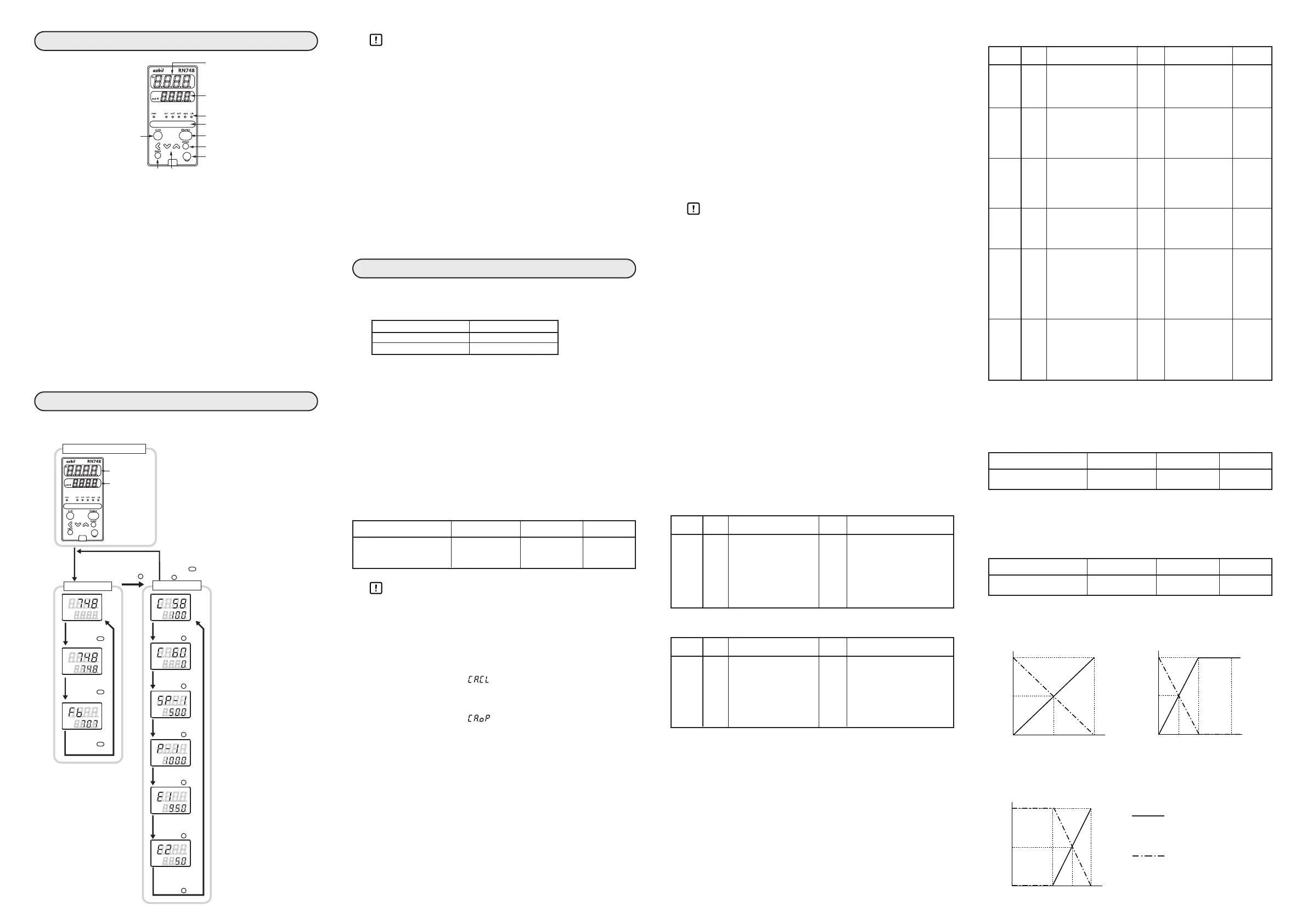

(1) Upper display: Displays input values (IN) or settings.

(2) Lower display: Displays manipulated variable (OUT), motor opening (MFB)

and other parameter values. When the display shows the

manipulated variable (OUT), the “out” lamp lights up.

(3) Mode indicator: man: Lights when in manual mode.

ev1 to ev3: Lights when event relays are ON.

opn • cls: Lights when the control output is ON.

