17

SECTION 8

(INITIAL START-UP AND PLC SYSTEM OVERVIEW)

1. Make sure the power unit reservoirs are full with four

(4) gallons of 10-WT hydraulic oil or Dexron-III automatic

transmission uid each.

2. Apply light axle grease to the inside of the posts where

the slide blocks glide.

3. Once electrical power is connected to Column A and

the communication cables routed to the other Columns,

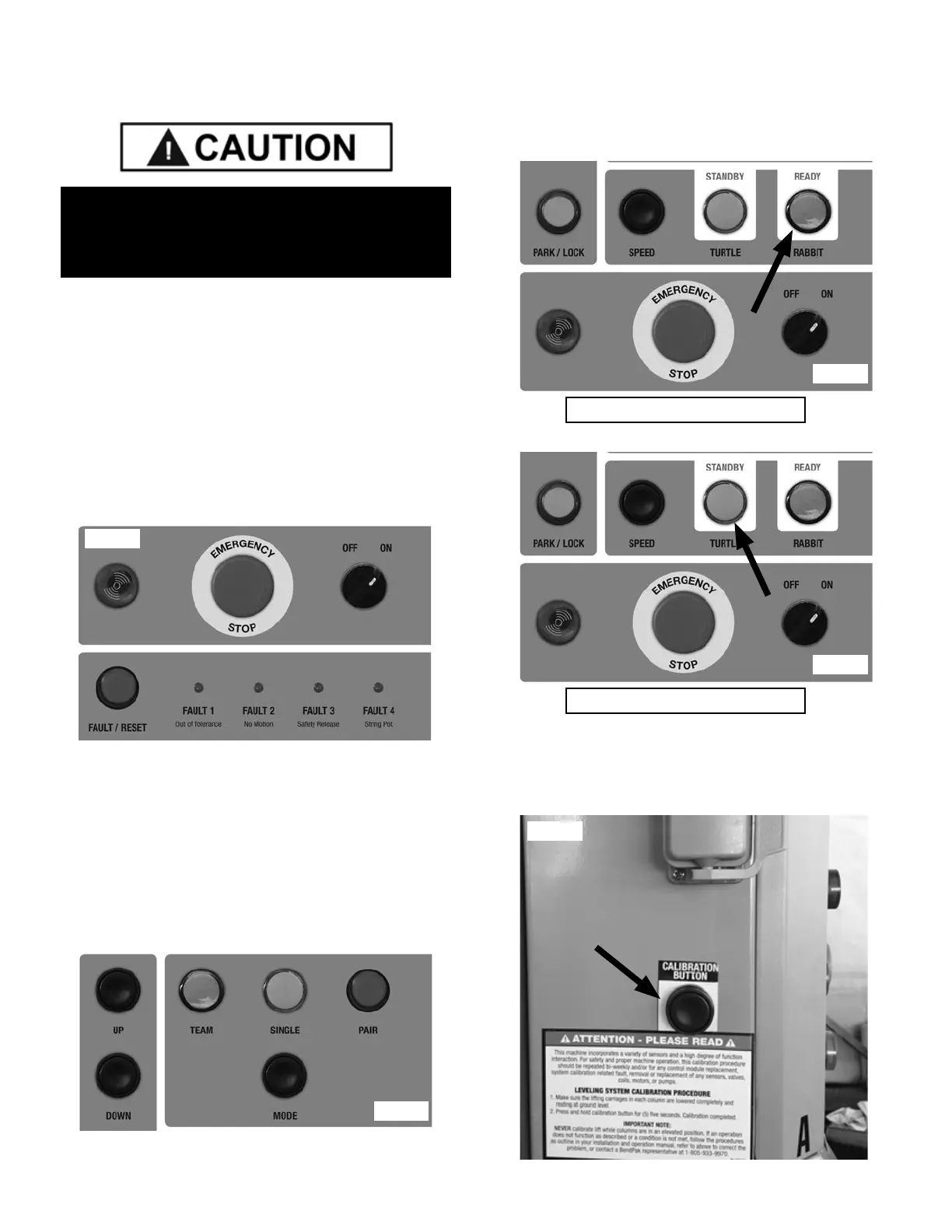

turn the Main Power Switch to the “ON” position. (See

Fig. 8.1)

If any of the Column heights are higher than the other one

press the “DOWN” button. If the heights still do not match

correctly see Maintenance section for calibration

instructions.

