WWW.BALTIMOREAIRCOIL.COM

19

Detailed Component

Maintenance

Procedures

Fan Shaft Bearings

Inspection & Maintenance

Heat Transfer System

Fill & Drift Eliminator

Water Distribution System

Hot Water Basin

Operating Level

Inspection and Maintenance

Optional EASY CONNECT

®

Piping Arrangement

Water Level Control

Operating Level

Atdesignow,theoperatinglevelshouldnotbelessthan2inchesorgreaterthan6

inchesdeep.

Inspection and Maintenance

• Quarterly,ormoreoftenasrequired,removeanydirtordebriswhichmayclogthe

nozzles.Seasonally,cleanandushthehotwaterbasinwithfreshwater.

• Accesstothenozzlesrequiresremovalofthehotwaterbasincovers.

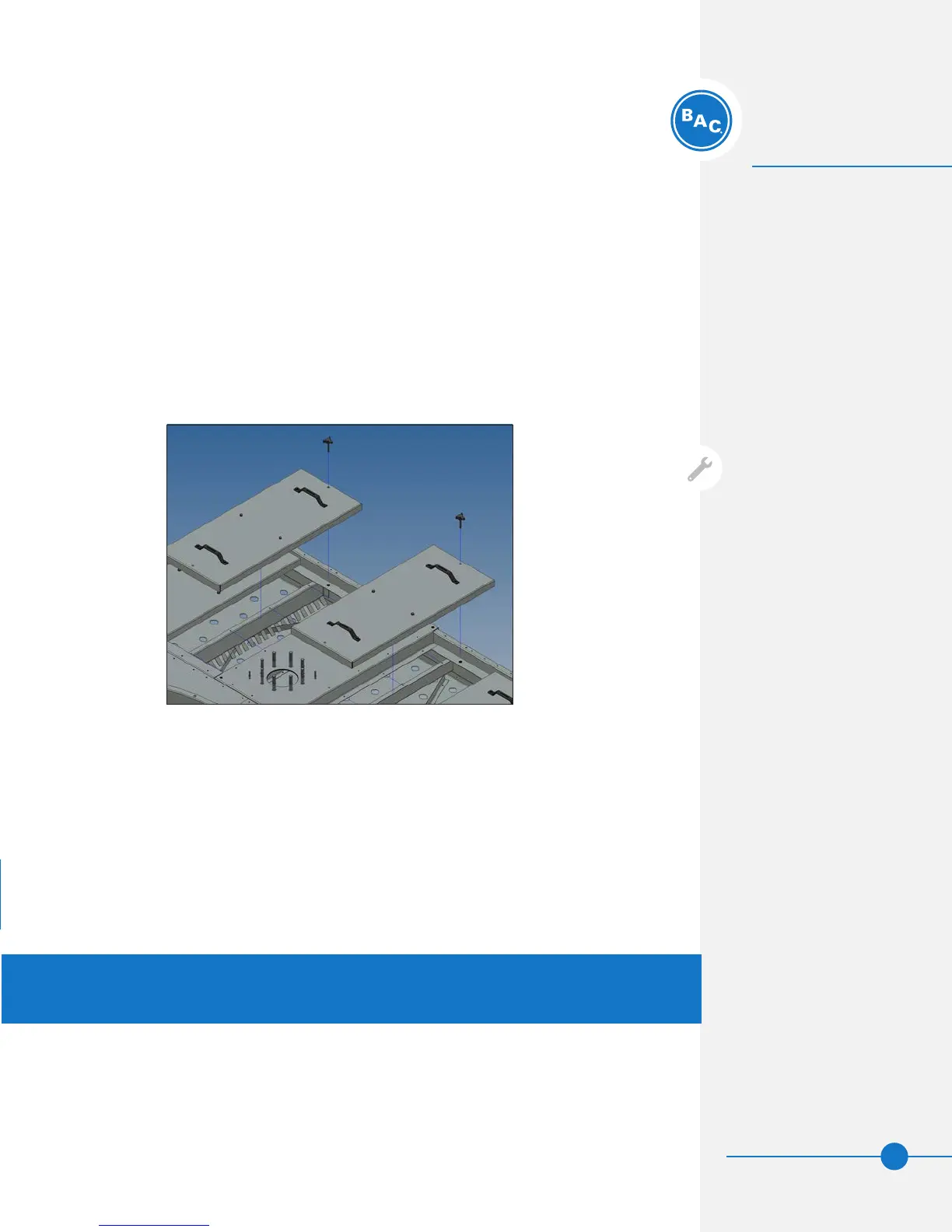

– Toremovethecoversturntheknobstoremovethethreadedstuds(Figure 6).Then,

liftthehotwaterbasincoversverticallybyusingtheattachedhandles.Oncethehot

waterbasincoversareremoved,thenozzlesmaybecleaned.

• Ifaccesstothenozzlesunderthepre-distributionchamberisrequired,remove

thehardwarethatfastensthetabbedbafes,thenremovethepanels.Retainthe

hardwaretore-installthetabbedbafes.

Optional EASY CONNECT

®

Piping Arrangement

TheSeries3000CoolingTowerhasanoptionalEASYCONNECT

®

PipingArrangement,

whichisequippedwithacappedcleanoutconnection.Thewatertobecooledentersthe

towerthroughasingleconnectionandpassesthroughtheEASYCONNECT

®

Chamber,

supplyingwatertobothhotwaterbasins.SeeFigure 7, page 30.

Water Level Control

There are two types of water level controls used on Series 3000 Cooling Towers:

• Mechanicalmake-upvalveassembly

• Optionalelectricwaterlevelcontrolpackage

TheSeries3000watermake-upvalveassemblyislocatedattheconnectionendofthe

unit.

ATTENTION: Do not use steam or

high pressure water to clean PVC

eliminators or materials other than

steel.

Figure 6. Hot Water Basin Cover Removal

Loading...

Loading...