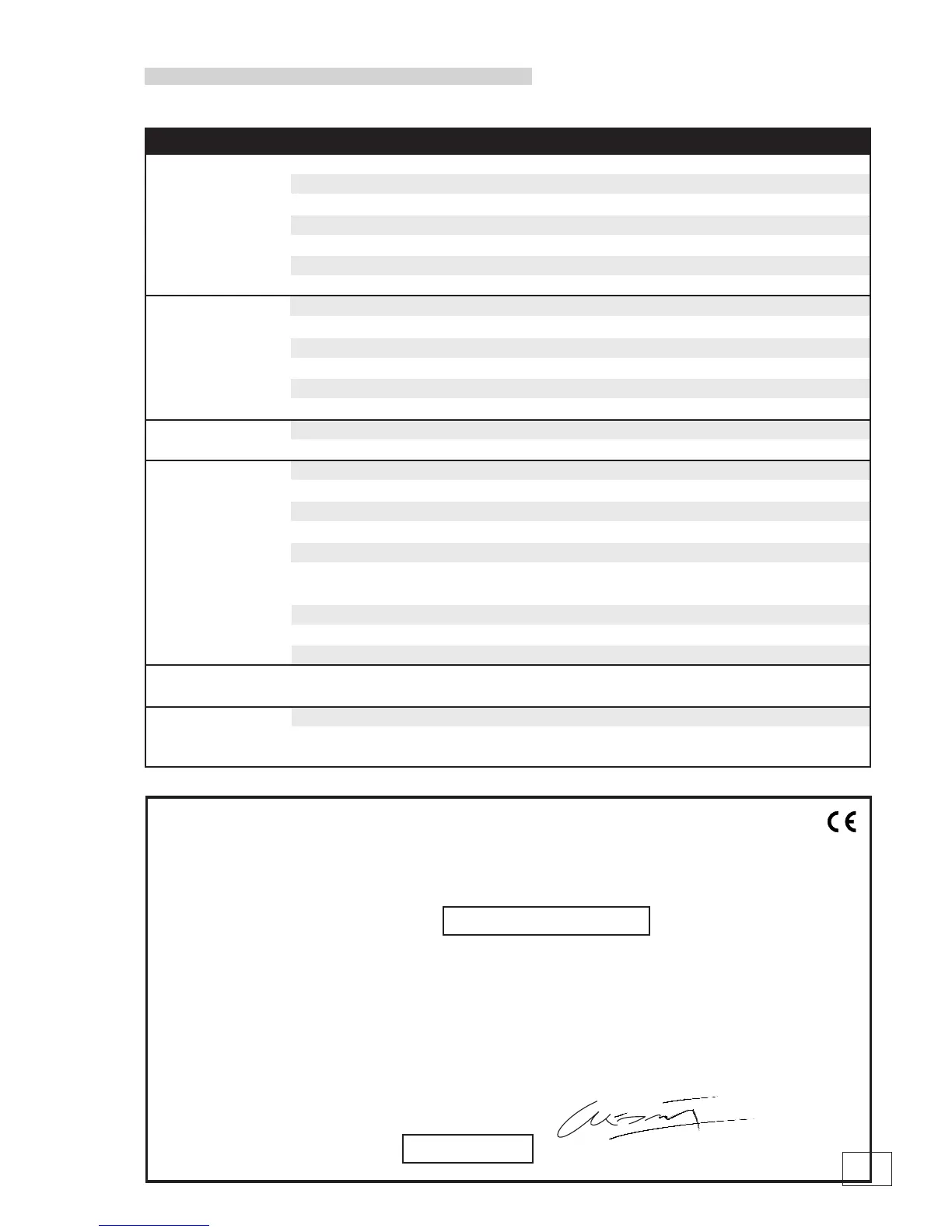

Declaration of Conformity

We,

declare under our sole responsibility that the product

Serial Nº ..............................................

to which this declaration relates is in conformity with the following standards or other formative documents

