=

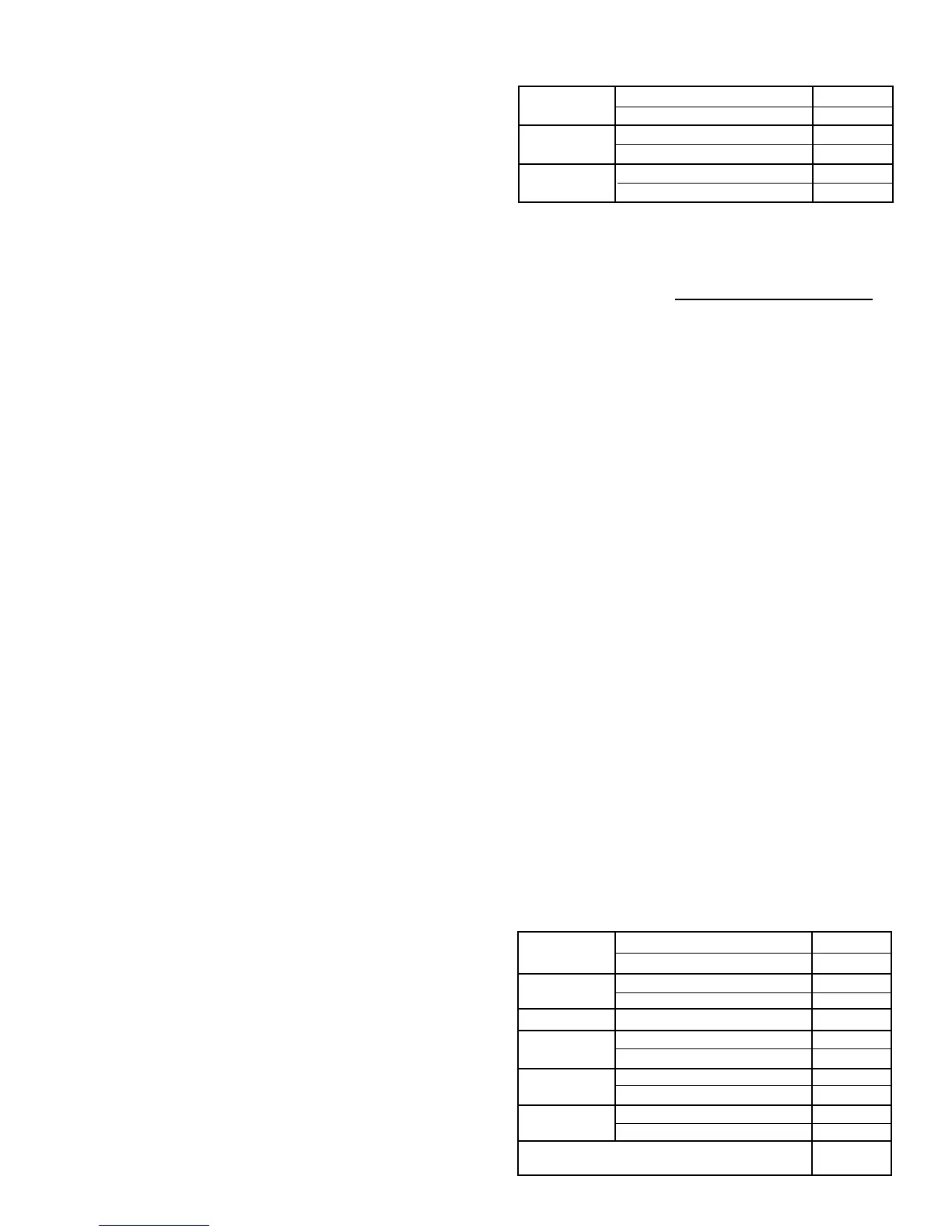

Input Signal

Frequency in Hertz

3

2.1.10 DYNA 8000 CONTROLLER

Nominal Quiescent Current 80 mA

Maximum Amperes @ Stall 13 amps

Nominal Quiescent Current 80 mA

Maximum Amperes @ Stall 13 amps

Kilograms 0.863

Pounds 1.9

Output Current

@ 24 VDC

Weight

Output Current

@ 12 VDC

2.1.11 DYNA 8000 CONTROLLER

INPUT SIGNAL FREQUENCY

Engine RPM x Number of Gear

Teeth on Flywheel

60 Seconds

Select controller for the correct input signal frequency range

generated by the magnetic pickup at the maximum engine

operated (RPM) speed.

