8

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended

warranty may be voided if intrusive maintenance is

performed during this period. Purge valve and governor

maintenance is permissible during the warranty period

only when using a genuine Bendix

®

AD-9si

®

purge valve

kit or governor kit.

Because no two vehicles operate under identical

conditions, maintenance and maintenance intervals will

vary. Experience is a valuable guide in determining the

best maintenance interval for any one particular operation.

RESERVOIR DRAINING

Per the guidelines shown in Table 2, check for moisture in

the air brake system by opening reservoir drain valves and

checking for the presence of water. If moisture is present,

the desiccant cartridge may require replacement; however,

the following conditions can also cause water accumulation

and should be considered before replacing the desiccant:

1. An outside air source has been used to charge the

system. This air did not pass through the drying bed.

2. Air usage is exceptionally high and not normal for a

highway vehicle.

This may be due to accessory air demands or some

unusual air requirement that does not allow the

compressor to load and unload (compressing and

non-compressing cycle) in a normal fashion. Check

for high air system leakage. If the vehicle vocation

has changed, it may be necessary to upgrade the

compressor size. Refer to Bendix Specification

BW-100-A / Appendix D, to determine if any changes

are necessary. Specication BW-100-A is available

from the Bendix TechTeam at 1-800-247-2725 or

bendix.com.

3. The location of the air dryer and reservoir system

is too close to the air compressor. Refer to Bendix

Specication BW-110-A / Appendix B, for discharge line

lengths.

4. In areas where more than a 30 degree range of

temperature occurs in one day, small amounts of water

can temporarily accumulate in the air brake system due

to condensation. Under these conditions, the presence

of small amounts of moisture is normal.

CARTRIDGE REPLACEMENT

Adhering to a preventive maintenance schedule is crucial to

keeping a vehicle’s air system clean and ensuring superior

performance of all components that utilize system air – such

as brakes, emissions equipment, and automated manual

transmissions. See Table 2 for Bendix AD-9si air dryer

recommended cartridge replacement intervals for vehicles

equipped with a Bendix

®

compressor.

More frequent intervals may be required depending

on a vehicle’s age, its compressor condition, use of a

non-Bendix compressor, the operating environment,

the vehicle’s vocation, and its usage. In conjunction

with these guidelines, fleets can determine the

functionality of their lters by checking for moisture in

the air brake system monthly. If moisture is present,

the air dryer cartridge may require replacement.