F

A U L T D I A G N O S I S

33

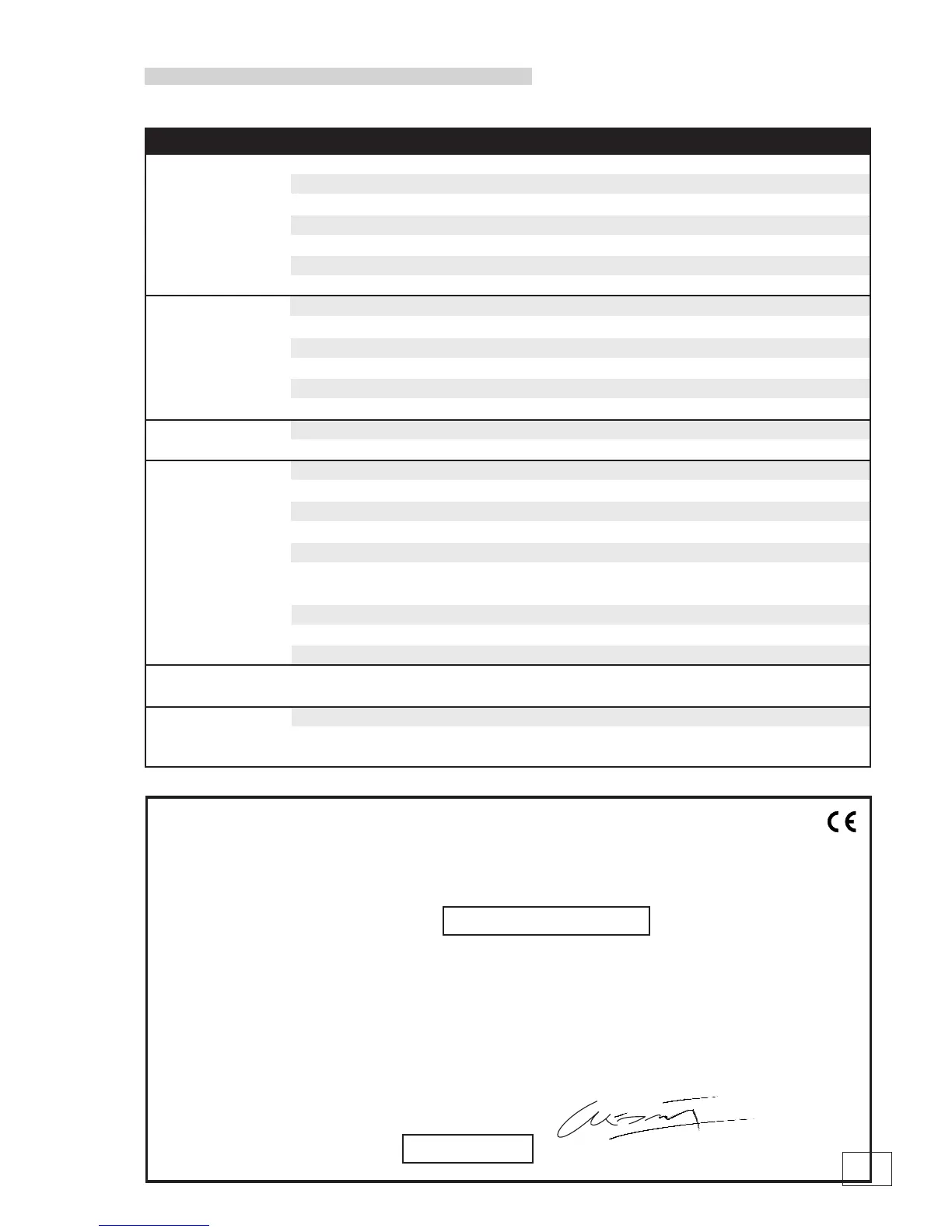

SYMPTOM POSSIBLE CAUSE REMEDY

Tool will not place ➝ Low air pressure. ➝ Increase air pressure.

fastener. ➝ Lack of lubrication. ➝ Lubricate tool at air inlet point.

➝ High broach load. ➝ Check fastener grip and application hole size.

➝ Check for correct size mandrel.

➝ Worn or broken tail jaws. ➝ New tail jaws.

➝ Tail jaws switched off. ➝ Switch on tail jaws.

➝ Air in hydraulic system. ➝ See ‘Priming Procedure’, on page 30.

‘Mandrel Slip’ - jaws will ➝ Worn or dirty tail jaws. ➝ Clean or renew as necessary.

not grip mandrel. ➝ Insufficient air pressure/volume. ➝ Increase air pressure/volume.

➝ Tail jaw switch inoperable. ➝ Replace switch.

➝ Air leaks to tail jaws. ➝ Renew ‘O’ rings on piston 8.

➝ Mandrel broken and not reaching tail jaws. ➝ Replace mandrel.

➝ Defective non-return valve. ➝ Replace non-return valve.

Jaws will not release ➝ Dirty tail jaws or jaw housing. ➝ Clean and lubricate.

mandrel. ➝ Faulty tail jaw switch. ➝ Replace ‘O’ rings.

Fasteners will not feed ➝ Tail jaws not switched on. ➝ Switch on tail jaws.

through nose jaws. ➝ Worn tail jaws. ➝ Renew tail jaws.

➝ Cursor orientation incorrect. ➝ Refit, ensuring correct orientation.

➝ Incorrect nose jaws. ➝ Fit correct nose jaws.

➝ Mandrel follower spring not fitted. ➝ Fit correct mandrel follower spring.

➝ Incorrect gap between fastener head and nose jaws ➝ Set gap to 1.5mm - 3mm (

1

/16” -

1

/8”).

when loaded. See ‘Loading the Tool’, on page 6.

➝ Cursor sticking. ➝ Clean and oil cursor.

➝ Weak outer spring around cursor. ➝ Renew cursor.

➝ Incorrect mandrel follower spring fitted. ➝ Fit correct mandrel follower spring.

Excessive tail jaw wear. ➝ High broach load. ➝ Check application hole size and thickness and

fastener grip capability.

Feeding more than ➝ Mandrel slip. ➝ Check as for ‘Mandrel Slip’, stage 2.

one fastener at a time. ➝ Incorrect gap between fastener head and nose jaws ➝ Set gap to 1.5mm - 3mm (

1

/16” -

1

/8”).

when loaded. See ‘Loading the Tool’, on page 6.

Engineered Fastening and Assembly Systems

type 0753

EN292 part 1 and part 2

ISO 8662 part 1

ISO 3744

ISO PREN792 part 14

Avdel UK Limited, Mundells, Welwyn Garden City, Herts, AL7 1QB

© Avdel ® Products mentioned and/or illustrated within this publication are subject to patent, design or copyright protection in many countries

following the provisions of the Machine Directive 98/37/EC

This box contains a power tool which is in conformity with Machines Directive

98/37/EC. The ‘Declaration of Conformity’ is contained within.

Welwyn Garden City - date of issue A. Seewraj

Product Engineering Manager - Automation Tools

Loading...

Loading...