(4) Multi-status

indicator: Through the combination of lighting conditions and lighting

status, 3 priority groups can be displayed.

(5) [a/m] key: Switches between AUTO and MANUAL mode when pushed

for 1s or more.

(6) [display] key: Used to change the display contents in the operation display

mode. Returns display from bank setup display to operation

display.

(7) <, , , key: Used for incrementing/decrementing numeric values and

performing arithmetic shift operations.

(8) [para] key: Switches the display.

(9) [enter] key: Used to set the setup values at the start of change and during

the change.

(10) Loader connector: Not available.

The following shows the key operation flow:

Handling Precautions

• When the [para] key is held down for 2 seconds or longer,

"LoC" will appear. This means you are at the lock setup

menu. Since there is no item to set up, press the [display] or

[a/m] key to return to the operation display.

● Setting example for position proportional control dead zone

Display "C58" on the upper display in the setup display mode. When the

[enter] key is pressed, the numerical value on the lower display will start to

flash. Move the digit and increase/decrese the numeric value by pressing

the [<][ ][ ] keys. When the [enter] key is pressed at the desired numeric

value, the flashing will stop and the data will be set.

● Setting example for motor auto adjustment

Display "C60" on the upper display in the setup display mode. When the

[enter] key is pressed, the numerical value on the lower display will start to

flash. Move the digit and increase/decrese the numeric value by pressing

the [<][ ][ ] keys. Set the value to "1" and press the [enter] key, and auto

adjust will start. The following items must be set up only when they are

changed from their defaults: center setting of the rotation angle,

proportional band setting, motor opening high/low limit event setting.

■ Selection of direct/reverse control action

You can select reverse or direct action of the RN748 by turning dital input 3

ON or OFF (DI3: between terminals 19 and 24) .

For the difference between direct and reverse action, see the figure in

"Setting example for the center of rotation and proportional band" (on

this page). Furthermore, you can switch between direct and reverse action

while running the RN748.

■ Adjustment and setting

Connect the RN748, controller, motor and other related devices correctly.

Then turn the power on and make adjustments and settings in the following

sequence:

(1) Do motor auto adjustment → (2) set the center of rotation angle → (3)

set the proportional band → (4) set the dead zone → (5) set the high/low

limit events for the motor opening.

The sections below show the details of each procedure.

■ Motor auto adjustment

Handling Precautions

• Be sure to execute auto adjustment. If the device is used

without doing auto adjustment, the motor may not operate

properly.

• Motor auto adjustment procedures

1. Set [C60: Motor auto adjustment] to 1 and press the [enter] key. If the C60

is already set to 1, press the [enter] key twice to perform this entry.

2. Motor auto adjustment then begins.

• The upper display shows and the relay on the CLOSE side is

turned ON.

• The motor rotates in the close direction, and the MFB count value is

written into [Fully closed adjustment value].

• The upper display shows , and the relay on the OPEN side is

turned ON.

• The motor rotates in the open direction, and the MFB count value is

shown on the lower display. When the counting stops, the fully open

adjustment is completed. This count value is then written into [Fully

open adjustment value]. Additionally, the period of time that has elapsed

from the fully closed position to the fully open position is written into

[Full opening time]. However, if this time is 240.0s or longer, this

parameter is set to 240.0s.

• When the motor auto adjustment has been completed, the basic display

screen will appear.

3. To cancel the adjustment, press the [display] key.

When motor auto adjustment starts, keys other than the [display] key,

which is used to cancel the adjustment, cannot be operated. If any of the

items below occurs, each value is returned to its default setting before

shipment and AL10 is shown as the troubleshooting process. AL10 is

cleared only when motor auto adjustment has been completed correctly or

when the power is reset.

• The count value between the fully closed position and fully open position

is less than 260.

• The fully closed count is greater than the fully open count.

• The period of time from the fully closed position to the fully open

position is less than 5s.

• The MFB burnout alarm (AL07) continues or occurs frequently.

• The time needed for the MFB count to stop exceeds 5min.

• The MFB or open/close relay has faulty wiring.

(However, not all faulty wiring can be detected as an error.)

