INSTALLATION AND MAINTENANCE MANUAL

Emergency/Remote Shutdown Air Valves

Betts Industries Inc. ▪ 814·723·1250 ▪ 1800 Pennsylvania Ave. West ▪ Warren, PA 16365 ▪ www.BettsInd.com

Print Date: 11/21/2023 This form is considered uncontrolled 24 hrs. after print date.

5.2 Field Testing (monthly testing)

5.2.1 Visual inspection:

5.2.1.1 Inspect exterior of valve for corrosion or damage. Pay special

attention to the area where the stem moves in and out of the bushing.

5.2.1.2 Inspect for any air leaking at any of the fittings, at the stem or end cap.

5.2.1.3 Look for leakage of fluid out of exhaust port. This could be an

indication of a seal failure in one of the Emergency Valves or Air

Manifold. Investigate and repair the problematic component.

5.2.1.4 Ensure the end cap is snapped into the back of the valve and ensure

that the vent hole in the end cap is not plugged or blocked.

5.2.1.5 Inspect exhaust port and make sure it is unobstructed and oriented in

an area that is protected from weather, debris or moisture.

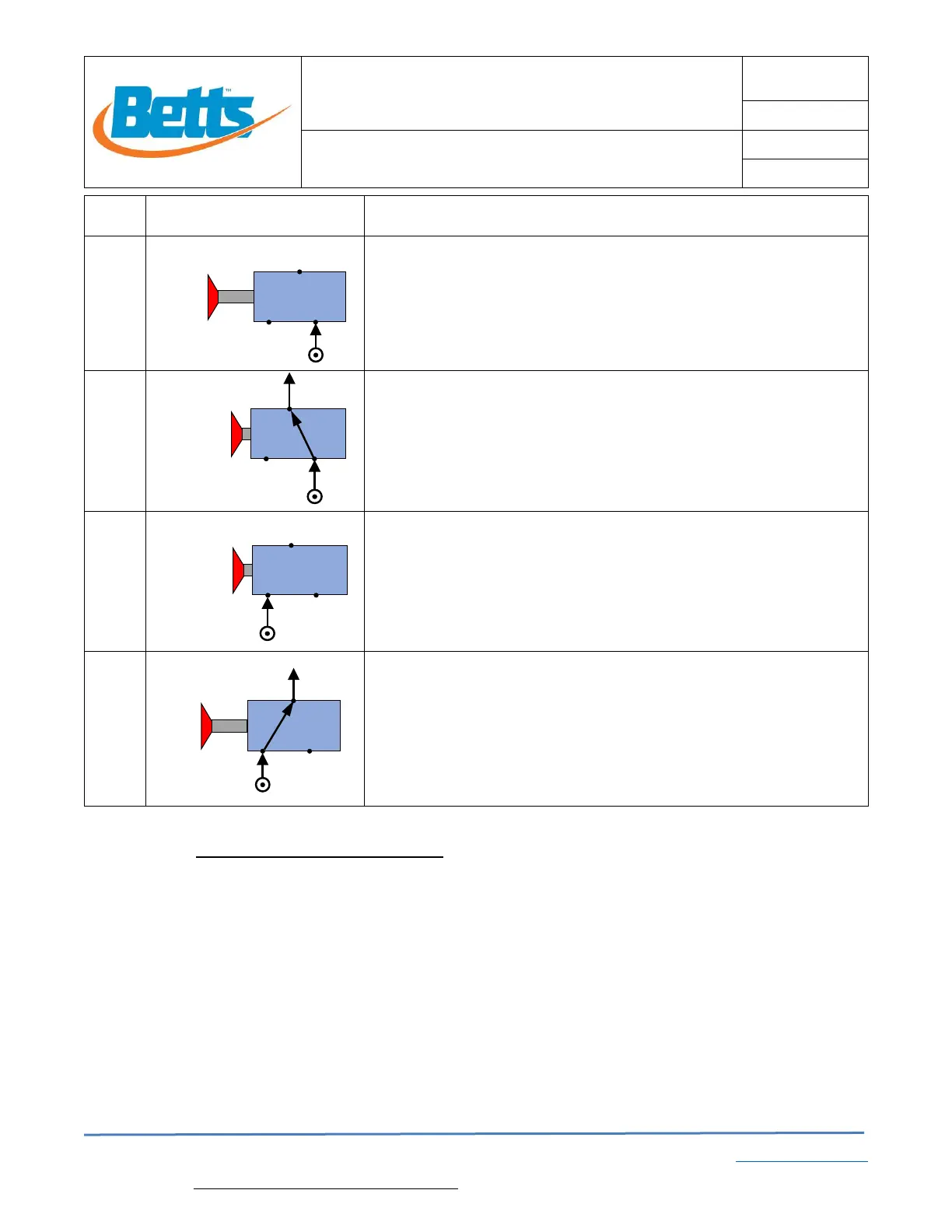

1. Port 1 blocks pressure.

2. No leakage at port 2 or 3.

3. No leakage between the End Cap and the Body or out the

hole in the End Cap.

