1150-003

INVERTER MULTI-PROCESS WELDER KIT

20

IMPORTANT

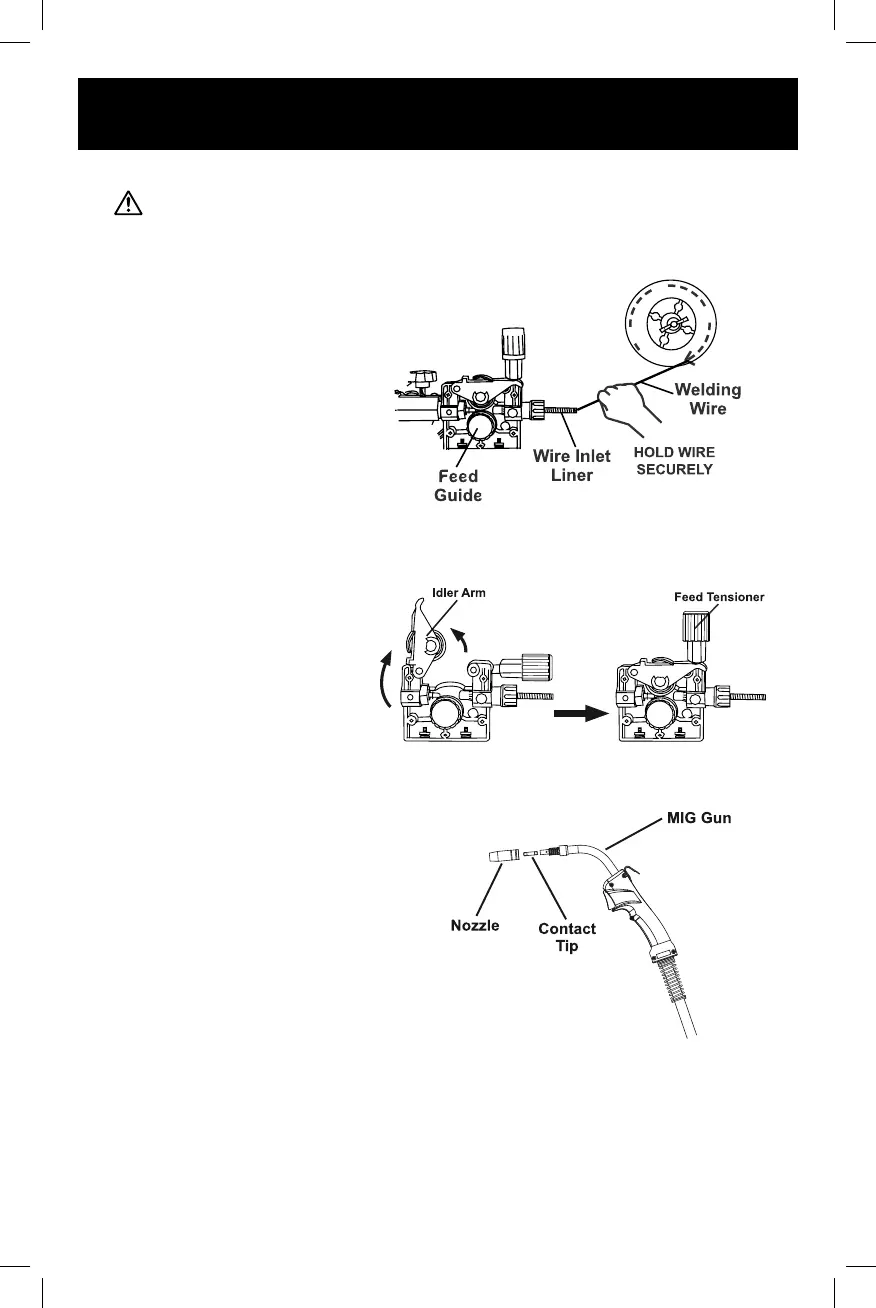

Securely hold onto the end of the welding wire and keep tension on it during

the following steps. If this is not done, the welding wire will unravel and

unspool which can cause tangling and feeding problems.

18. Cut o all bent and crimped

wire. The cut end must have

no burrs or sharp edges; cut

again if needed.

19. Keep tension on the wire and

guide at least 12 inches of

wire into the Wire Inlet Liner

and Feed Guide.

