1150-003

INVERTER MULTI-PROCESS WELDER KIT

26

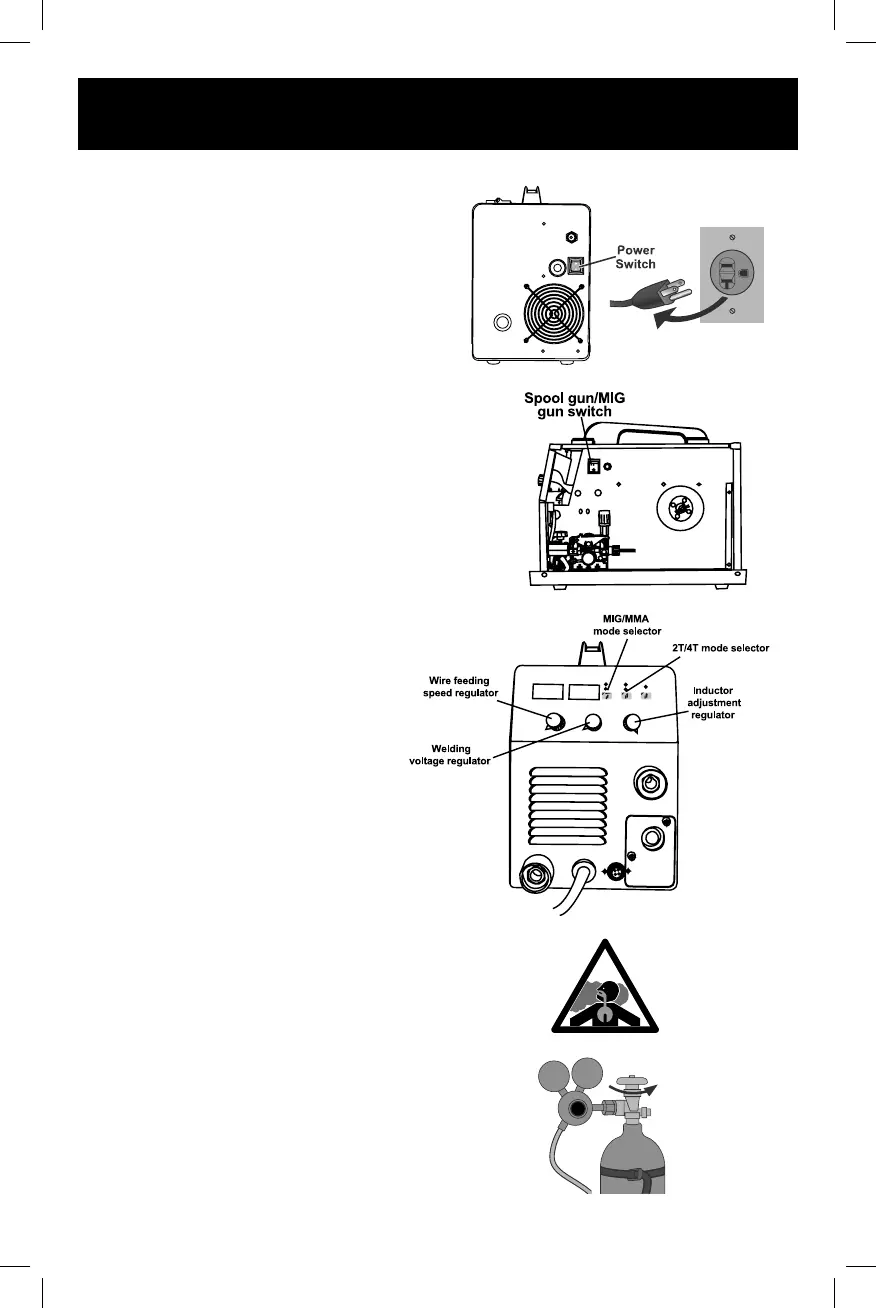

4. Turn the Power Switch to the OFF

position, then plug the Power Cord into

a properly grounded, GFCI protected

120 VAC (20 amp rated) or 230 VAC

receptacle that matches the plug. The

circuit must be equipped with delayed

action-type circuit breaker or fuses.

5. Set MIG Gun down on nonconductive,

nonflammable surface away from any

grounded objects.

6. Turn the Power Switch ON.

7. Press the Spool gun/MIG gun switch to

MIG gun position.

