15

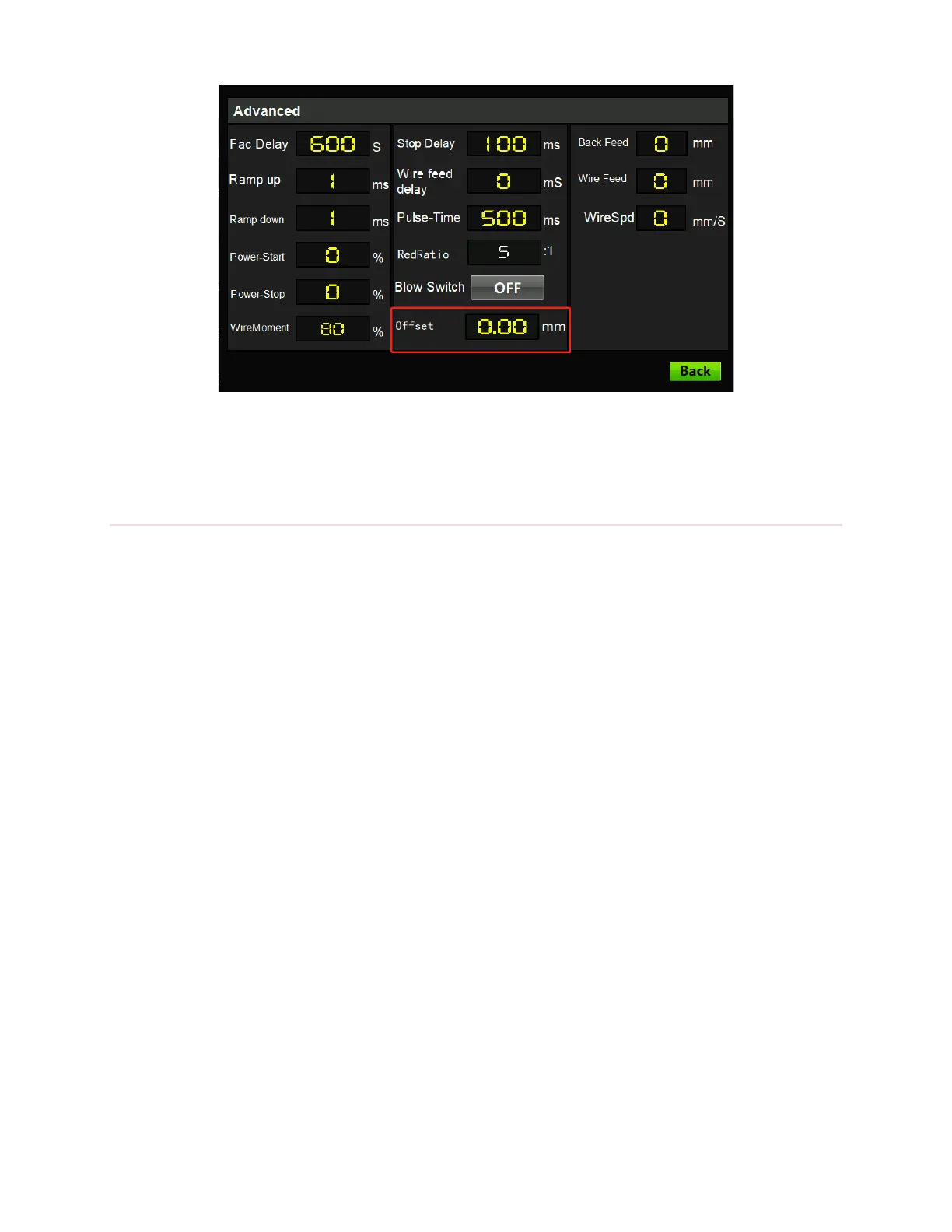

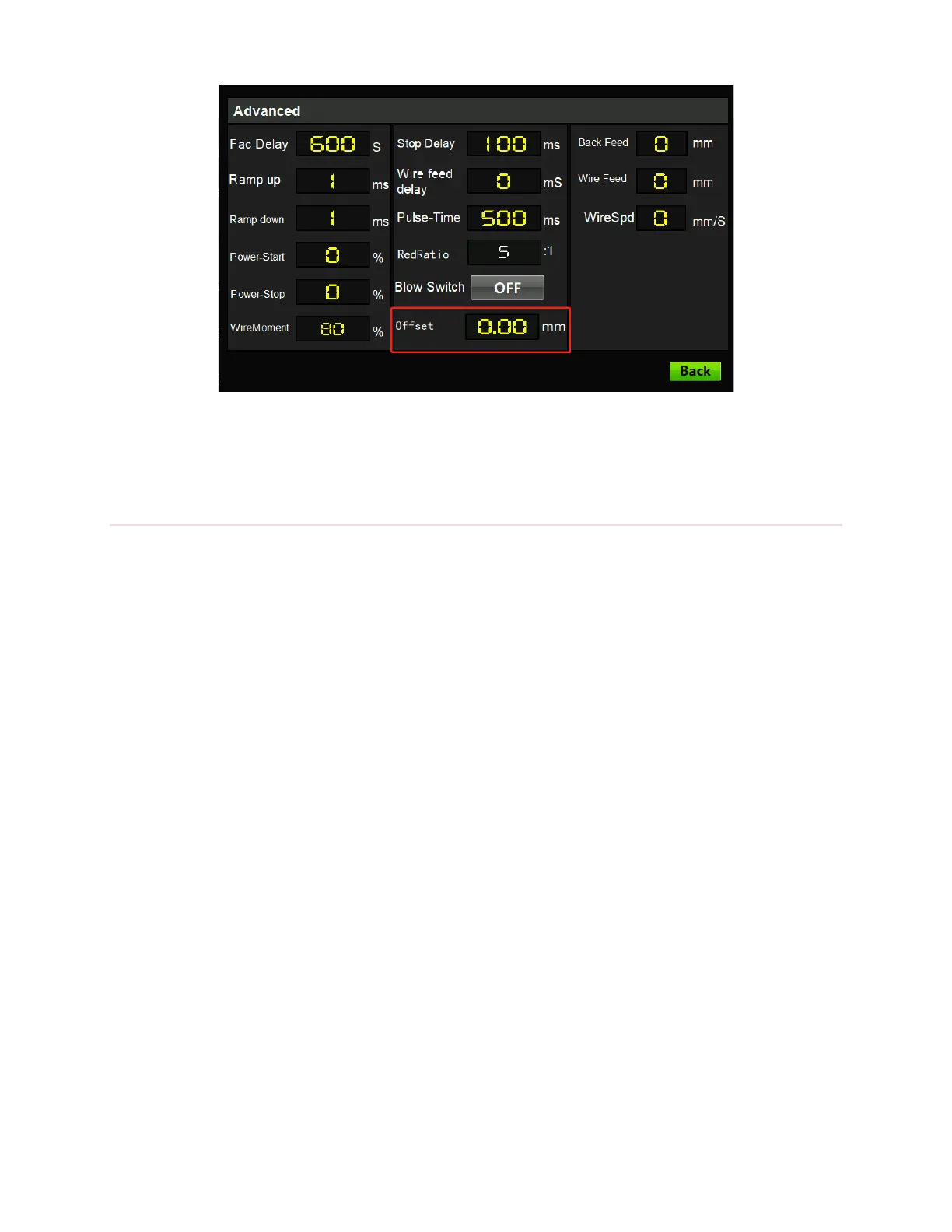

Figure 8 Adjusting the optical core offset parameters

Maintenance

Welding head cleaning and maintenance

When the welding head is used, a layer of black ash is attached to the copper

nozzle. This is the spark sputtering after the metal is heated, and then attaches to the

nozzle. There is also some dust in the air. After use, wipe the nozzle gently with a clean

cloth. Then, clean the dust on the welding head; in a relatively clean environment, pull

out the drawer and check whether the protective lens is clean. When the welding head

is not in use, plug the copper nozzle with tape or a rubber cap to prevent dust from

entering the lens. If you unplug the fiber connector, immediately block the hole of the

fiber input connector (QBH) with a dust cap to prevent dust from entering the fiber

connector.

Clean the lens

There is a lower protection glass at the front of the welding head to protect the focusing

lens. When impurities or foreign matters are attached to the protection glass, the lens

will be damaged. Therefore, the lens needs to be maintained regularly. It is

recommended to check it before start. Please refer to Figure 9 for lens structure.

Loading...

Loading...