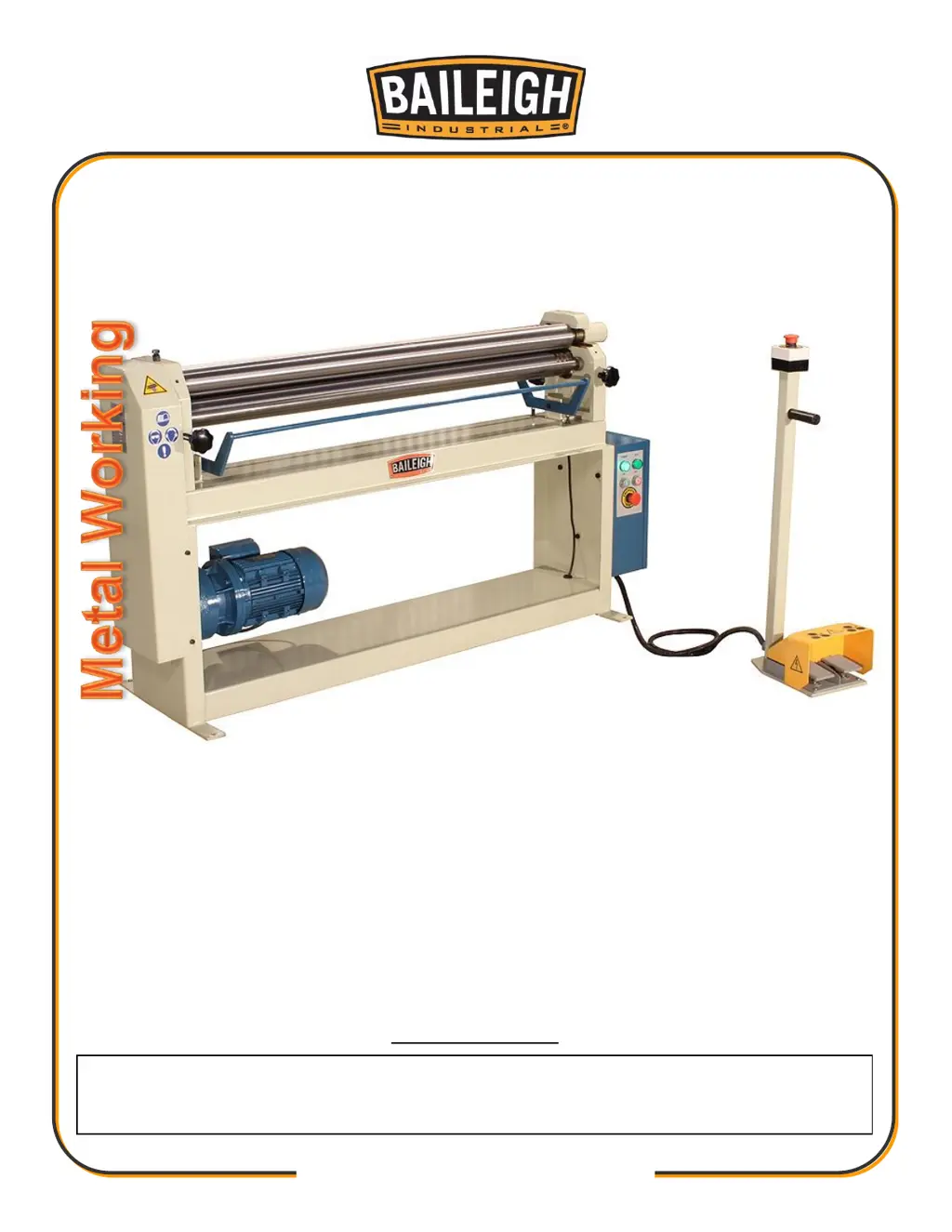

Why does my Baileigh Industrial Equipment slip roll create cones instead of cylinders?

- NNicole MoraAug 7, 2025

If your slip roll is creating cones instead of cylinders, it could be due to several reasons: * The rolls might not be parallel. Adjust the rear roll to ensure it is parallel to the top roll. * Excessive pressure might be applied to one spot. Try reducing the radius and make the bend in several passes. * The material sheet might be dirty, or the roll could be damaged. Clean the material and polish any nicks in the roller.