1150-003

INVERTER MULTI-PROCESS WELDER KIT

16

NOTICE: If Wire Spool can spin freely, Wingnut is too loose. This will cause

the welding wire to unravel and unspool which can cause tangling and feeding

problems.

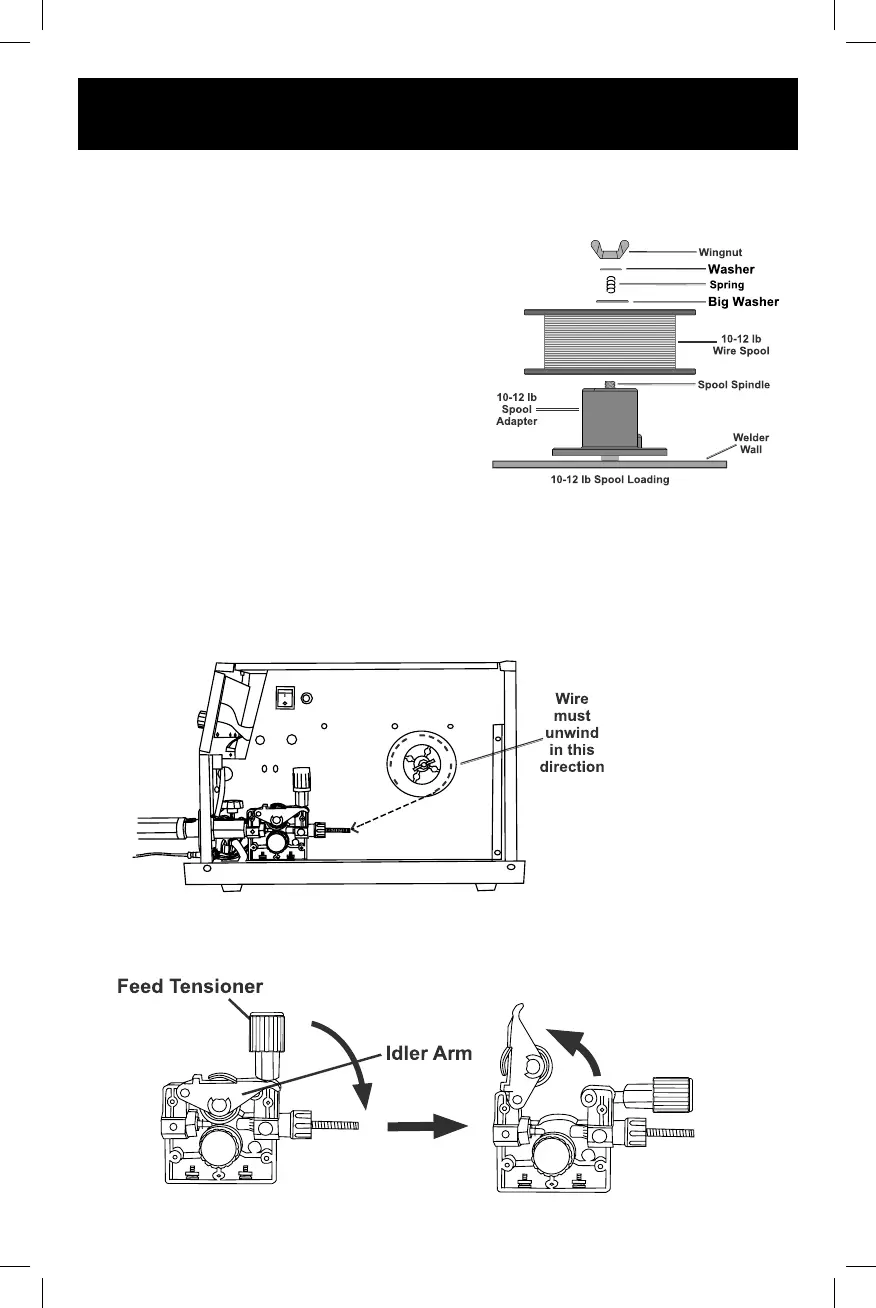

6. 10-12 pound Wire Spool installation: Remove

the Wingnut, spring and washers. If replacing

a Spool, remove the old Spool and all

remaining wire from the liners.

7. Place the Spool Adapter over the Spool

Spindle and against the Spool Brake Pad as

illustrated.

