Instruction, Use and Maintenance Manual

EN-IST-BBZK-0418

Risk of

stainless steel

corrosion

Risk of damage

elastomers

8 Cleaning

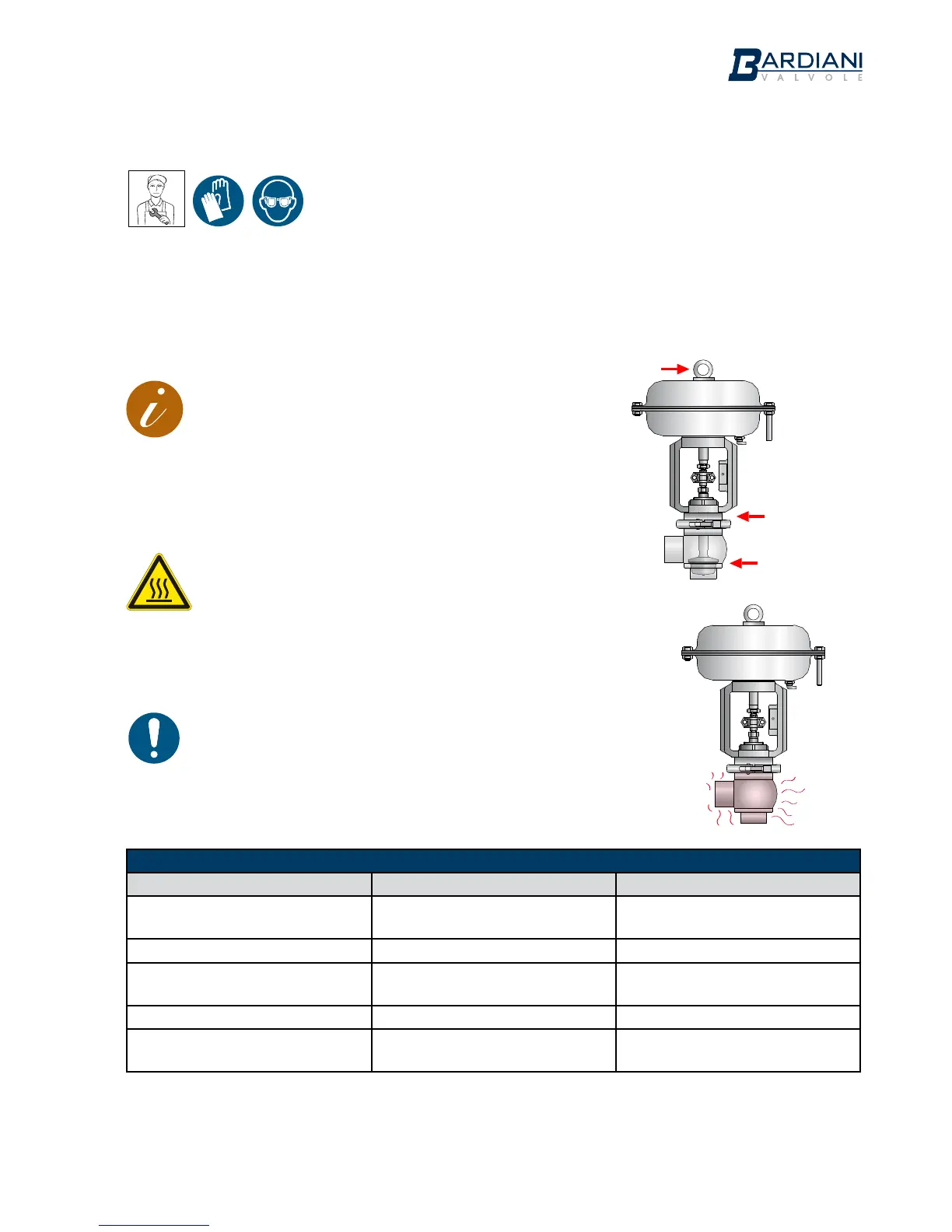

1. VALVE CLEANING WITH DETERGENTS:

The system in which the valve is installed must be cleaned by expert

personnel in observance of the following:

- Abide by the indicated detergent concentration values;

- Observe the instructions provided by the detergent manufacturer.

- Always wear protective safety glasses and gloves.

IMPORTANT!

- Accurately dose detergents to avoid excessive concentration;

- Always rinse thoroughly with clean water after washing.

- Check compatibility of valve materials.

