Do you have a question about the barfield 1811G and is the answer not in the manual?

Provides manufacturer contact details for inquiries, support, and comments.

Highlights warranty validation, user registration, and update notifications.

Details the history of changes and updates made to the manual.

Guides users on maintenance, repair, and obtaining Return Maintenance Authorization (RMA).

Explains the manual's purpose and scope for the Pitot-Static Test Set.

Lists items accompanying the test set, including identification labels and warranty cards.

Covers recertification periods and recommendations for test set maintenance.

Defines the manual's objective for the Pitot-Static Test Set.

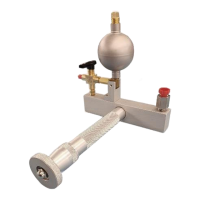

Details the test set's purpose, compliance, and general features.

Lists physical dimensions, weight, instruments, and pump specifications.

Describes the carrying case and panel layout with item callouts.

Introduces the operation section and provides pneumatic diagrams.

Explains how to use hand pumps and external sources for pressure/vacuum.

Details the preliminary setup steps before performing tests.

Provides procedures for checking the test set for leaks (Pitot and Static).

Outlines procedures for testing aircraft static systems.

Details procedures for testing aircraft pitot systems.

Describes tests for combined pitot and static aircraft systems.

Procedure for testing Machmeters using the test set.

Procedure for testing Engine Pressure Ratio (EPR) instruments.

Procedure for testing manifold pressure gauges.

Details tests for pressure units within a specified range.

Details tests for vacuum units within a specified range.

Instructions for safely shutting down the test set and aircraft connections.

Instructions for receiving and inspecting the test set upon arrival.

Guidelines for properly configuring the test set for shipping.

Steps for properly storing the test set to maintain its condition.

Details required inspections at different intervals (e.g., each use, 6 months, 12 months).

Ensures correction cards are updated and calibration dates are recorded.

Details performance requirements for pressure sensitive altimeters.

Details performance requirements for pitot static type airspeed indicators.

Details performance requirements for pressure actuated vertical speed indicators.

| Type | Analog Pressure Gauge |

|---|---|

| Case Material | Stainless Steel |

| Liquid Filled | Yes |

| Temperature Range | -40 to 150°F |

| Accuracy | ±1% Full Scale |

| Connection | 1/4 inch NPT |

Loading...

Loading...