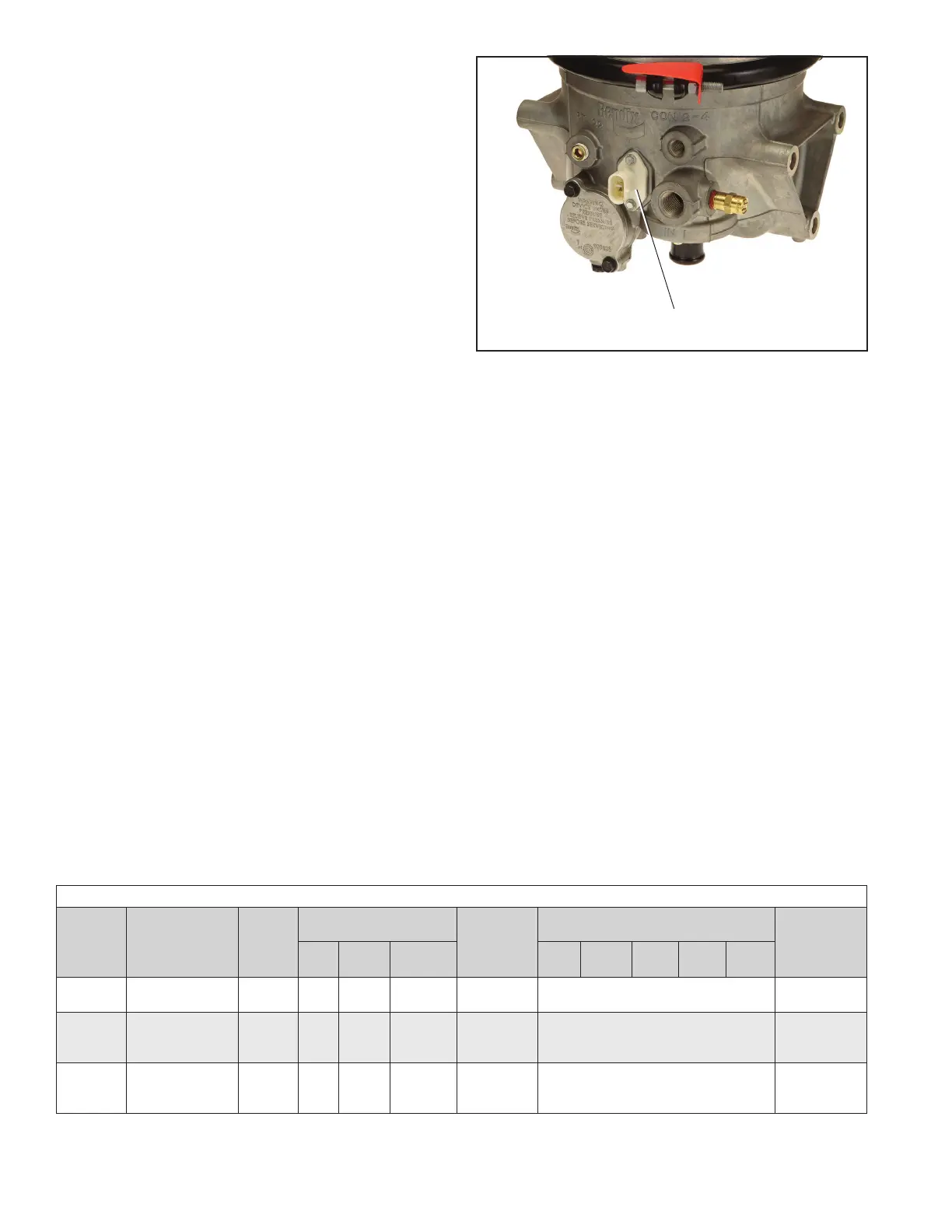

Figure 6 – Heater and Thermostat Connector

Heater & Thermostat

Connector

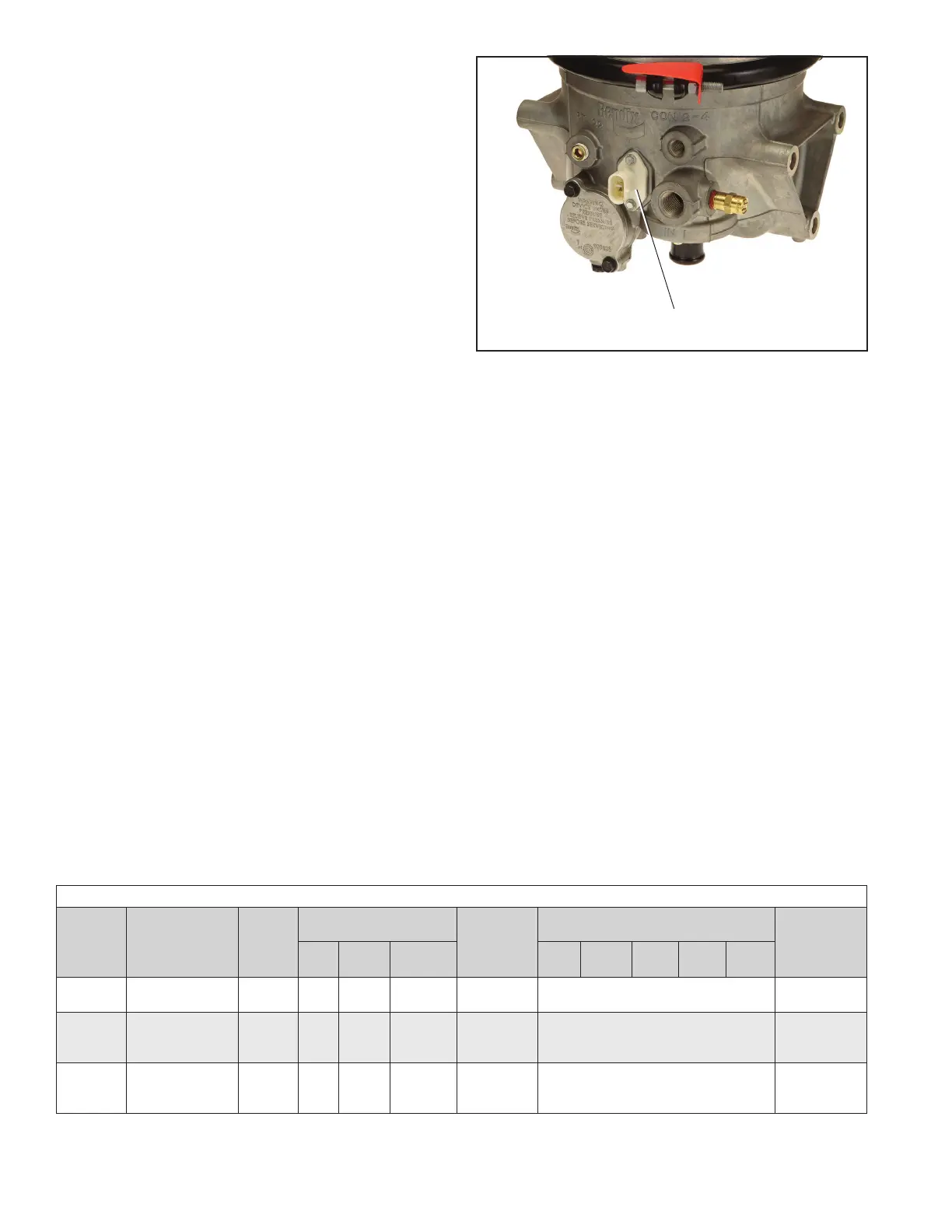

Table 2 – Service Intervals

Recommended Service Intervals for Bendix

®

Air Dryers

Air

Usage

Typical Vehicle

Vocation Axles

Reservoir Drain Interval

(whichever comes first)

Bendix

®

Standard

Cartridge

Replacement

PuraGuard

®

Oil Coalescing

Cartridge Replacement*

Bendix

®

GC

™

Green Cartridge

ReplacementHours Mileage Time AD-9

®

AD-9si

®

AD-IP

®

AD-IS

®

AD-SP

®

Standard

Line haul, city,

delivery

5 or less 900 25,000 3 months 24 months 24 months or 200,000 miles 12 months

Medium

Double trailers,

light transit, light

off-highway

8 or less 450 12,000 2 months 18 months 18 months or 150,000 miles 12 months

High

Multiple trailers,

city transit, heavy

duty off-road

11 or

less

300 6,000 1 month 12 months 12 months 6 months

*Always follow the truck manufacturer's published service recommendations as they may require more frequent services.

Loading...

Loading...