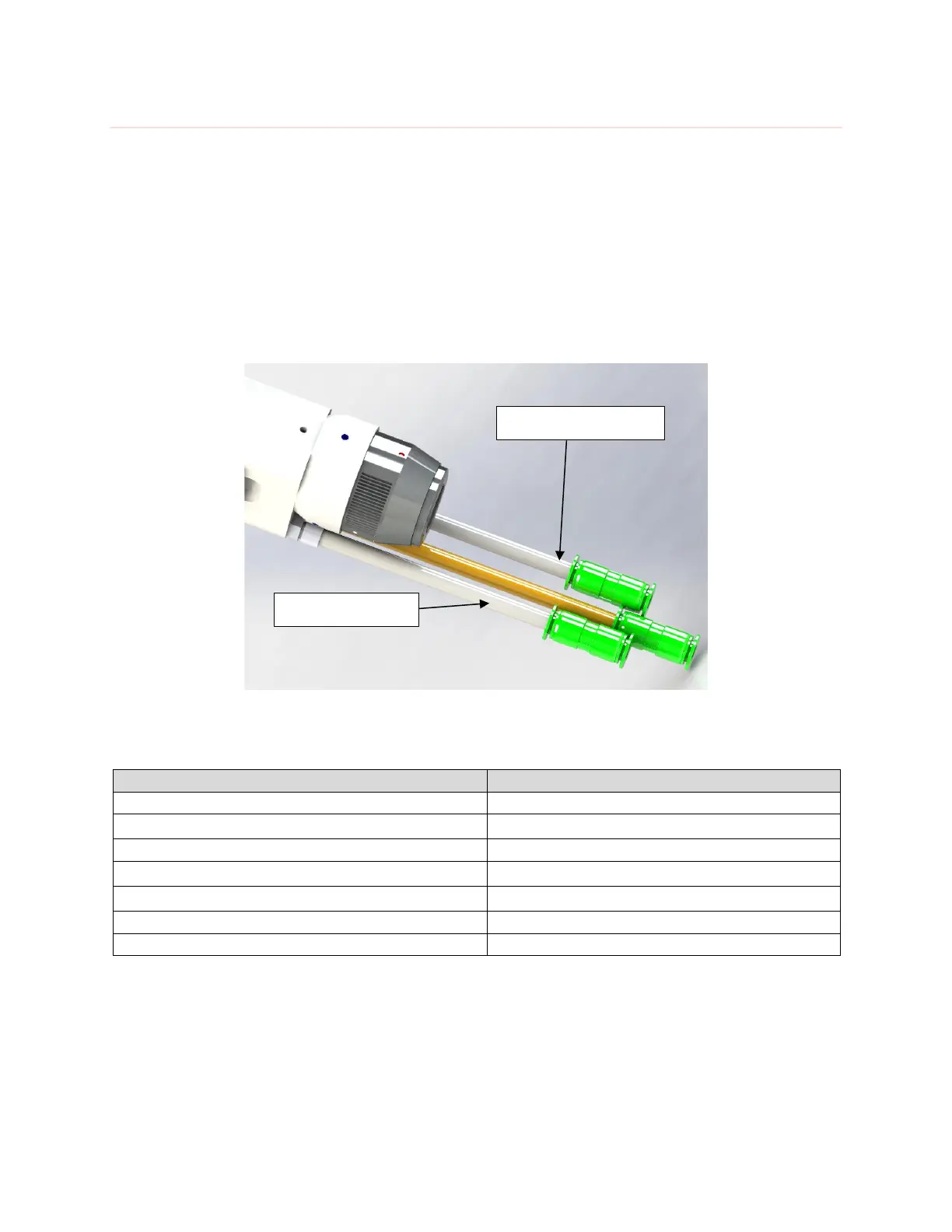

The HW970 handheld welding head is equipped with a set of cooling water channels. It

should be noted that when the laser power is greater than 500 watts, it is recommended

to use water cooling. From Figure 3, you can see the position and number of the water

cooling ports, and the table below lists the recommended water flow speeds in detail.

The design of the water-cooling interface is a closed loop system. External water supply

can be used freely, but the requirements in the list must be met.

Figure 3 HW970 water cooling interface

Loading...

Loading...