SETTING

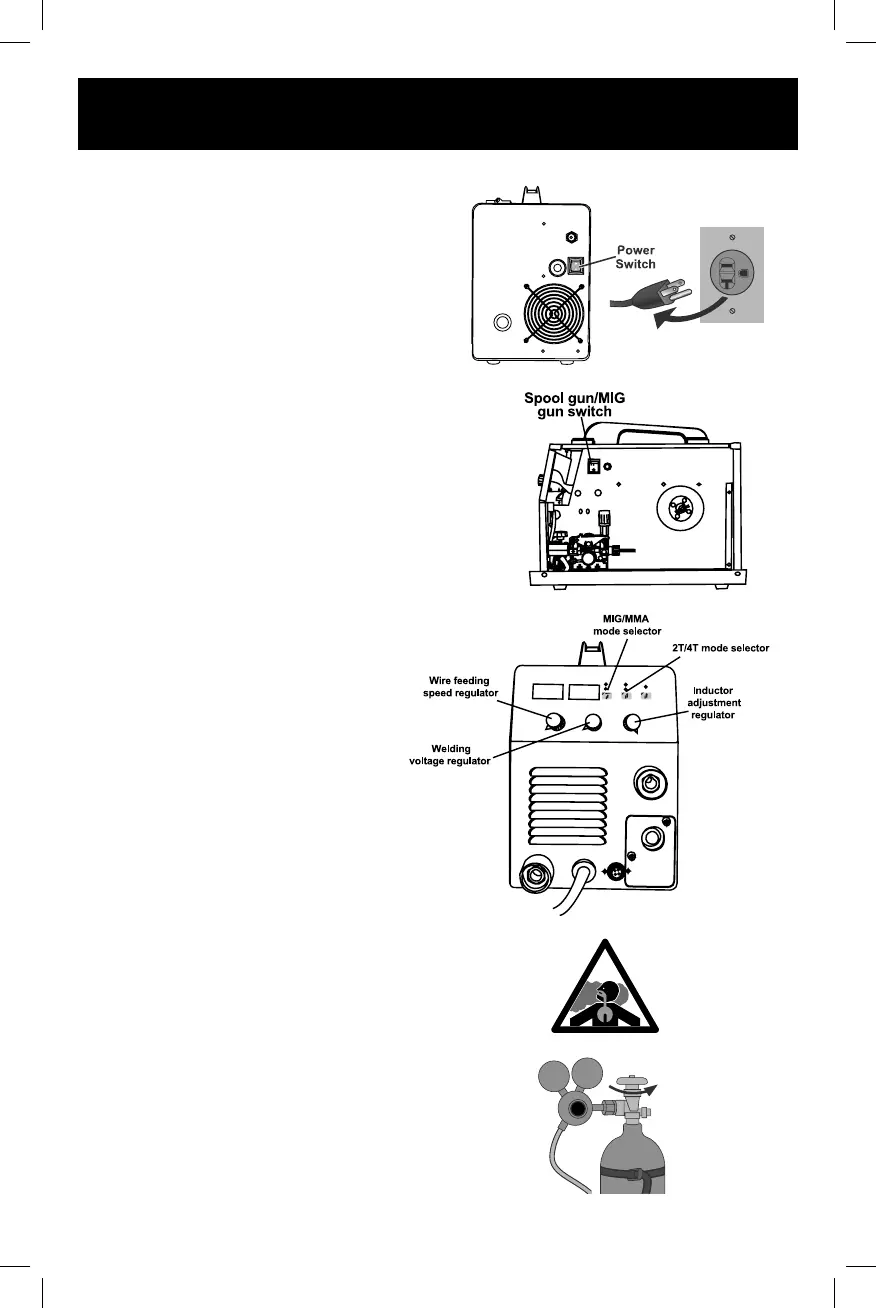

1. Press the setting up button to select MIG.

2. Turn the welding voltage regulator to

adjust voltage.

3. Turn the wire feeding speed regulator to

adjust the wire feed speed.

4. Turn the Inductor adjustment regulator

to adjust length of arc. Increase for

more fluid puddle and flatter bead.

Decease for colder puddle.

5. Press the 2T/4T mode selector to

select work mode.

2T Mode: Press the gun/torch trigger to

weld and release to stop. It's usually

used under spot welding/section

welding application.

4T Mode: Press and release the gun/torch

trigger to start, weld without holding

the trigger on and stop by pressing and

releasing the trigger again.

This is particularly useful when doing

continuously welding jobs.

GAS SHIELDED, SOLID-CORE WIRE ONLY

Loading...

Loading...