manual. Any such parts will undergo

inspection to verify the claim. Replacement

parts supplied prior to this may be charged,

and a credit supplied upon subsequent

validation of the warranty claim.

Consumable items are specifically not

included within the scope of the warranty.

Note (iii)

Notification is required immediately a fault is

suspected.

The manufacturer will not accept

responsibility for any additional damage that

has been caused, expense incurred, or

consequential loss resulting from any failure

of the heater(s).

SPECIAL RISK AREAS

Where it is proposed to install a heater

within a special risk area (e.g. an area

containing flammable vapours where petrol

engined vehicles are stored parked or

serviced where paint spraying occurs, or

where woodworking machinery or other

flammable dust creating process’s are

employed then restrictions, additional

regulations concerning the heater flue wiring

or controls may apply.

It is strongly recommended that you contact

Benson Technical before installation

Caution

When used in room sealed mode it may be

possible to install Variante heaters in areas

containing flammable vapours, high levels of

airborne dust combustible dust chlorinated or

halogenated hydrocarbons degreasing

solvents styrenes other laminating materials

or airborne silicones. Benson Technical

should be contacted before installation .

Failure to do so may invalidate or reduce

guarantee cover.

2.0 Installation

The location chosen for the heater must

allow for the fitting of an effective flue

system.

The location must also allow for adequate

clearance for the air supply, return air

circulation, gas supply, electrical supply,

whilst also providing good and safe working

access.

The heater must be installed so that it is

level, supports for the heater must be

sufficiently robust to withstand the weight of

the heater and any ancillary equipment

Any combustible material adjacent to the

heater or flue system must be so placed or

shielded so that its surface temperature does

not exceed 65

0

C. Generally a free blowing

heater should be located at a height

(measured from floor level to the base of

unit) as detailed within section 2.1

VRABD free blowing heaters are at their

most effective when located as close to the

working area as possible. However care

should be exercised to avoid directing the

discharged air directly onto the occupants of

the area to be heated.

Where the passage of cold air causes

problems (e.g. by entrances, loading bays

etc) it is considered favourable if the heater

is positioned so as the discharge towards or

across the cold air source from a distance

from 1.5m - 6m dependent upon the size of

the entrance and the air throw characteristics

of the heater. On exposed walls heaters

should be positioned so as to discharge

towards, or along the length of the exposed

wall.

