4

Status mode selection MOdE: rotate to change the thermostat mode

between AUTO, PARTY, and OFF, press to save. The press from

status mode automatically escapes from menu.

Economy temperature selection ECOt: Rotate to select the desired

economy temperature and press to enter. This temperature is used

when programming time is OFF in AUTO status mode.

Heating and cooling mode selection I- - S: Rotate to select the ther¬-

mostat mode between I (heating) and S (cooling), press to save.

The selected mode is identied on the display with the presence of

the radiator icon in AUTO mode (radiator icon ON means heating

mode, radiator icon OFF means cooling mode). In cooling mode the

request versus the chiller appliance remain ON till the room temper-

ature moves below the target.

Time of the day: rotate to change the hours, press to save. Move to

minutes; rotate to change minutes, press to save.

Day of the week: rotate to change the day, press to save

Programmed times day 1-7: rotate clockwise to set hour ON, rotate

anticlockwise to select hour OFF. Clockwise and anticlockwise rota-

tion move ahead the time. Press to save. Rotate clockwise to move

to the following day. It is possible to program together days 1…5 and

days 6-7 with the same pattern in a single operation.

PL: rotate to select the password value, press to enter inside the

technical menu. Rotate to select the parameters:

1 = COUP - ENCODING between the receiver and the transmitter

2 = CH - RADIO FREQUENCY modication

3 = frost protection temperature selection

4 = hysteresis ON value selection

5 = hysteresis OFF value selection

6 = SENS – TEMPERATURE SENSOR ON-OFF. The temperature

sensor can be activated or deactivated

7 = calibration of the temperature sensor

Exit: escape from main menu.

INSTALLATION AND OPERATING INSTRUCTIONS

Unlike the conventional thermostat, this control separates the func-

tion in two units. The receiver serves for wiring connections and

heat on/off control. The transmitter serves as the user interface and

for temperature sensing/control. The two units are linked by radio

frequency (RF). The RF communication is two directions from the

transmitter to the receiver; therefore if transmitter-receiver are not

coupled, alarm of missing communication is visible on the transmit-

ter display.

THE TRANSMITTER is a wall-mounted thermostat. The transmitter

can be located wherever a conventional room ther-

mostat would normally be sited. No wiring is re-

quired, as the transmitter is battery powered.

THE RECEIVER is connected to the boiler, and can

replace a conventional mechanical or electronic time

clock. The receiver arrives pre-cabled and ready to

be xed, therefore it is not necessity to open the re-

ceiver casing. The receiver is equipped with a trans-

parent bubble button that incorporates the button

function, the green led function and the red led function.

Button functions:

1. Press once: manually switch ON the heating (relay closed), press

again to switch OFF.

2. Press for 3 seconds: encoding procedure start up. After success

coupling there is an automatically exit from the procedure (see the

PL menu at point 1-COUP).

Receiver led: colors and functionality

RED LED GREEN LED REASON

ON xed Blinking Relay ON or coupling procedure

Blinking ON xed Relay OFF

OFF

Blinking

irregularly

Relay ON - no RF communication (low

batteries on the transmitter or transmitter

too far from the receiver)

Blinking

irregularly

OFF

Relay OFF - no RF communication (low

batteries on the transmitter or transmitter

too far from the receiver)

NOTE 1 FOR RECEIVER: when the receiver is manually moved to

the ON or OFF relay position (heating request ON or OFF), after few

seconds (at least 100 secs.) the relay position will move according

the transmitter request. If it is required for a permanent ON or OFF

position, please use the transmitter functionality.

NOTE 2 FOR RECEIVER: in case of missing radio communication

(see errors paragraph), the receiver relay moves automatically to the

ON position (after 10 minutes of missing communication) whatever

the transmitter request was (led green irregularly blinking). However

it is possible manually move the relay position (the heat request) to

the OFF or ON position permanently by pressing the receiver trans-

parent button. The selected position is indicated by the red or green

light irregularly blinking. Once the radio communication has been

reactivated the receiver will revert to work according the transmitter

requests.

PACKING LIST QTY

RF receiver with 6 wire cable tted 1

RF transmitter 1

Screws and wall plugs (drill 5 mm) 2

Adhesive magnetic tted 1

Double side adhesive 2

Instructions 1

Batteries 1,5 AAA 2

BOILER PREPARATION

Isolate the appliance from the electrical supply and remove the ap-

pliance casing and PCB cover (refer to boiler installation instructions

for specic details).

The receiver can be provided with or without a male plug according

the product code ordered and according the availability of female

counterpart on the boiler side. The version without male plug is sup-

plied with spade terminals.

Receiver with male plug tted

Connect the male plug (4 pins) of the receiver to the

female plug on the boiler (pre-wired on specic boiler

models).