Handling Precautions

• If the power to the RN748 is turned OFF during motor auto

adjustment of the position proportional control, motor auto

adjustment is cancelled when the power is turned ON again.

• Even if an AUTO/MANUAL mode changeover is made during

motor auto adjustment of the position proportional control, the

auto adjustment continues.

• If the control output (on the OPEN or CLOSE side) is forcibly

turned ON or OFF by the digital input 1 or 2 during auto

adjustment of the position proportional control, the auto

adjustment may continue. Even if it does not stop, the result

of adjustment is incorrect. It is necessary to repeat the

adjustment without forced ON/OFF.

• It is not possible to display the values saved for fully closed

adjustment value, fully open adjustment value, and full

opening time.

■ Motor auto adjustment operation

This unit has functions (AL07, AL10) that detect incorrect wiring to the

motor and MFB burnout or short-circuit. In the same manner as described

for direct wiring, the unit judges the reverse wiring as correct and does not

give any alarm. In addition, even if MFB burnout occurs, the operation

continues.

The tables below summarize characteristics of each wiring method when

motor auto adjustment is made (when [C60: Motor auto adjustment] is set to

[1: Start]). At this time, note that the motor is started from the fully closed

position (rotated fully counterclockwise). Numeric values shown in the

Lower display column of the tables are examples.

● Correct direct wiring

● Correct reverse wiring

● Alarm indications and causes due to incorrect wiring

■ Setting the center of rotation angle

When the center of the rotation angle is identical to the input (IN), the MV

(OUT) is 50%.

For details refer to:

Setting example "for the center of ratation and proportional band"

■ Setting the proportional band

When the input (IN) has changed by the amount of the proportional band

setting, the MV (OUT) changes in a range between 0 and 100%.

For details refer to:

Setting example "for the center of ratation and proportional band" below.

