18

SECTION 9

(TESTING PROCEDURES)

Single Column Test

(Repeat these procedures on each Column in Single

Mode.)

Lifting Test

1. After setting the Operation Mode to SINGLE on the

control panel, raise the lift unloaded by pressing and

holding the “UP” button to check if the carriage rises

normally.

If the Carriage raises slowly or jerks, the Cylinder may

have to be bled to release any trapped air in the hydraulic

system. If not, go to Step 3.

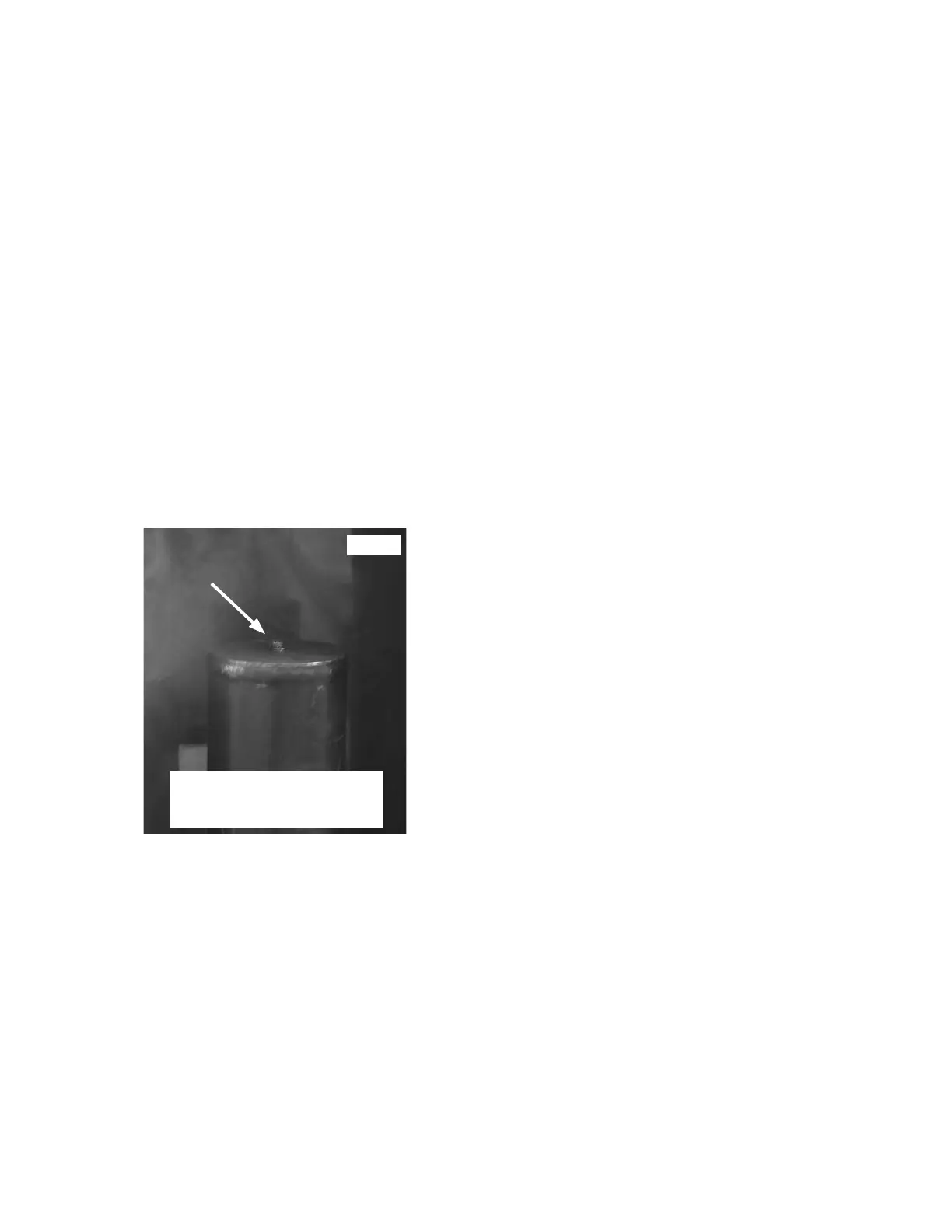

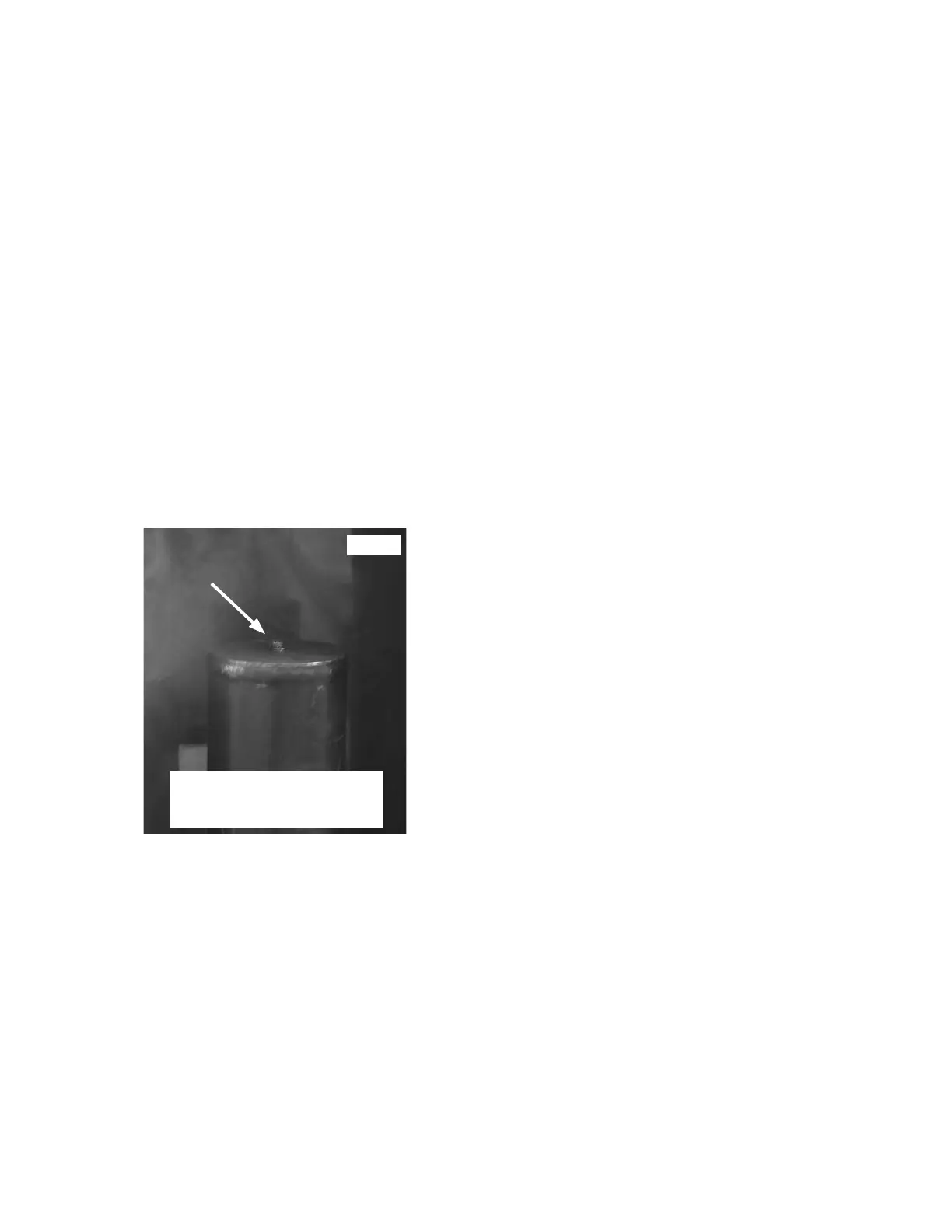

2. Raise the carriage above about 5”\127mm and

loosen the Cylinder Bleed Screw on the top of the

Cylinder one full turn or until air or oil ows out. DO NOT

completely remove bleed screws. Retighten after trapped

air has escaped. (See Fig 9.1)

Safety and Lowering Test

3. With the Carriage above 21”/533mm press and hold

the “PARK” button that became available when the lift

passed the indicated height. The lift will lower onto the

nearest safety lock. Continue holding the “PARK” button

and then check that the Carriage is securely on the safety

lock before continuing.

NOTE: When the PCL-18B is not loaded with a vehicle

the SPEED should be set to Rabbit mode or a fault

condition may be detected.

4. Press and hold the “DOWN” button. The carriage will

