E5

MAINTENANCE AND INSPECTION

CAUTION

The eective operating life of the AUD15 is a total of

25,000 hours of use or 5 years after the date of inspec-

tion by Azbil Corporation.

Take special care in handling the AUD15 to avoid im-

pact and shock.

When transporting or storing the AUD15, be sure to put

it in a secure packing box.

■ Maintenance and inspection of the AUD15 and

AUD120

● Flame failure test

To check that the ame safeguard control device works prop-

erly, do the ame failure test regularly.

During normal burner combustion, block the monitoring pipe

window so that there is no ame signal, or else cut o the fuel at the

source to extinguish the burner ame. Check that the ame failure

is detected and that the main valve and pilot valve are closed.

● Flame signal check

Regularly check the ame signal from the burner controller

that is used for batch operation. For the method of checking,

see the user’s manual for the burner controller.

● Check of the exterior

Check the following regularly.

•CheckthattheservicelifeoftheAUD15 has not expired. If it

has, replace the AUD15 with a new one.

•Checktheambienttemperature.ethermolabelcanbeused

to obtain a rough estimate of the ambient temperature. If the

temperature exceeds the specications, cool down the device.

•CheckthatthenutpackingandO-ringarenotdamaged.If

any damage is found, replace the damaged item.

•Checkthat thereisnocorrosion ordamageof the adapter

unit, socket unit, or lead wires. If a corroded or damaged

item is found, replace it with a new one.

•CheckthatAUD15 pins and pin base surface, and the AUD120

socket holes are not dirty. Replace any dirty component.

● How to clean the AUD15

Clean the light-receiving glass surface of the AUD15 using the

following procedure.

(1) Remove the AUD15 and AUD120 from the monitoring

pipe.

(2) Clean the light-receiving glass surface using a cotton swab

or the like.

(3) Remount the AUD15 and AUD120 on the monitoring pipe.

● How to replace the AUD15

(1) To avoid damage to the AUD15, hold the AUD120 socket

unit and pull it out carefully.

(2) Insert a new AUD15 into the socket (refer to “Inserting the

AUD15 into the AUD120” on page E2).

(3) Attach a new eective operation time label and expiration

date label.

Handling Precautions

•Do not touch the light-receiving glass surface.

•When mounting or removing the adapter unit, make

sure that the nut packing is not damaged.

•When mounting or removing the socket unit, make

sure that the O-ring is not damaged.

•If there is damage to the nut packing or O-ring, use

replacement parts from the AUD120 Packing Kit.

•When replacing the nut packing or O-ring, be sure not

to damage the O-ring grooves on the adapter unit

and socket unit.

SPECIFICATIONS

Item Specifications

Power supply Supplied by burner controller

Ambient

temperature

-20 to +105°C

Ambient

humidity

Lower than 90% RH at 40°C

Mass AUD120C120_ AUD120C121_

About 130g

(about 150g when con-

nected to AUD15)

About 140g

(about 160g when con-

nected to AUD15)

Insulation

resistance

At least 50MΩ with a 500Vdc megger

(Between each lead wire and socket metal, with AUD15

removed)

Protective

structure

IP65 (JIS C 0920 / IEC 60528, with piping connected, for

outside of AUD120)

Allowable

pressure

35kPa

Vibration

resistance

4.9 m/s

2

or lower

(10 to 55Hz, 2h each in X, Y, and Z directions)

Mounting nut G1/2 (connectable to R1/2)

Lead wires 18 AWG (approx. 1.2mm

2

)

Flame retardant cross-linked polyethylene insulated

cable

Length approx. 1800mm (blue, white)

Conduit Connection is not possible G1/2 (connectable to R1/2)

Standard and

extended dis-

tance of flame

signal wire

Standard: 600V vinyl insulated wire,

2.0 mm

2

(abbreviation: IV wire)

Extended distance: about 200m

Certification

Certificates

Directive File No. et.al Remarks

UL MH27717

CE*

GAD (2009/142/EC)

0063CN6671 with

RX-R4_C______

RoHS(2011/65/EU)

* CE marking appears to comply with RoHS.