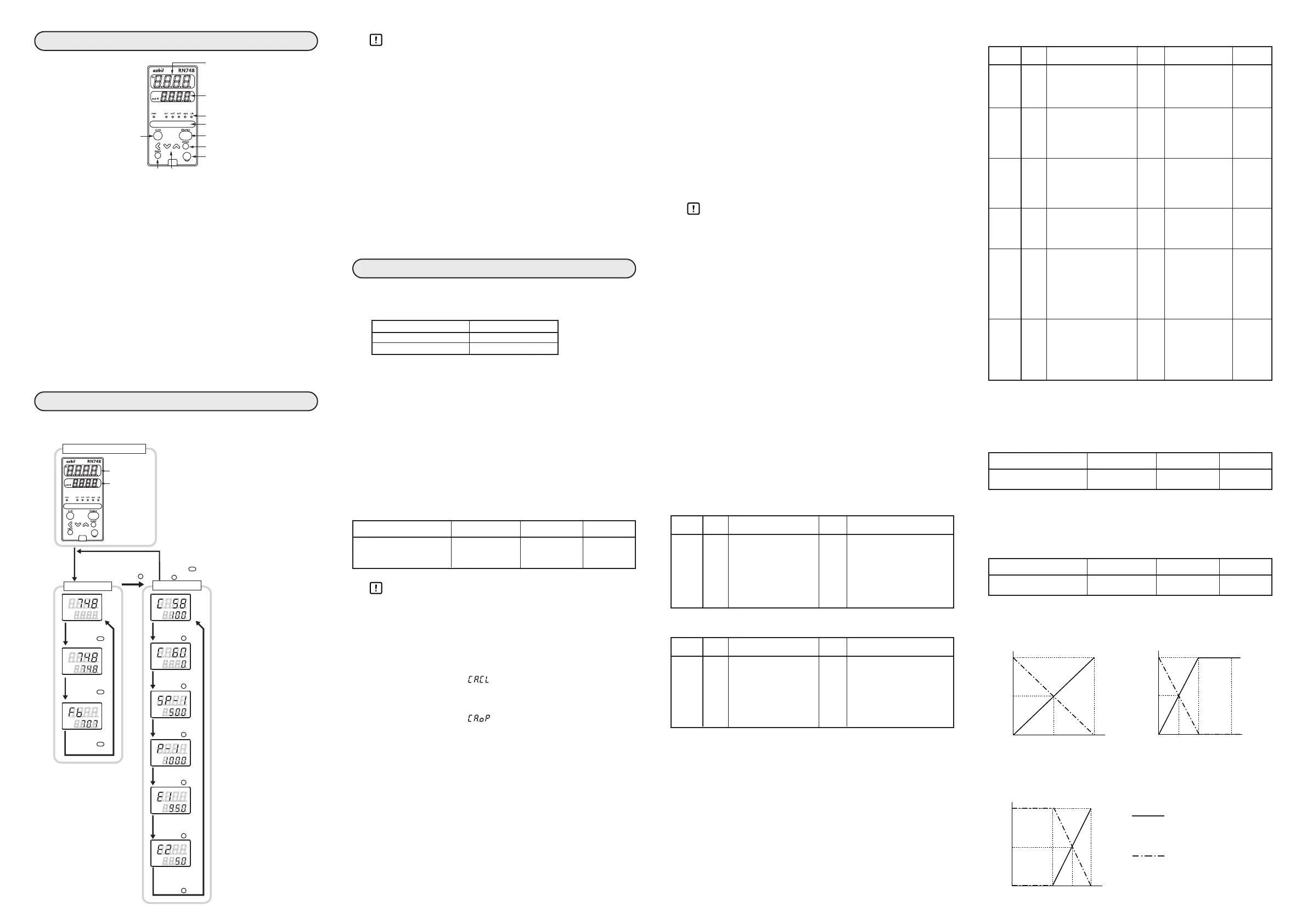

■ Setting example for the center of rotation and proportional band

1.

Center of rotation angle

: 50% (12mA) 2.

Center of rotation angle

: 25% (8mA)

Proportional band

: 100% (16mA)

Proportional band

: 50% (8mA)

3.

Center of rotation angle

: 75% (16mA)

Proportional band

: 50% (8mA)

<

<

<

<

<

<

or more.

Display when the power is turned ON.

E2

Operation preparation

Digital input 3 (DI3) Control action

OFF Direct action

ON Reverse action

Item Indication Contents Initial value

Motor auto adjustment

c60

0 : Stop 0

1 : Start

Upper display

Lit LED

Lower display

Motor motion

Remarks

CA.CL cls Shows a decrease CCW When the motor moves

like 2000 → 1500 and CCW with "cls" lit, motor

becomes stable. terminals 1 and 2 have

CA.OP opn Shows an increase CW direct wiring.

like 1500→3500 and

becomes stable.

Upper display

Lit LED

Lower display

Motor motion

Alarm indication Cause

CA.CL cls Increases and then CCW AL 10 G and Y

stops. are

CA.OP opn Decreases and then CW

connected

stops.

reversely.

CA.CL cls Increases and then CCW None. T and G

stops. However, the are

CA.OP opn Decreases and then CW MFB value does

connected

stops. not match the

reversely.

motor opening.

CA.CL cls Decrease or increase CCW AL 10 or none. T and Y

in unclear. are

CA.OP opn (Motor motion is CW

connected

changed before fully

reversely.

closed or opened.

CA.CL cls Increases and then CW AL 10 1 and 2

stops. are

CA.OP opn Decreases and then CCW

connected

stops.

reversely.

CA.CL cls Increases and then CW AL 10 1 and 2

stops.

connected

CA.OP opn Decreases and then CCW

reversely;

stops. T and G

are

connected

reversely.

CA.CL cls Decrease or increase CW AL 10 or none. 1 and 2

is unclear.

connected

CA.OP opn (Motor motion is CCW

reversely;

changed before fully T and G

closed or opened.)

connected

reversely.

↑

Upper display

Lit LED

Lower display

Motor motion

Remarks

CA.CL cls Shows a decrease like CW When the motor moves

3500 → 1500 and CW with 1 and 2 and

becomes stable. G and Y connected

CA.OP opn Shows an increae CCW reversely, with "cls" lit,

like 1500 → 3500 motor terminals 1 and 2

and becomes stable. have reverse wiring.

↑

↑

↑

↑

↑

↑

↑

Item Indication Contents Initial value

Center of rotation angle

SP

-1

0.0 to 100.0% 50.0%

Item Indication Contents Initial value

Center of rotation angle

P

-1

0.1 to 999.9% 100.0%

Loading...

Loading...