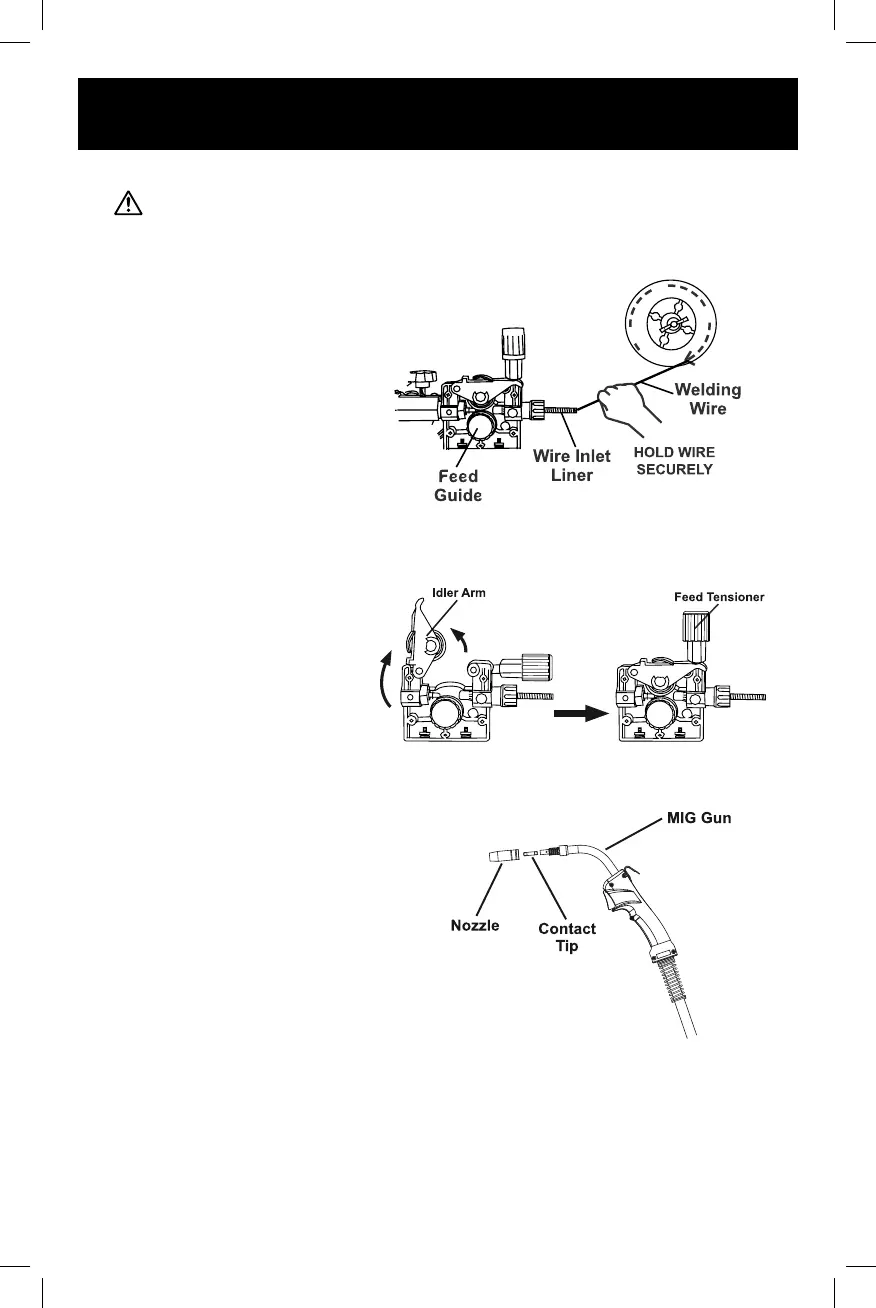

20. Make sure the welding wire

is resting in the groove of the

Feed Roller, then push the

wire Idler Arm down, and

swing the Feed Tensioner up

to latch it across the tip of

the arm. After the wire is held

by the Tensioner, you may

release it.

NOTE: The tension should be

3– 5 for solid wire and 2 – 3 for

flux-cored wire. Too much force

on flux-cored wire will crush it

and may cause feeding issues.

21. Pull the Nozzle to remove it.

22. Unscrew the Contact Tip

counterclockwise and remove.

23. Lay the MIG Gun Cable out in a straight

line so that the welding wire moves

through it easily. Leave the cover open,

so that the feed mechanism can be

observed.

IMPORTANT Stainless steel wire is less flexible than other

welding wire. therefore, it is more dicult to feed through the

liner and gun. it is especially important to keep the gun cable

straight while feeding stainless steel wire.

Loading...

Loading...