2.1.12 AVAILABLE CONTROLLER MODELS

Controllers: Speed Input Signal Frequency

• DYN1-10652-000-0-12/24 250 - 1200 Hz

• DYN1-10653-000-0-12/24 1200 - 2500 Hz

• DYN1-10654-000-0-12/24 2500 - 5000 Hz

• DYN1-10656-000-0-12/24 5000 - 9500 Hz

• DYN1-10682-000-0-12/24 250 - 1200 Hz

• DYN1-10683-000-0-12/24 1200 - 2500 Hz

• DYN1-10684-000-0-12/24 2500 - 5000 Hz

• DYN1-10686-000-0-12/24 5000 - 9500 Hz

2.2. DYNA 8000 & DYNA 8000 UL APPROVAL,

HAZARDOUS DUTY, CLASS 1, DIVISION 2, GROUP D

ACTUATOR SPECIFICATIONS

2.2.1 Operating Voltage: 12 VDC or 25 VDC ±20%

2.2.2 Ambient Operating Temperature:

-65 to +255°F (-55 to +125°C).

2.2.3 Sealed Unit: Oil, water and dust tight.

2.2.4 Connection: Terminal strip or "MS" Connector.

2.2.5 Mechanical Vibration: 5 to 500 Hz, Curve F, per

MIL-STD. 810D, Method 514-2.