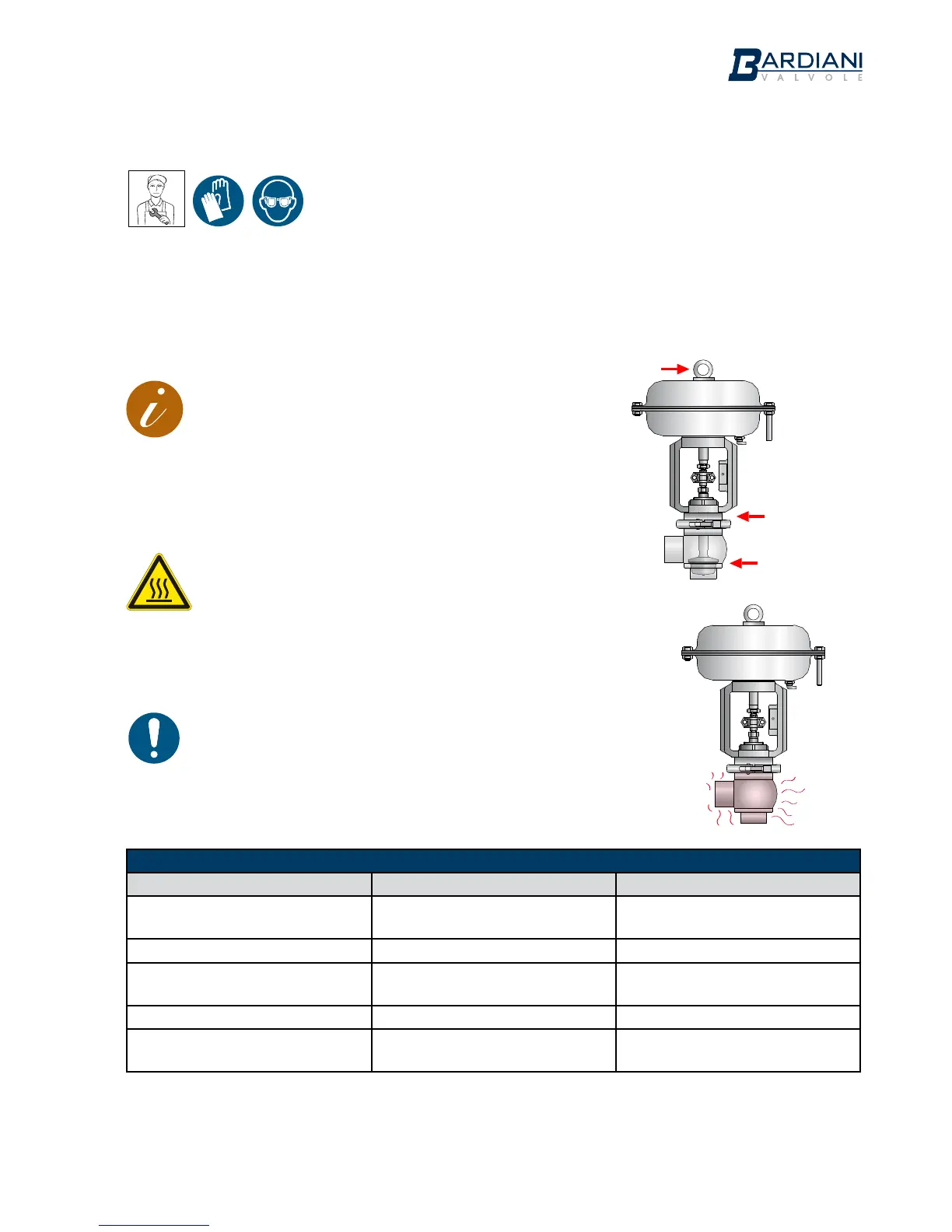

CAUTION!

Burns hazard. The valves and piping may be very hot. Wear protective

gloves

WARNING

After installing a new or serviced valve, perform an internal washing

cycle before using the piping for food liquids. If it there has been any

welding work, passivation treatment must be carried out.

EXAMPLE OF INTERNAL WASHING CYCLE (CIP)

Phases Temperature °C Washing product

Initial rinse Environment Chlorine- and chloride-free

water

Washing 70 °C Caustic soda (NaOH) at 1%

Intermediate rinse Environment Chlorine- and chloride-free

water

Washing 70 °C Nitric acid (HNO3) at 0.5%

End rinse Environment Chlorine- and chloride-free

water

Recommended washing product velocity = 2m/s

15

Loading...

Loading...