9

System 2000/2002 EN 353-1/A1:2017 CSA Z259.2.1-98

Eagle DS EN 353-1/A1:2017 CSA Z259.2.4-15

Harness EN 361 ANSI Z359.11 CSA Z259.10

Read supplied instructions prior to use. Min.distance 6 m (19.7 feet) between users.

Maximum number of users: 3. Systems must be inspected by a certified AVANTI technician

annually under normal use or inmediately in the event of a shock load as a result of a fall.

Only AVANTI replacement parts may be used with the system.

www.avanti-online.com

P: (+34) 976149524

Production date:

Serial No.:

WARNING

Using replacement parts,

components not approved by

AVANTI or modified runners with

the rail system could result in

serious injuries or death.

Use of Personal Protective

Equipment is mandatory

FOLLOW ALL INSTRUCTIONS

0200

Date of commissioning:

Eagle DS

EN 353-1/A1:2017

Type: Rail Mount Size: AVANTI Fall Protection Rail Only. Read and follow all

instructions before use. Inspect device prior to each use.

User weight:

40 - 136 kg

Serial No.: Production date:

www.avanti-online.com

P: (+34) 976149524

0200

Avanti Shock Absorber CE

for Avanti Fall Arrest System

EN 353-1/A1:2017

No:

Expire:

Runner 2000/2002

EN 353-1/A1:2017

Type: Rail Mount Size: AVANTI Fall Protection Rail Only. Read and follow all

instructions before use. Inspect device prior to each use.

User weight:

40 - 136 kg

Serial No.:

www.avanti-online.com

P: (+

34

)

976149524

Production date:

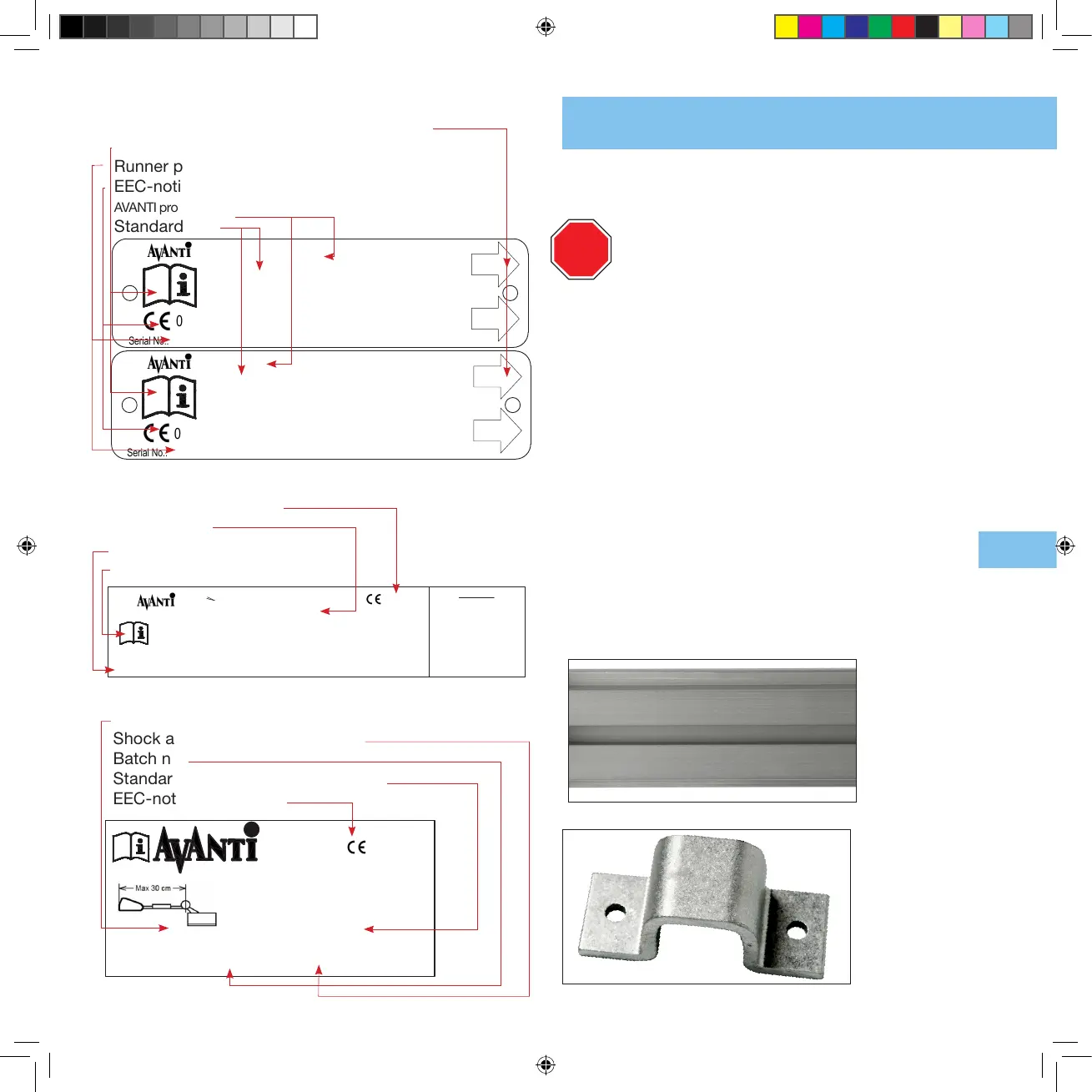

Runner rating plate

Upward direction when mounted onto rail

Read instructions before use

Runner production no.

