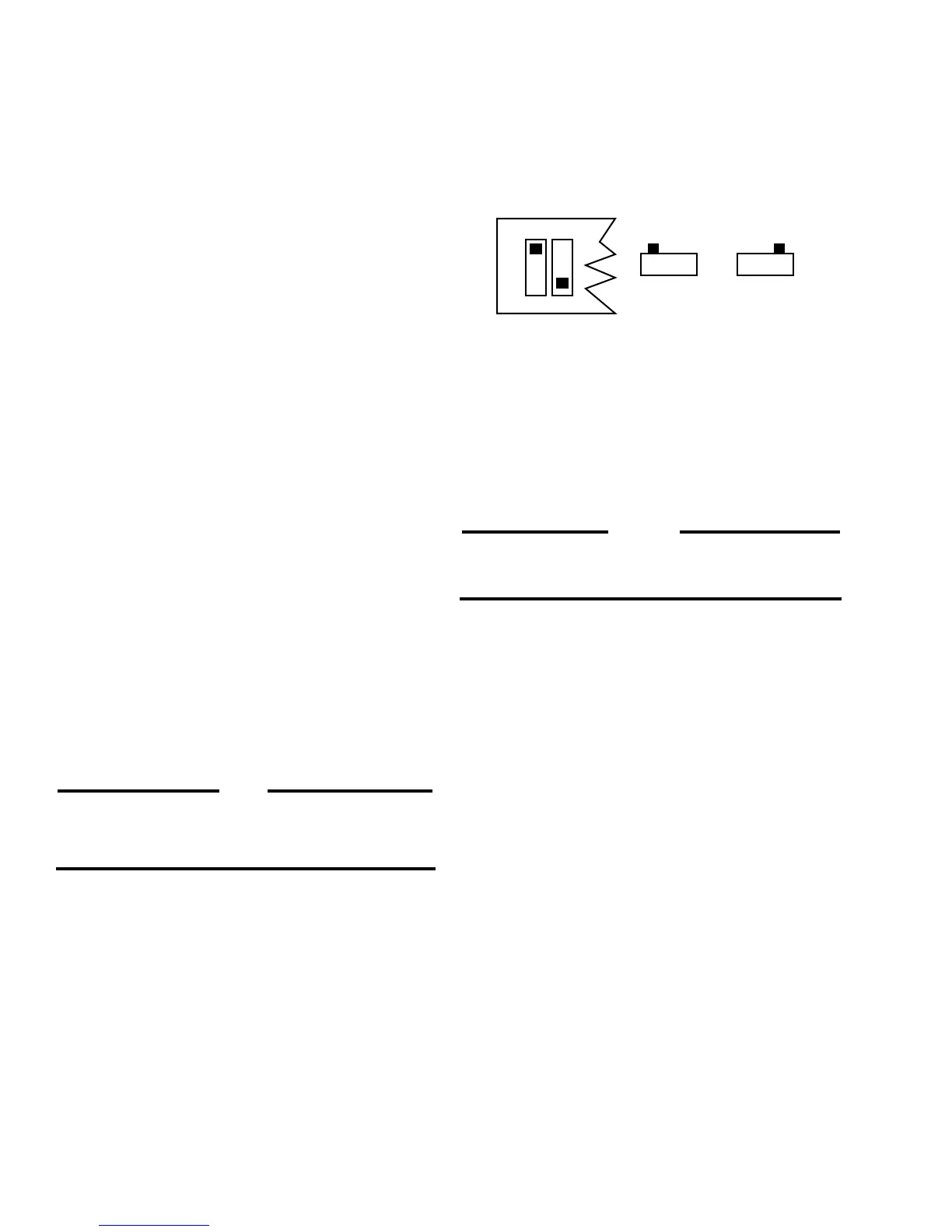

Side View

"On"

ON OFF

Side View

"Off"

OFFON

O

N

O

F

F

Top View

S1 S2

5.5 PROPER PROCEDURES FOR SETTING SWITCHES S1

AND S2

Question: How do I know if the switches in the dual-in-line

packages are correctly set as far as being in the OFF position

or the ON position?

Answer: The drawings above should clarify any confusion

about switch settings. The easiest way to set the switches is to

apply pressure with a small pointed object until the switch clicks

into position.

CAUTION

As a safety measure, the engine should be equipped with

an independent overspeed shutdown device in the event

of failure which may render the governor inoperative.

10

NOTE

For some diesel engines, better operation may be

obtained by placing SW1 in "ON" position. If

difficulty is experienced in "OFF" position, try SW1

ON and recalibrate.

5.3 ALL CONTROLLERS WITH REVISION J AND ABOVE

HAVE SWITCHES S1 AND S2

These units have two new features now added to the DYN1

1065X series controllers. They are:

5.3.1 Two response ranges, for matching either the diesel or

gas engine dynamics.

• Set S1 to the OFF position for diesel engine applications.

• Set S1 to the ON position for gas/gasoline engine

applications.

5.3.2 Two actuator selections, so the same controller can be

used on the DYNA 8000, DYNA 8200 or DYNA 8400 actuator.*

• Set S2 to the OFF position when using a DYNA 8000

actuator.

• Set S2 to the ON position when using a DYNA 8200 or DYNA

8400 actuator.

5.4. GENERAL INFORMATION ON S1 AND S2

• Switch S1 selects one of two integrating rate ranges. The

diesel version integrates at twice the rate of the gas version

• Switch S2 selects the point at which actuator coil current

level causes the integrator limit to be actuated. This level

is nominally 6.3 amperes for the DYNA 8000 and 7.3 am-

peres for the DYNA 8200 and 8400 actuator.

* DYNA 8000 -- DYNC 11020 Series

DYNA 8200 -- DYNC 12000 Series

DYNA 8400 -- DYNC 14800 Series

These actuators do not have a potentiometer feedback

transducer.

Loading...

Loading...