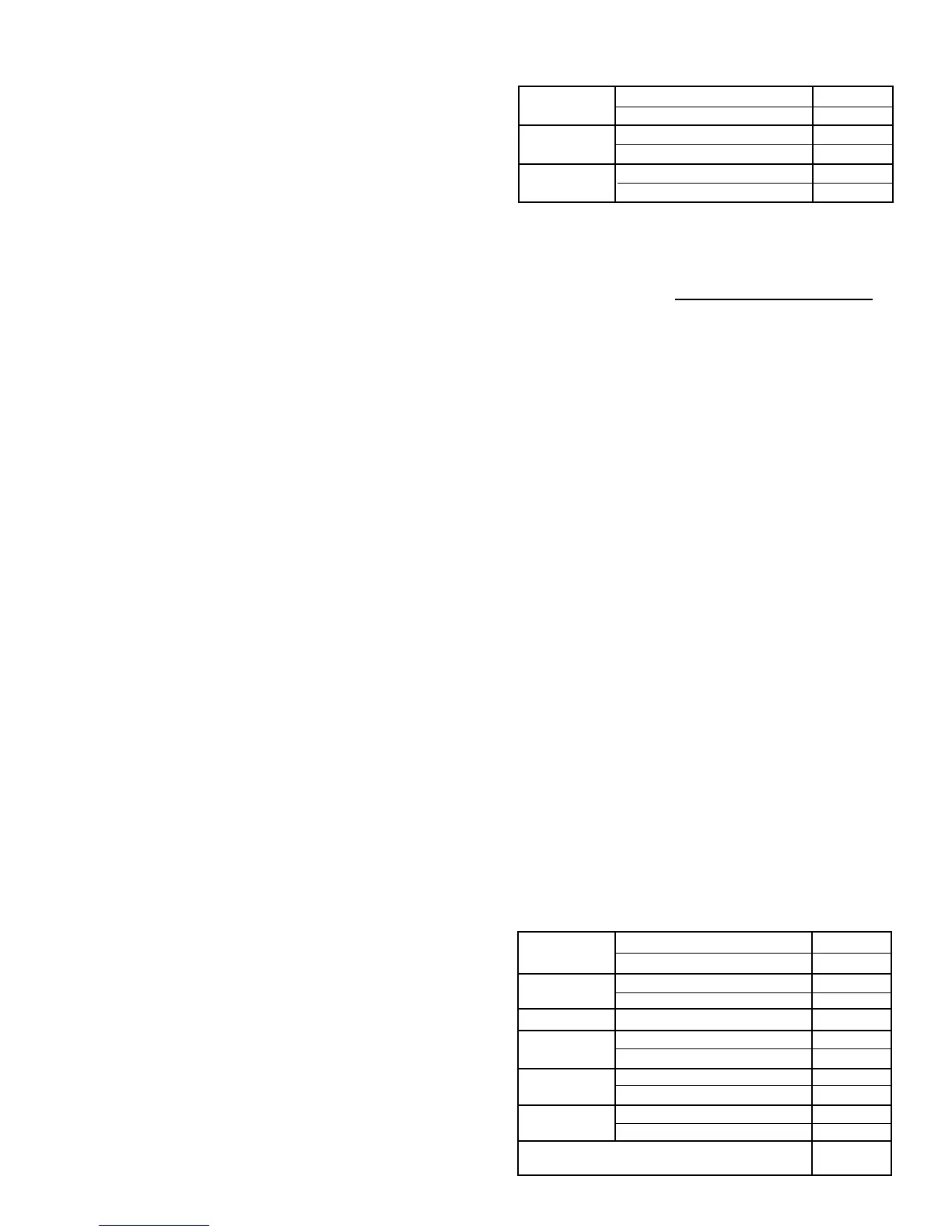

2.2.6 DYNA 8000 ACTUATORS

Joules 1.2

Foot-Pounds 0.9

Newton-Meters 1.4

Pound-Foot 1.0

Rotary 35°

Kilograms 5

Pounds 11.0

Maximum Amperes @ Stall 12.5

Nominal Steady State Amperes 3.5

Maximum Amperes @ Stall 9.5

Nominal Steady State Amperes 1.5

Nominal Response Time for 63% of Stroke

(Seconds)

Current @

12 VDC

Current @

24 VDC

Torque

Output

Weight

Work

0.030

1. GENERAL INFORMATION

1.1 INTRODUCTION

The DYNA 8000, DYNA 8200 and DYNA 8400 governor system

provides an engine governor for speed and power control of

piston and gas turbine engines or steam and water turbines.

The actuator is a simple, proportional, electric solenoid having

a sliding armature whose magnetic force is proportional to input

coil current. The armature glides on anti-friction bearings and is

balanced between the force of its return spring and the mag-

netic force, thus providing a hysteresis-free linear movement.

The linear motion is converted to an output shaft rotation by a

crank arm.

The hazardous duty DYNA 8000 and DYNA 8400 actuators

provide units that are UL listed for Class I, Division 2, Group D,

hazardous duty applications that are often encountered in the

petroleum or chemical industries. The hazardous duty actua-

tors can be used to provide an engine governor for speed and

power control of piston and gas turbine engines.

1.2 TYPICAL APPLICATIONS

Typical applications are speed governing, remote throttle con-

trol, generator sets, power carts and pump set applications.

1.3 STANDARD FEATURES

• All electric

• All engine compatible

• Mounts in any position

• Engine mounted (actuator only)

• High reliability due to few moving parts

• Proportional actuator

• No hydraulic or oil lines

• No special maintenance

• Spring returns output shaft to minimum position on removal

of power or loss of magnetic pickup signal

• Precise repeatability

2. SPECIFICATIONS

2.1 CONTROLLER SPECIFICATIONS

2.1.1 Operating Voltage: 12 VDC or 24 VDC ±20%

2.1.2 Ambient Operating Temperature:

-40 to +180°F (-40 to +85°C).

2.1.3 Temperature Stability: Better than ±0.5% over a

temperature range of -40 to +167°F (-40 to +75°C).

2.1.4 Steady State Speed Band: ±0.25%

2.1.5 Adjustments: Speed, Gain, Integral, and Droop.

2.1.6 Circuit Boards: Boards are covered with a heavy

conformal coating for moisture and vibration protection.

2.1.7 Connection: Terminal strip.

2.1.8 Mechanical Vibration: Withstands the following vibra-

tion without failure of degraded performance: 0.06 inch double

amplitude at 5 to 18 Hz; 1 G at 18 to 30 Hz; 0.02 inch double

amplitude at 30 to 48 Hz; 2.5 G's at 48 to 70 Hz.

2.1.9 The same DYN1-1065X or DYN1-1068X Series can be

used on a DYNA 8000, DYNA 8200 or DYNA 8400 actuator.

The DYN1-1068X governor control box provides a wider range

of adjustment than the DYN1-1065X. The DYN1-1068X can be

used where maximum performance is desired or for some

engines which are possibly more difficult to control.

Loading...

Loading...