®

SD-03-812

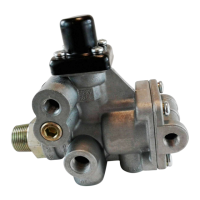

DESCRIPTION

The Bendix

®

E-2

™

and E-3

™

brake valves are single circuit

brake valves that provide the driver with single point control

of the service braking system. The valve can be either treadle

operated or fitted with a lever for a linkage connection to a

conventional brake pedal. Movement of the treadle or pedal

controls the graduated application and release of air pressure

to the vehicle brake actuators, applying or releasing the

vehicle brakes.

The E-2

™

and E-3

™

brake valves utilize a rubber spring

confined in a retainer, resulting in reduced plunger travel as

compared to previous design single circuit brake valves.

The E-3

™

brake valve differs from the E-2

™

valve in that it

employs a different piston (see insert Fig. 1), which requires

greater plunger travel. Because of the greater plunger travel,

the E-3

™

valve provides less sensitivity in the 0-40 psi

application range as compared to the E-2

™

valve. Other than

the different pistons, the E-2

™

and E-3

™

valves are identical.

An identification washer, located under the retaining ring in

the valve’s exhaust port, provides a means of identifying the

E-2

™

and E-3

™

brake valve.

The E-2

™

and E-3

™

valves have an insert type inlet/exhaust

valve assembly which can be removed without disconnecting

air lines. An exhaust check valve in the bottom of the insert

prevents contaminants from entering the valve through the

exhaust port. An optional exhaust extension is available

should an exhaust carry-off line be required.

Porting consists of two (2) 1/2 inch p.t. supply ports, four (4)

3/8 inch or 1/2 inch p.t. delivery ports, and two (2) 1/4 inch

p.t. accessory ports (in the supply portion of the valve).

OPERATION

Applying

Applying the treadle or pedal exerts a force on the plunger,

rubber graduating spring and piston. The downward

movement of the piston causes the piston stem (which is

the exhaust seat) to contact the valve, closing the exhaust.

As the exhaust closes, the inlet valve moves away from its

seat. Air pressure is then allowed to flow by the inlet valve,

out the delivery ports and to the brake actuators, applying

the brakes.

Balanced

When the air pressure in the cavity beneath the piston and

the air pressure being delivered to the brake actuators equals

the mechanical force on the top of the piston, the piston

lifts and the inlet valve closes, cutting off any further flow of

air from the supply line through the valve. The exhaust

remains closed, preventing any escape of air through the

exhaust port.

Bendix

®

E-2

™

& E-3

™

Brake Valves

FIGURE 1 E-3

™

BRAKE VALVE (SECTIONAL VIEW)

RETAINER

O-RING

PISTON

RETURN

SPRING

RETAINING

RING

PRELOAD

SPRING

EXHAUST CH.

VALVE SEAT

INLET/EXHAUST

VALVE

CAP SCREW

INSERT ASS’Y

SPRING SEAT

WASHER

RUBBER SPRING

RETAINER

VALVE SPRING

O-RING

O-RING

DIAPHRAGM

WASHER

SCREW

11

10

6

2

3

1

4

12

8

9

21

20

19

18

17

16

15

14

13

MOUNTING

PLATE

TREADLE

AUXILIARY

PORTS (2)

DELIVERY

PORTS (4)

EXHAUST

SUPPLY

PORTS (2)

7

PISTON

E-2

™

- E-3

™

BRAKE VALVE

Loading...

Loading...