Do you have a question about the Baker SterilGARD e3 SG404 and is the answer not in the manual?

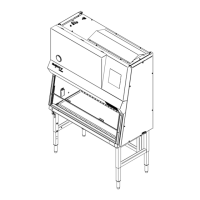

Defines the SterilGARD® e³ as a Class II, Type A2 Biological Safety Cabinet.

Lists standards the cabinet meets and is tested to, including UL, CSA, and NSF/ANSI.

Describes the negative pressure plenums surrounding the work area for strength and seals.

Explains the blower's automatic compensation for filter pressure drop to maintain airflow.

Details the manual balancing damper for adjusting down flow and exhaust/intake imbalances.

Describes the HEPA filters, their 99.99% efficiency, and ULPA option.

Explains front accessibility for filter removal via an access panel.

Describes the seamless stainless steel interior with a smooth radius for cleaning.

Explains the purpose of air slots for cabinet integrity at critical transitions.

Describes the function of towel guards in preventing material intake into the blower.

Details the corrosion-resistant, recessed stainless steel work surface reducing reflection.

Describes the stainless steel drain pan with a smooth radius and drain valve.

Explains the UV-resistant safety glass view screen and its counterbalanced operation.

Specifies the standard 8" and optional 10"/12" view screen access opening sizes.

Describes the external fluorescent lamp providing illumination at the work surface.

Explains the solid-state electronic ballasts for improved reliability and efficiency.

Details the GFCI protection for outlets on 115V AC/60Hz cabinets.

Describes petcock and plugged penetrations for services on side walls.

Mentions audible and visual alarms for unsafe conditions like sash or power faults.

Explains programmable timers for lights, outlets, and UV light operation.

Describes the EPDM armrest and its bypass function when the screen is closed.

Explains the telescoping plenum for even clamping force on HEPA filter frames.

Notes the integrated motor and blower assembly designed to minimize vibration.

Describes the analog gauge displaying the cabinet's negative static pressure.

Explains the function and location of cable ports for introducing cables and tubes.

Describes the mode for reduced airflow and energy consumption when the cabinet is not used.

Details the alarm for power outages or microprocessor/controller faults.

Describes the adjustable legs for three fixed height adjustments and levelers.

Mentions the option for an intravenous (IV) Bar to facilitate hanging materials.

Describes the optional UV light and its minimum intensity at the work surface.

Notes availability of seismic anchoring plates with or without California OSHPD pre-approval.

Explains the exhaust connection for safe exhaust to building systems.

Details the touch screen display for cabinet controls, monitoring, and alarms.

Lists options for external status connections to HVAC systems.

Overviews the controls and indicators on the front electrical panel.

Explains the pushbutton switch for the cabinet blower and its indicator light.

Details the operation of the fluorescent light and its interlock with the blower.

Describes the pushbutton switch for work area outlets and circuit protection.

Explains the operation and interlocks of the UV light, warning of hazards.

Describes the pushbutton to mute audible alarms and the flashing LED indicator.

Categorizes and explains potential hazardous conditions indicated by alarms.

Explains the alarm for unsafe sash positions, including delay and muting.

Details the alarm for power outages or microprocessor/controller faults.

Describes the alarm for simultaneous activation of both sash position sensors.

Explains the alarm for low exhaust airflow impacting capture air intake.

Details programming for lights, outlets, and UV light in 15 min or 1 hour increments.

Outlines the steps for programming 15-minute timer increments for device shutoff.

Outlines the steps for programming 1-hour timer increments for device shutoff.

Explains the function and placement of cable ports for introducing cables and tubes safely.

Further details on cable port usage and precautions when removing items.

Provides a step-by-step guide for initiating cabinet operation.

Suggests basic work practices for safe and effective cabinet operation.

Advises on placement of equipment to minimize airflow disruption and turbulence.

Outlines procedures for dealing with spills and the importance of safety plans.

Provides instructions for cleaning and disinfecting the cabinet's stainless steel surfaces.

Provides instructions for basic cleaning with water, detergent, or mild cleaner.

Details the purpose and methods of disinfection with recommended agents.

Provides instructions for cleaning the drain pan, assuming contamination.

Explains the necessity and methods of cabinet decontamination before maintenance.

Describes the HEPA filter construction, function, delicate nature, and efficiency.

Outlines the terms and conditions of the product warranty and remedies.

| Type | Class II, Type A2 Biological Safety Cabinet |

|---|---|

| Filter Type | HEPA |

| HEPA Filter Efficiency | 99.99% at 0.3 microns |

| Electrical Requirements | 115V, 60Hz, 10A |

| UV Light | Optional |

| Interior Work Surface | Stainless Steel |

| Inflow Velocity | 105 feet per minute |

| Downflow Velocity | 0.25 m/s |

| Noise Level | 63 dBA |

| Motor | ECM |

Loading...

Loading...