start to move up to clear the safeties and then down to the

to the ground or until the “DOWN” button is released.

Emergency Button Test

5. Test the Emergency Stop Button by hitting the

Emergency Stop Button while the lift is rising or lowering.

The lift should immediately stop. To Reset, twist button

clockwise. The button will pop back out.

Multiple Column Test

Repeat the Lift Test, Safety Test, Lowering Test, and

Emergency Stop Button Test procedure for each of the

other Columns in the other Operation Modes: Pair and

Team.

Remember:

-Pair mode will control the Column directly across

from the Column control panel being operated.

-Team mode will control the entire system.

POST-INSTALLATION CHECK-OFF

√ Columns properly lowered and stable.

√ Wheel and Arm Pins properly attached.

√ Electric power supply confirmed.

√ Safety Locks functioning properly.

√ Check for hydraulic leaks.

√ Oil level.

√ Lubrication of critical components.

√ Check for overhead obstructions.

√ All Screws, Bolts, and Pins securely fastened.

√ Surrounding area clean.

√ Operation, Maintenance and Safety Manuals

on site.

√ Perform an Operational Test with a typical

vehicle.

DO NOT completely remove

Bleed Screw. One full turn

should purge trapped air.

Cylinder Bleed

Screw

Fig. 9.1

Loading...

Loading...