In areas where it is proposed that more than

one heater is to be installed, a general

scheme of circulation should be drawn up

and maintained, thereby offering the best

heat distribution. Air pressure within the area

heated and the outside air pressure must

remain the same, factors influencing this

would be the presence of extraction systems,

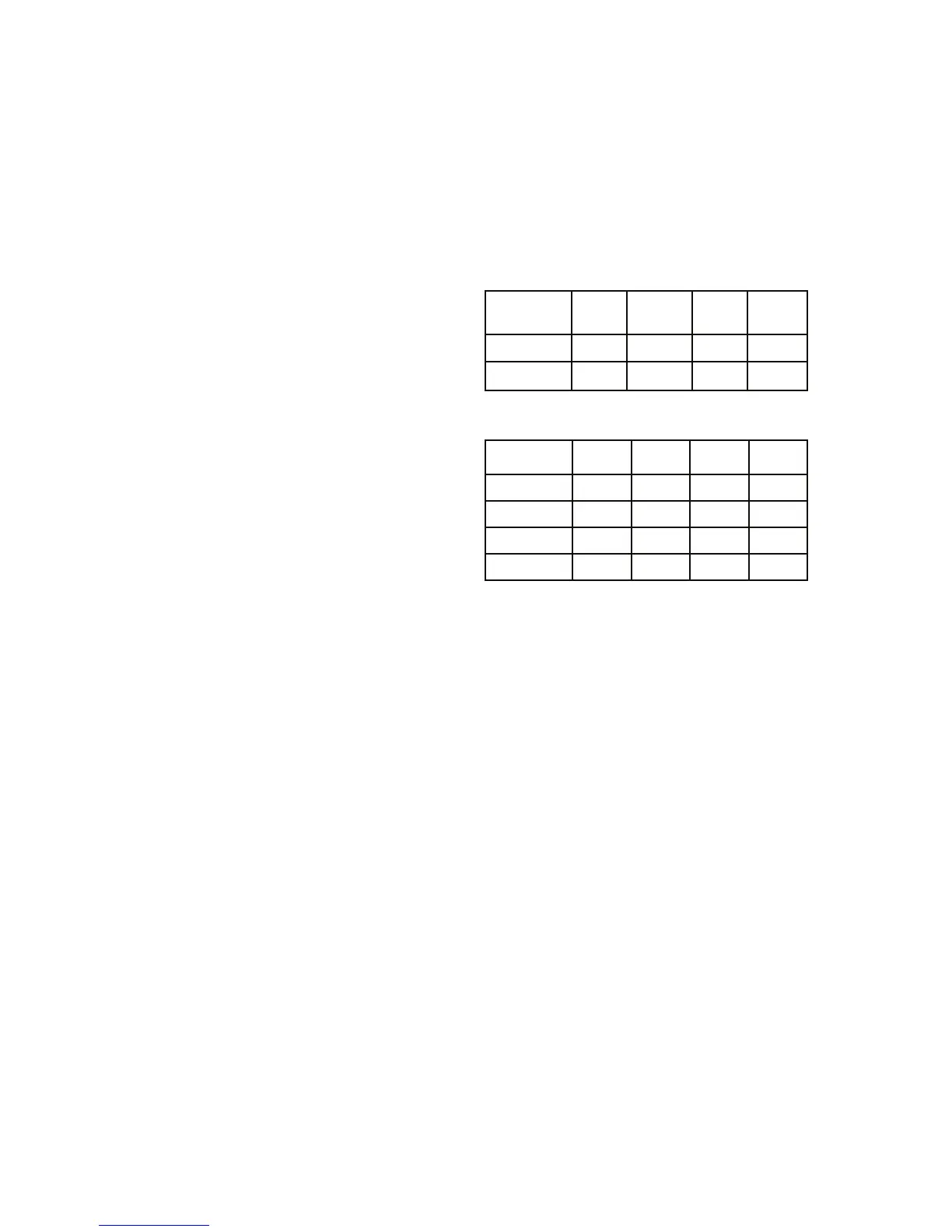

Model

VRA/C

250 330 410 490

Min 2.4 2.4 2.4 2.4

Max 5.0 5.0 5.0 5.0

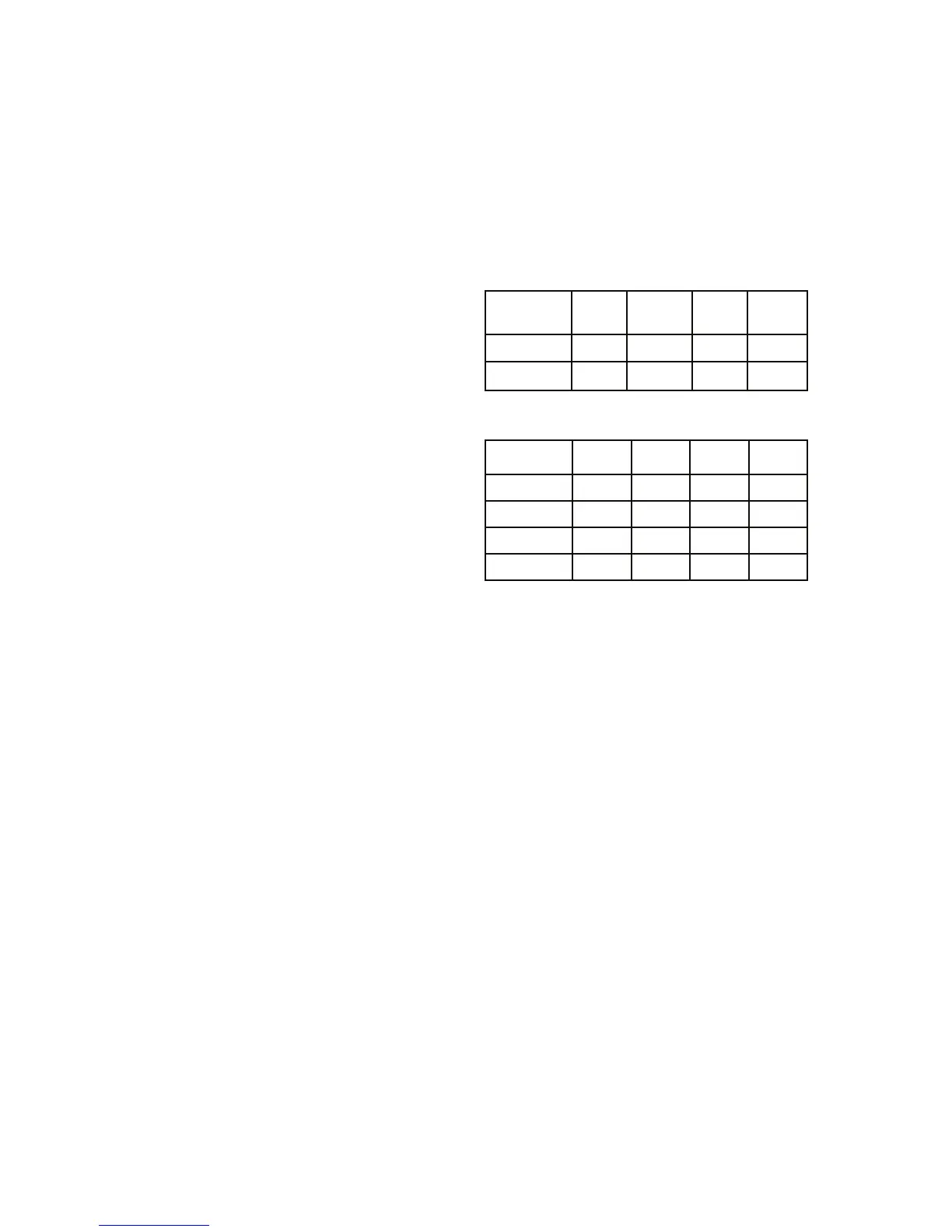

Model 250 330 410 490

Above

300 300 300 300

Below

300 300 300 300

Right side

250 250 250 250

Left side

950 950 950 950

Clearances VRABD in mm

Left hand side = burner compartment side

Loading...

Loading...