4. No leakage between the stem and the front of the body.

1. Port 2 expels pressure.

2. No leakage at port 3.

3. No leakage between the End Cap and the Body or out the

hole in the End Cap.

4. No leakage between the stem and the front of the body.

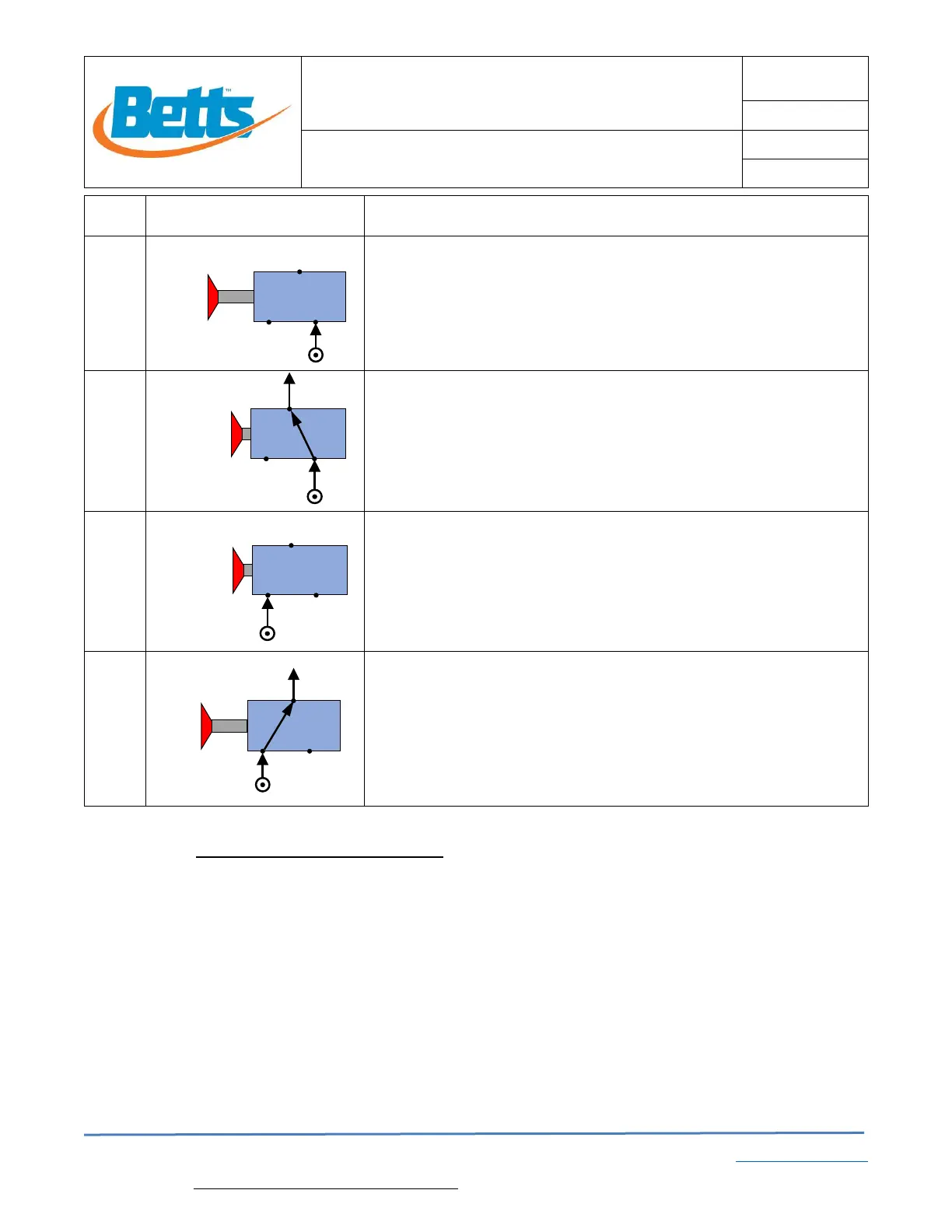

1. Port 3 blocks pressure.

2. No leakage at port 1 or 2.

3. No leakage between the End Cap and the Body or out the

hole in the End Cap.

4. No leakage between the stem and the front of the body.

1. Port 2 expels pressure.

2. No leakage at port 1.

3. No leakage between the End Cap and the Body or out the

hole in the End Cap.

4. No leakage between the stem and the front of the body.

Loading...

Loading...