13

BENDIX

®

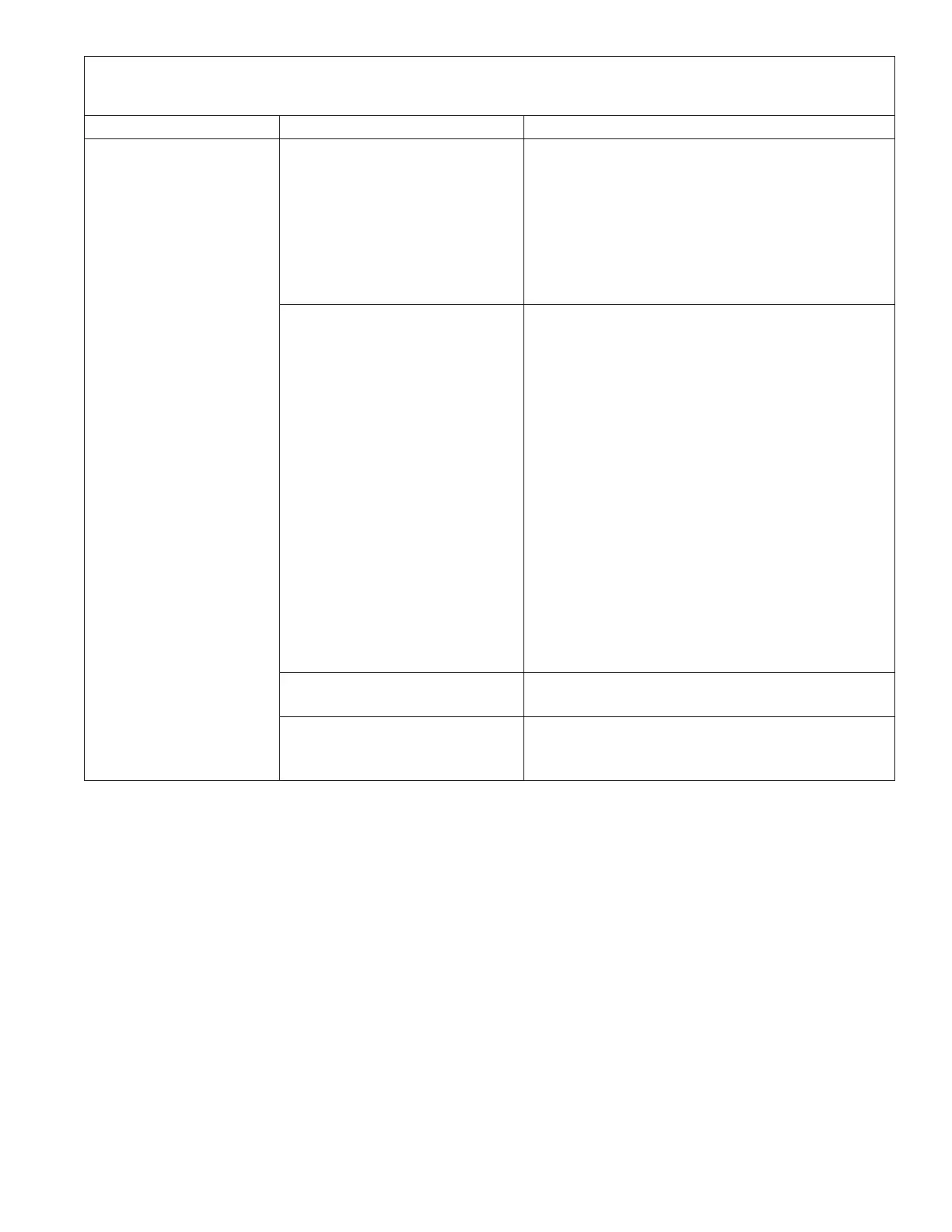

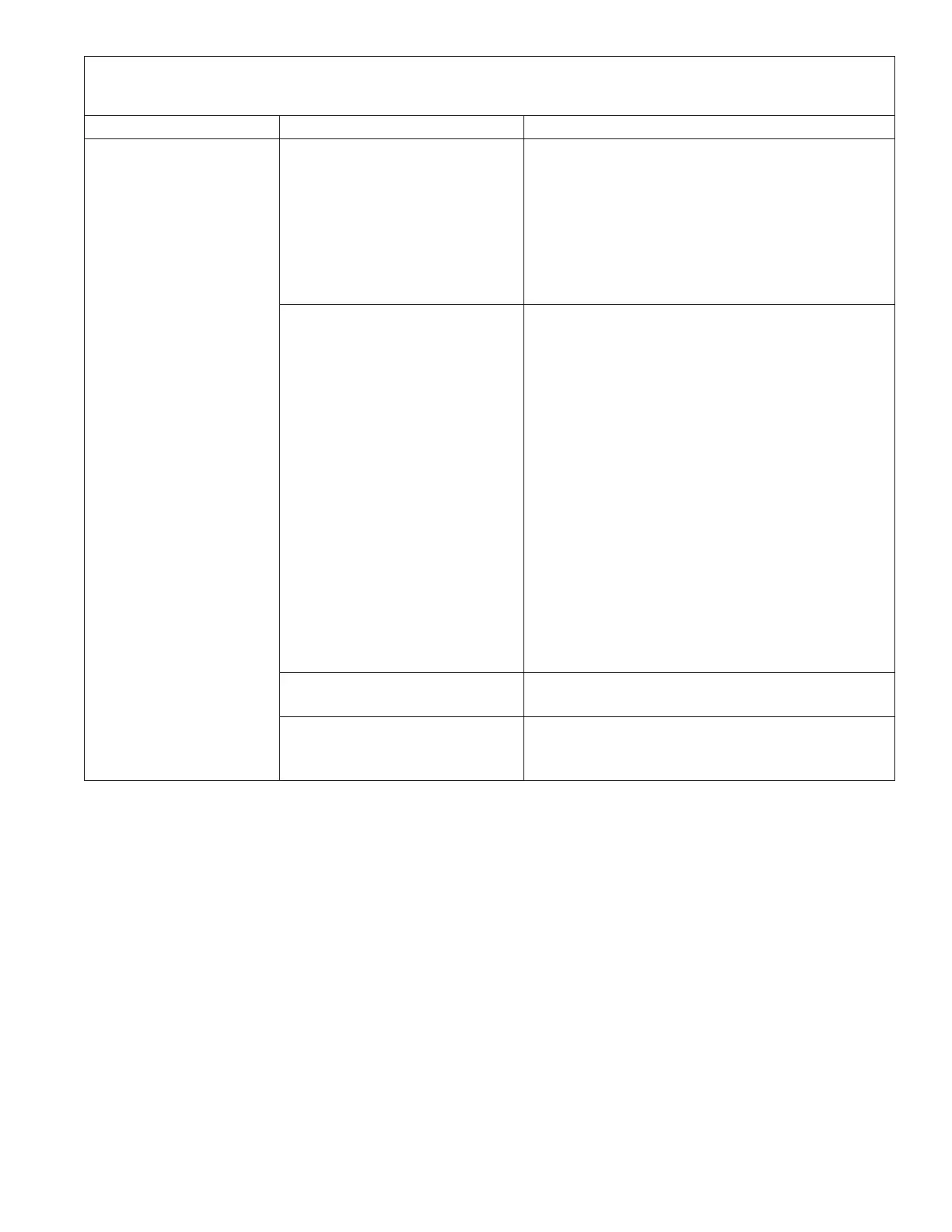

AD-9si

®

AIR DRYER

TROUBLESHOOTING CHART

SYMPTOM CAUSE REMEDY

1. Dryer is constantly “cycling”

or purging.

A. Excessive system leakage. A. Test for excessive system leakage. Allowable leakage observed

at dash gauge:

- Single vehicle - 1 psi/minute.

- Tractor trailer - 3 psi/minute.

Using a soap solution, test the vehicle for leakage at the

fittings, drain valves, system valves, and any accessories (i.e.

air suspension). Repair or replace as necessary and retest the

system.

B. Defective delivery check valve. B. Build the system pressure to governor cut-out. Wait 1 minute for

completion of purge cycle. Using a soap solution at the exhaust

of the purge valve, leakage should not exceed a 1 inch bubble

in less than 5 seconds.

If a rapid loss of pressure is found, the following procedure will

determine if the delivery check valve is malfunctioning:

Build the system pressure to governor cut-out and allow a full

minute for the normal dryer purge cycle to empty the purge

reservoir. Switch off the engine and apply and release the brakes

multiple times so that the system pressure reaches governor cut-

in. The purge valve will return to its closed position. Carefully

remove the air dryer cartridge using a strap wrench and then

test for air leaking through the center of the threaded boss by

applying a soap solution to the area. Replace the delivery check

valve if there is excessive leakage (exceeding a 1 inch bubble

in 5 seconds).

Re-grease the seal on the air dryer cartridge before reinstalling.

C. Defective governor. C. Check governor at both “cut-in” and “cut-out” position for

proper pressures and excessive leakage at the exhaust.

D. Compressor unloader mechanism

leaking excessively.

D. Remove the air strainer, or fitting, from the compressor inlet

cavity. With the compressor unloaded, check for unloader piston

leakage. Slight leakage is permissible.

Loading...

Loading...