8. Place the new Wire Spool over the Adapter

and line up pin on Adapter with hole in Spool.

to prevent wire feed problems, set the Spool

so that it will unwind clockwise.

9. Replace the Spacer over the Spool Spindle

and secure Spool in place with the Wingnut.

NOTICE: This will cause the welding wire to unravel and unspool which can cause

tangling and feeding problems.

10. Screw the Spool Knob into the Spool Adapter.

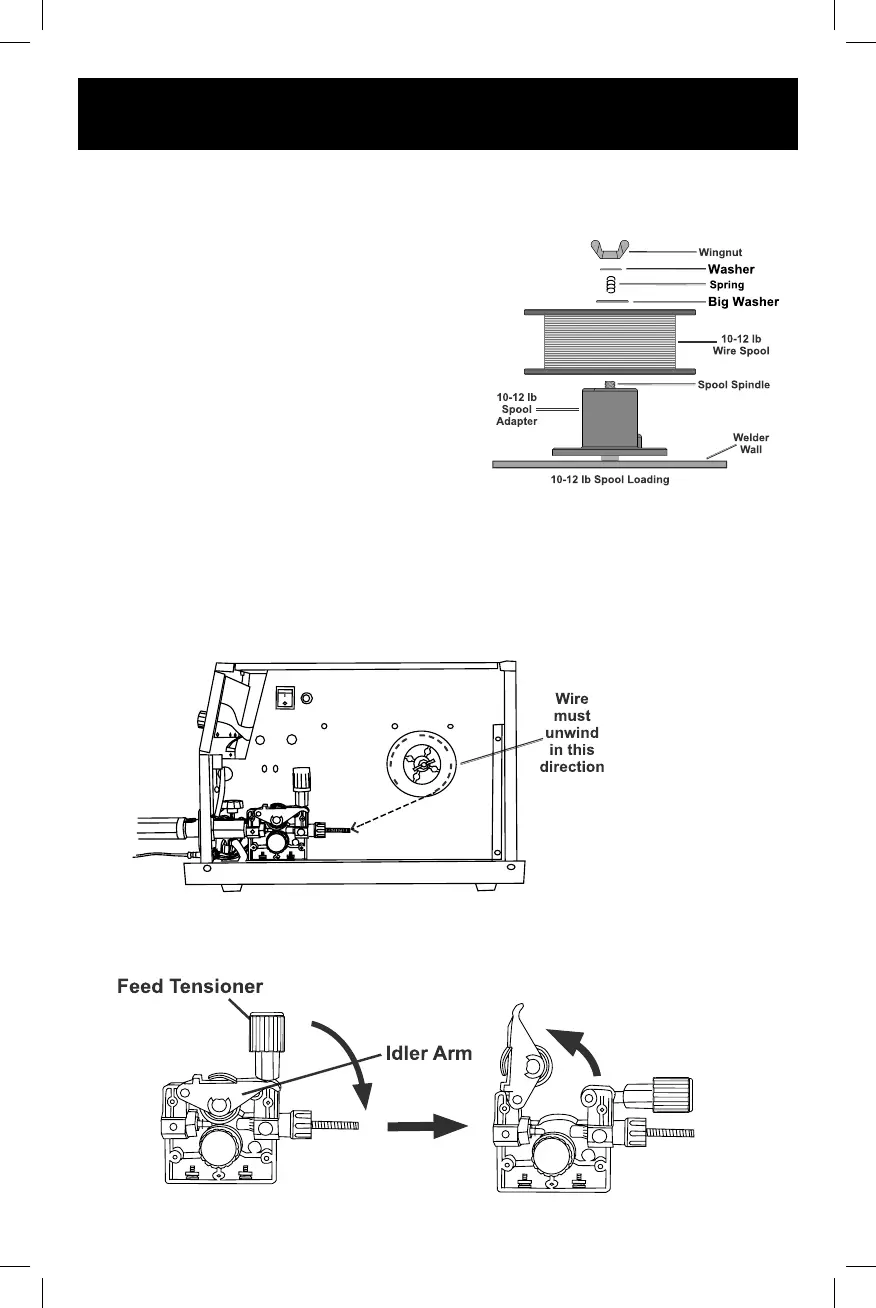

11. Turn the Feed Tensioner knob counterclockwise to loosen it enough to pull it

down to remove tension. The spring-loaded Idler Arm will move up as shown.

Loading...

Loading...