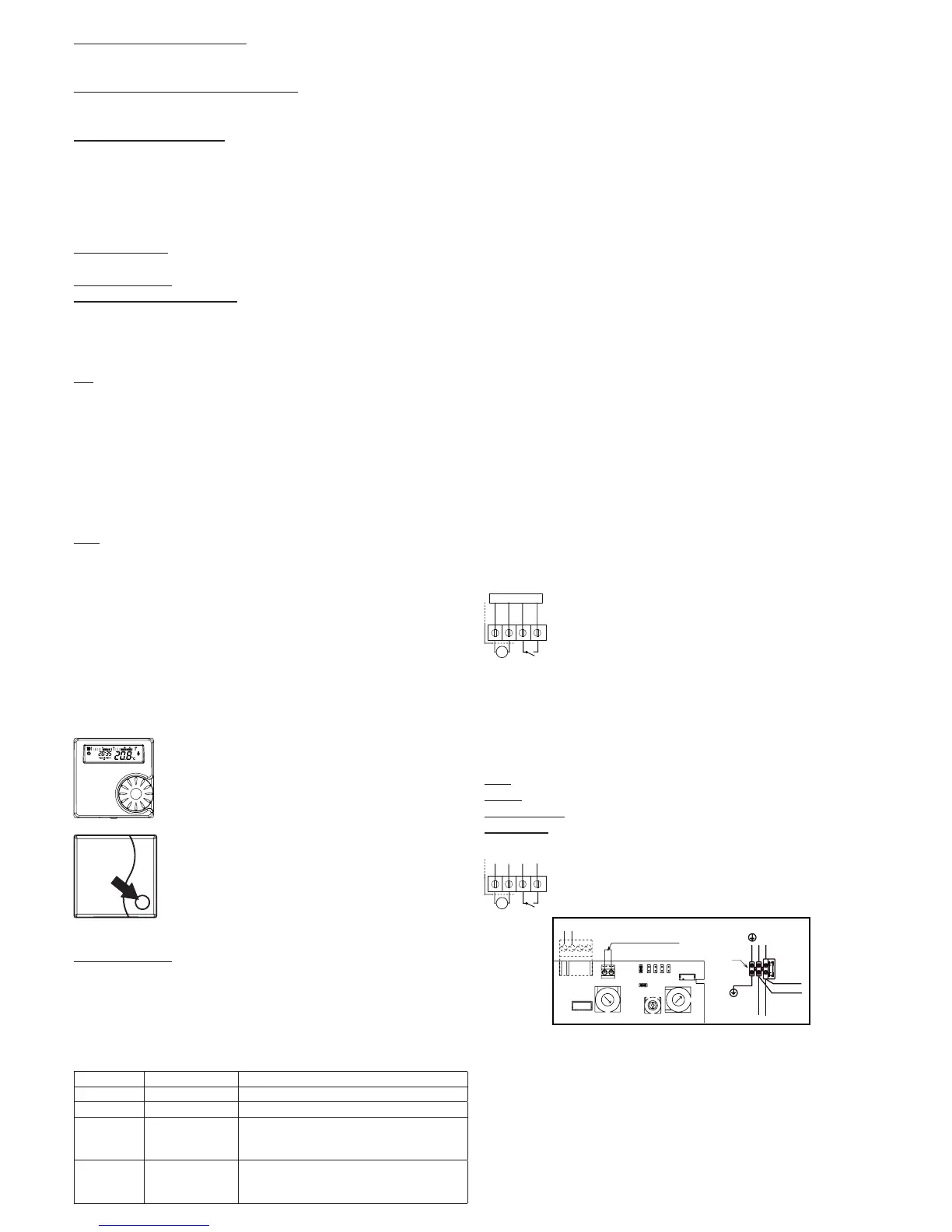

Receiver with spade terminals

Connect the spade terminals from the receiver to the PCB terminals

(room thermostat terminal black & black, open term (OT) bus red

& red (alternative to room thermostat connection), main supply

terminals blue and brown on the main boiler supply socket) - gure

below for a sample boiler connections.

Blue = main supply 230 Vac = neutral N

Brown = main supply 230 Vac = line L

Black & Black = room thermostat = I-O (TA)

Red & Red = OpenTherm = OT bus

See picture for the receiver internal connections.

JP1

JP2

JP3

JP4

JP5

JP6

CN6

CN5

CN12

1

CN13

P1

P3

P2

Remove the bridge

Black RF wires connections

N

L

230 V

M3

F

brown

blue

brown RF

blue RF

IMPORTANT: the link-wire (if tted) must be removed from room

thermostat terminals

IMPORTANT: Secure the receiver wiring harness to the internal boil-

er cable anchors.

INSTALLATION OF RECEIVER

Secure the receiver in the proximity of the boiler using the screws

and wall plugs or using the adhesive magnetic strips on the external

boiler casing including to x (both xing tools are provided).

black

L

N

I

O

black

blue

brown

Loading...

Loading...