Do you have a question about the barfield 1811NG and is the answer not in the manual?

Overview of the manual's purpose and content structure.

Details the items included with the test set, such as manuals and labels.

Explains the required recertification process and its importance for accuracy.

Information on downloading and using the mobile app for remote control.

Guidance on checking for and applying software updates to the test set.

Lists aircraft applications for which the test set is a suitable substitute.

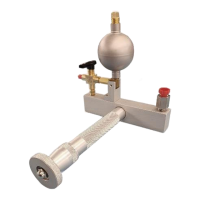

Specifies the primary purpose and applications of the 1811NG Pitot-Static Test Set.

Outlines the physical, environmental, conformity, performance, and display unit specifications.

Provides guidance on connecting and operating the test set with aircraft systems.

Contact information and procedures for obtaining technical support for the 1811NG.

Specifies the acceptable input power voltage and frequency ranges for the test set.

Describes the power entry module and its components, including safety notes.

Details the operating and storage environmental conditions for the test set.

Instructions for unpacking, checking contents, and assembling the test set and its components.

Procedures for safely grounding the test set chassis to the aircraft or test instrument.

Details the power supply cable and its specifications for connecting the test set.

Information on keeping intake and exhaust vents clear and the humid air exhaust port.

Specifies the Pitot (Pt) and Static (Ps) port connections using AN4 fittings.

Identifies and describes the front panel switches, ports, and display components.

Guidelines for positioning the test set safely for operation and quick disconnection.

Lists included items and items not included with the test set package.

Recommendations for familiarizing with the interface before connecting to aircraft systems.

Describes the sequence and information displayed during the test set's power-on process.

Explains the 2-channel (Ps & Pt) and 1-channel (Pt-Only) operating modes.

Details how to interpret the status display for mode, limits, and altitude correction.

Explains the structure and navigation of the test set's graphical user interface.

Instructions on configuring display format and selecting units of measure.

Overview of the two leak testing methods: Leak Rate Timer and ATP Leak Test.

Explains the Pneumatic Control Module (PCM) operation and its two-channel control.

Steps to prepare the test set and hoses for leak testing before use.

Procedures for performing leak tests on the test set and hoses themselves.

How to record and subtract test set/hose leakage from aircraft test results.

Essential checks and connections before performing aircraft system tests.

Procedures for leak testing combined ALT & CAS using traditional or ATP methods.

Detailed steps for testing the aircraft's static pressure system.

Detailed steps for testing the aircraft's pitot pressure system.

Instructions for simultaneously testing both pitot and static systems.

How to perform tests with constant Calibrated Airspeed or constant Mach.

Procedure for testing airspeed switches using the Nudge feature.

Steps to connect the test set and prepare for EPR transmitter testing.

Methods for performing EPR testing using aeronautical units or EPR mode.

Steps to safely shut down the test set and return it to ambient pressure.

Recommendations for inspecting the test set upon receipt and retaining packaging.

Guidelines for properly packing and preparing the test set for reshipment.

Instructions for storing the test set in a cool, dry place with desiccant.

Manufacturer's recommendation against user maintenance and for contacting approved facilities.

Routine visual inspections and checks for moisture or foreign matter.

Steps for recording error codes or noting issues during unit malfunction.

Information on the annual calibration interval and the importance of qualified service.

Step-by-step guide to connect the test set to an Android device via Wi-Fi.

Step-by-step guide to connect the test set to an Apple device via Wi-Fi.

Instructions for activating the Cabin Pressure Mode feature on the test set.

Procedures for operating the test set in Cabin Pressure Mode during aircraft testing.

Steps to access and configure the Inlet Barrier Filter (IBF) system mode.

| Description | Digital Pressure Gauge |

|---|---|

| Type | Digital |

| Liquid Filled | No |

| Connection | 1/4" NPT |

| Dial Size | Not applicable |

| Temperature Range | -10°C to 50°C |