EEC-notied body no.

AVANTI product name (Runner System 2000/2002 or Eagle

DS

)

Standard no.

3.4 Marking

Shock absorber label

Max distance between runner and harness 0,3 m

Shock absorber expiration date

Batch no.

Standard EN no. for shock absorber

EEC-notied body no.

Safety rail rating plate

EEC-notied body no.

Standard no.

Production batch no.

Read instructions before use

4 Installation

4.1 Installation requirements

A certified technician shall be in charge of the FPS installati-

on. The certified technician shall take full responsibility for the

installation and shall guarantee that it is done in accordance

to these instructions.

a) The FPS shall only be installed with original system parts.

b) All FPS elements shall be checked on site, even if the ladders are

supplied with the rails already tted.

c) The vibrations and torsional stress are absorbed by the ladder

joints, not by the safety rail.

d) Ensure that the ladder intended for mounting the FPS complies

with the requirements of EN 131 and EN ISO 14122. The internal

rung width shall be minimum 340mm (all AVANTI ladders meet this

requirement).

e) The ladders with rung geometries different to AVANTI‘s may call

for special rung ttings. Prior to installation, these ladders shall be

calculated, tested and approved by AVANTI.

f) Before installing the rail system, ensure that all parts are present.

Refer to the parts list supplied with the FPS.

g) The ladders shall be installed vertically with a maximum inclination

of -5º / +15º.

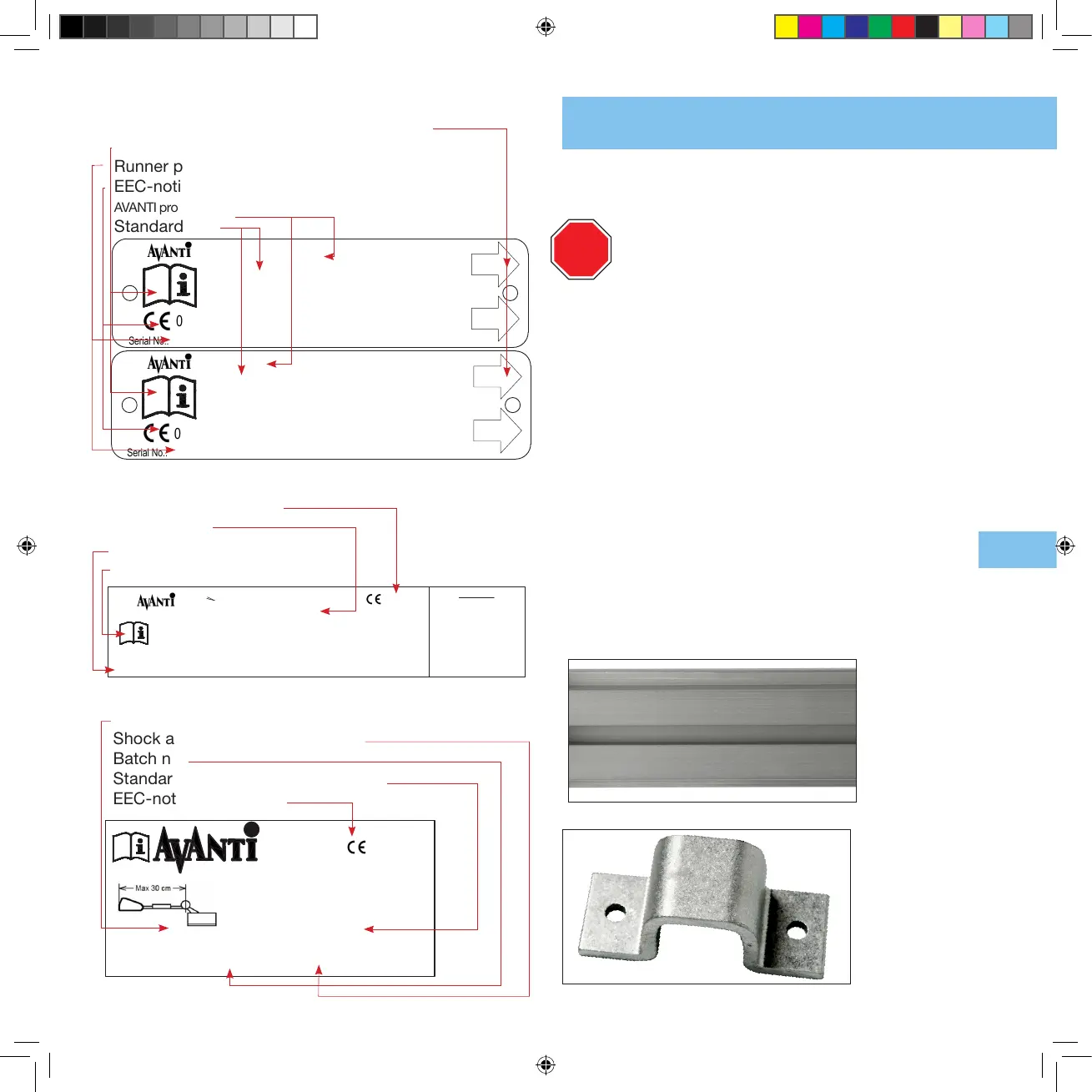

h) The parts of the safety rail system to be installed are shown below.

Rung tting

Safety rail section (backside)

Loading...

Loading...