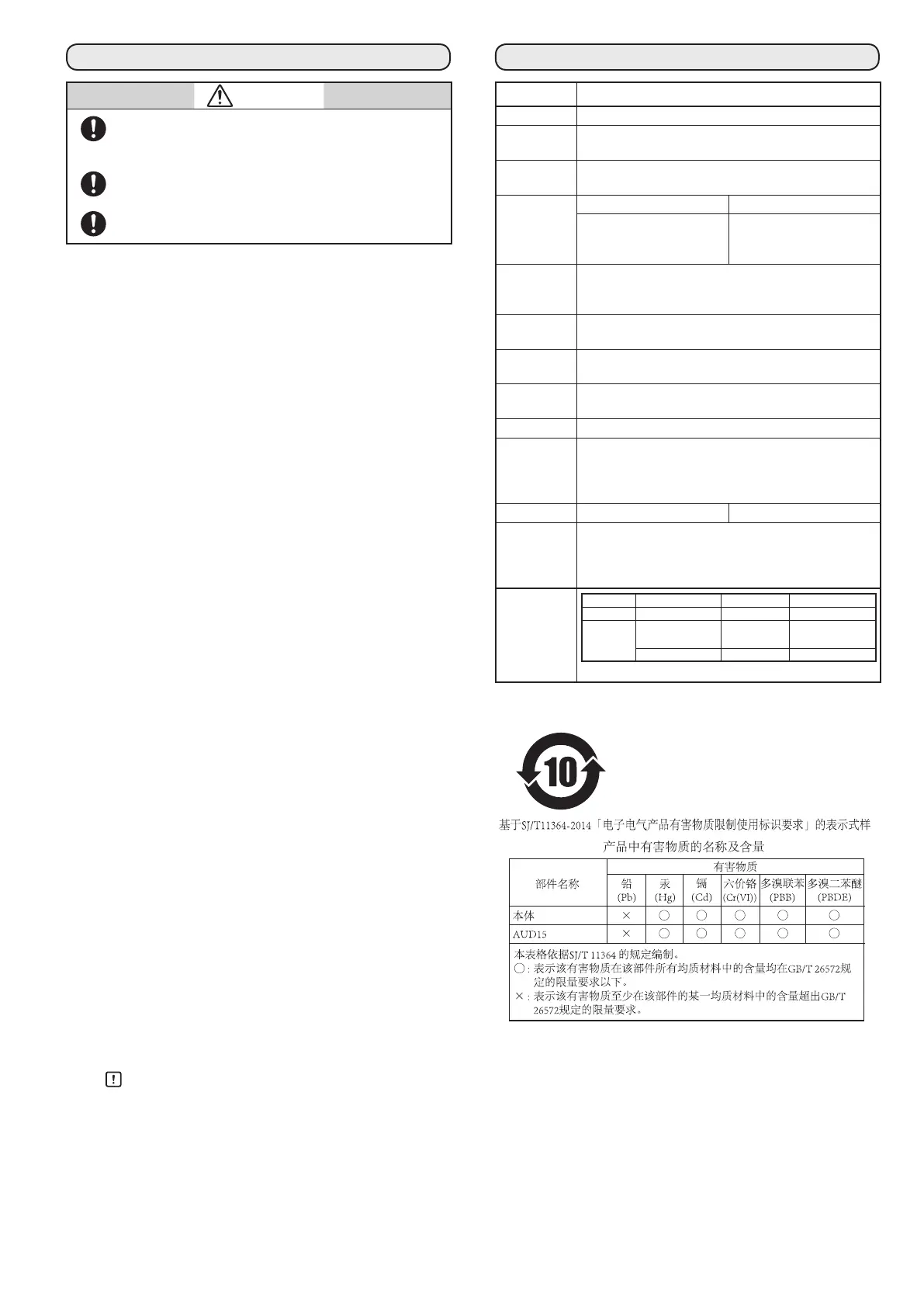

■ China RoHS

Loading...

Loading...