5. Pressing MODE allows the operator to control he

movement of the entire system in Team mode (See Fig

8.2), Columns A and B in Pair mode or Column A by itself

in Single Mode

6. Pressing SPEED allows the operator to change the

speed at which the lift will lower when the DOWN button is

pressed. Rabbit mode (See Fig. 8.3) allows for a quicker

descent while Turtle mode (See Fig 8.4) allows for a

slower, more precise descent.

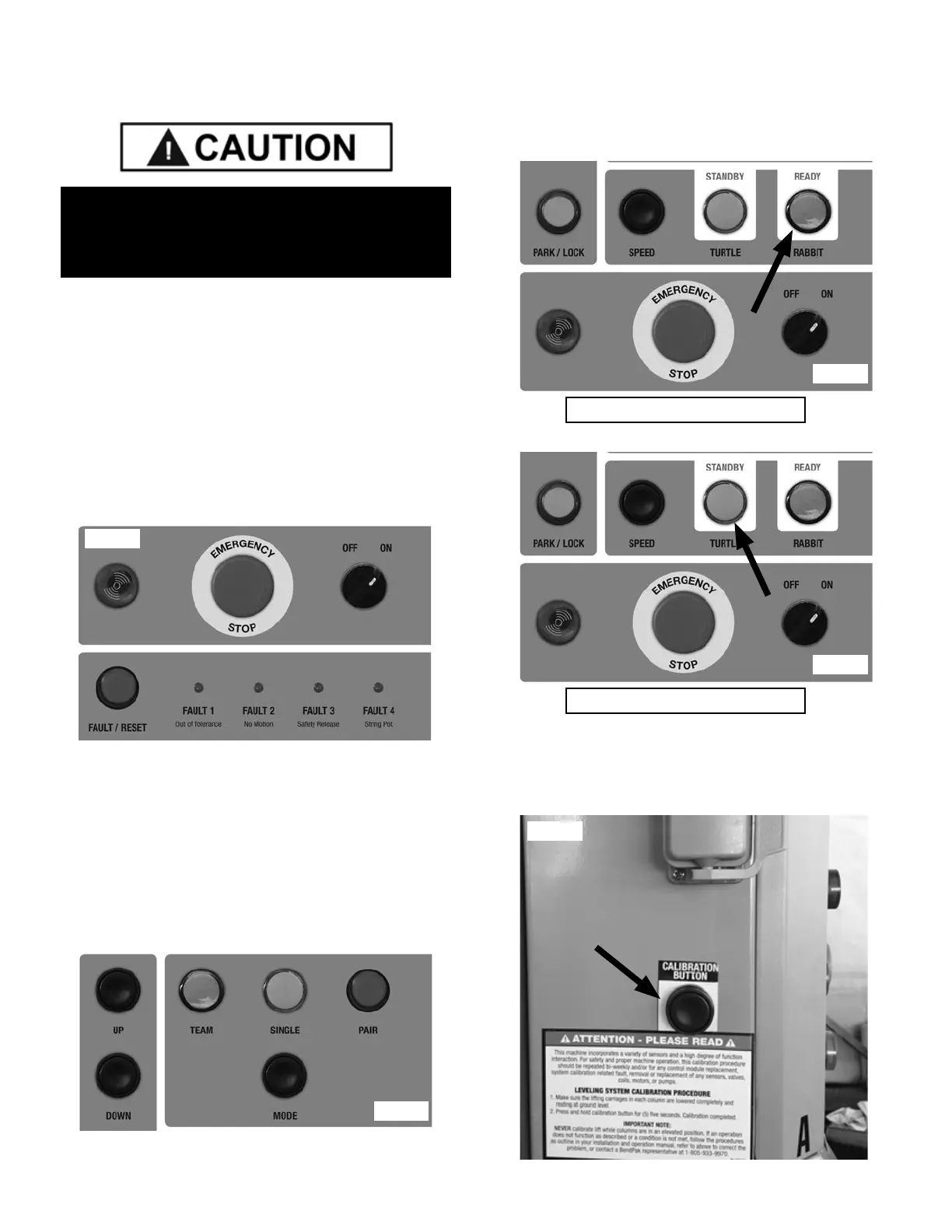

7. Pressing CALIBRATE SYSTEM (Column A Control

Panel only) will set the current height of the lift carriages

as the 0 point or ground level. (See Fig 8.5)

ENSURE ALL OF THE COLUMNS ARE IN THE

LOWERED POSITION AND NOT RESTING ON A

RAISED HYDRAULIC JACKING DOLLY.

Fig. 8.1

Fig. 8.2

Rabbit Mode

Turtle Mode

Fig. 8.3

Fig. 8.4

Fig. 8.5

Loading...

Loading...